Adhesive bandage film, adhesive bandage and preparation method of adhesive bandage film

A band-aid and film-forming technology, which can be used in pharmaceutical formulations, medical preparations with inactive ingredients, and digestive systems, etc., and can solve problems such as oral hygiene effects, residual hazards, and absence of market costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

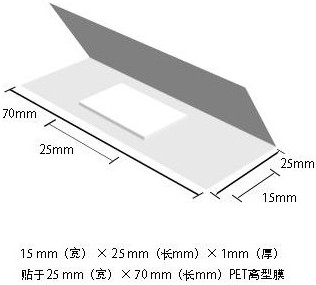

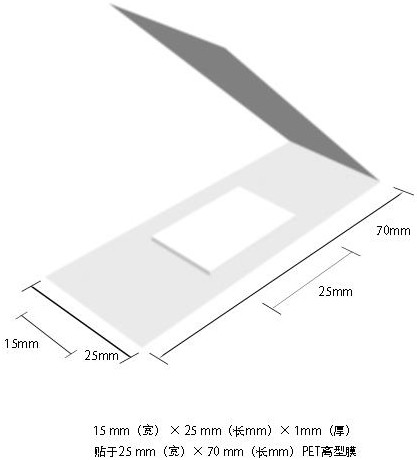

Image

Examples

Embodiment 1

[0040] Step 1 prepares film-forming solution:

[0041] According to the ratio of 3 wt% and 10 wt%, weigh 3 g of hydroxyethyl cellulose (Shandong Jurong Biological Industry Co., Ltd.) and 10 g of glycerin, stir them well, add water to 100 g, and place in a water bath at 60 °C Stir evenly to form a clear and transparent solution, and stand for defoaming before use.

[0042] Step 2 Cross-linking to form a film:

[0043] Use a bottom area of 40 cm 2 , thickness 2 cm, cuboid stainless steel mold, take an appropriate amount of film-forming solution to cover the film, scrape it flat, dry at 45 ℃, and perform physical cross-linking to form a film. Add 50g and 100g of film-forming solution respectively, and adjust the film thickness by controlling different addition amounts to prepare films of 1mm and 2mm. After drying, the film is colorless, transparent, viscous and colloidal. When pressed by hand, the surface is very soft. After the pressure is removed, it can return to its orig...

Embodiment 2

[0061] Step 1 prepares film-forming solution:

[0062] According to the ratio of 2 wt% and 5 wt%, weigh 2 g of hydroxyethyl cellulose (Shandong Jurong Biological Industry Co., Ltd.) and 5 g of glycerin, stir them well, and add 10% functional excipients of HEC content Collagen 0.2g, add water to 100g, stir in a water bath at 60 ℃ to evenly form a light yellow clear and transparent solution, stand for defoaming and set aside for use.

[0063] Step 2 Cross-linking to form a film:

[0064] Use a bottom area of 40 cm 2 , thickness 2 cm, cuboid stainless steel mold, take an appropriate amount of film-forming solution to cover the film, scrape it flat, dry at 45°C, and perform physical cross-linking to form a film. After drying, the film is yellowish transparent and viscous gelatinous film. Compared with the film in Example 1, the 2:5 ratio film has a harder texture, but is still very soft and has no deformation after being stressed. The main reason for the yellowing of the pro...

Embodiment 3

[0081] Step 1 prepares film-forming solution:

[0082] Configure HEC and sodium carboxymethyl cellulose (Shanghai Changguang Enterprise Development Co., Ltd.) according to a mass ratio of 10:1, and mix to form a uniform solid component A. According to the ratio of 2 wt% and 10 wt%, take 2 g of component A and 10 g of glycerin, mix evenly and add water to 100 g, stir in a water bath at 60 °C to form a light yellow clear and transparent solution, and let it stand for defoaming before use.

[0083] Step 2 Cross-linking to form a film:

[0084] Use a bottom area of 40 cm 2 , thickness 2 cm, cuboid stainless steel mold, take an appropriate amount of film-forming solution to cover the film, scrape it flat, dry at 70°C, and perform physical cross-linking to form a film. After drying, the film is colorless, transparent, viscous and soft gelatinous film. Compared with the film in Example 1, the hardness is greater, and there is no deformation after being stressed.

[0085] Step 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com