Preparation process of lithium difluoro (oxalato) borate

A technology for preparing lithium difluorooxalate borate, which is applied in the fields of compounds containing group 3/13 elements of the periodic table, chemical instruments and methods, organic chemistry, etc., can solve the problem of low purity and complex preparation process of lithium difluorooxalate borate , Lithium difluorooxalate borate can not be applied on a large scale, etc., to achieve the effect of less impurities, simple purification method, and less side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

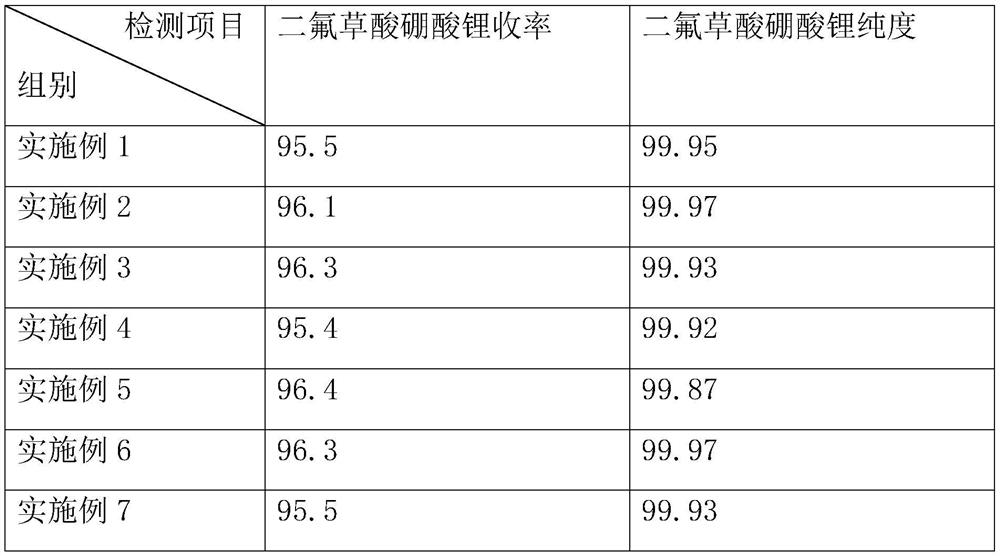

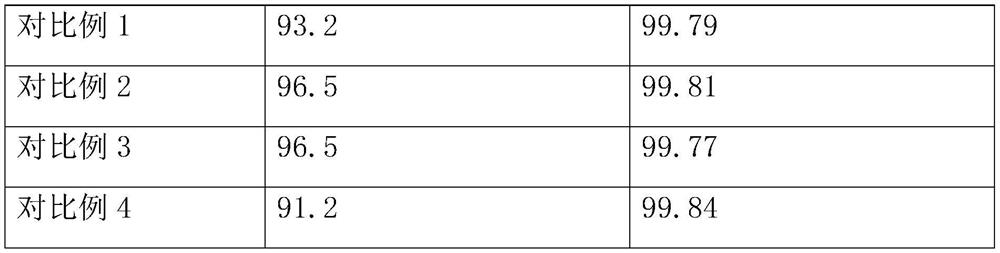

Examples

Embodiment 1

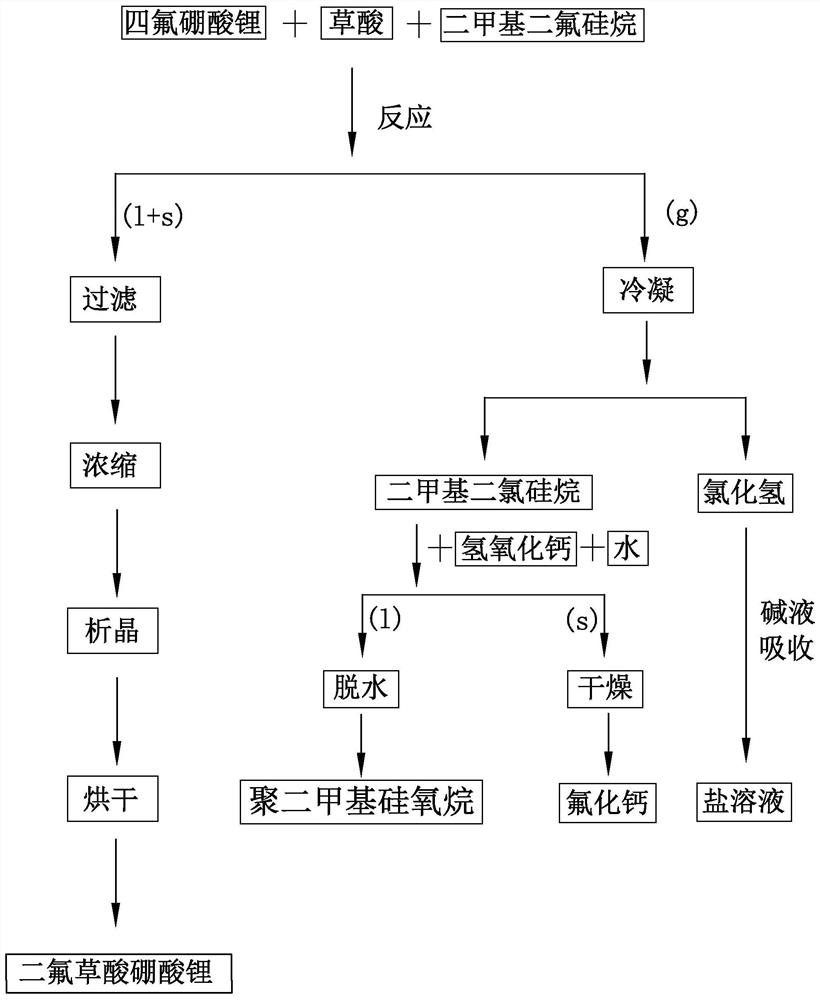

[0045] A preparation process for lithium difluorooxalate borate, comprising the following steps:

[0046] S1, reaction, the raw material dimethyl dichlorosilane 100kg, oxalic acid 90kg, lithium tetrafluoroborate 94kg are added in the dimethyl carbonate of 500kg, react 6h, reaction equation is as shown in reaction formula (1), reaction temperature is 57 ℃;

[0047] (Me) 2 SiCl 2 +H 2 C 2 o 4 +LiBF 4 →LiBC 2 o 4 f 2 +(Me)2 SiF 2 +2HCl (1)

[0048] S11, absorb the gaseous dimethyldifluorosilane and hydrogen chloride generated by the reaction in S1, and pass it into a condenser to condense. The condensation medium is a mixture of ice and water. After the dimethyldifluorosilane is condensed into a liquid state, it is separated from the gaseous hydrogen chloride. Methyldifluorosilane and hydrogen chloride were stored separately for subsequent by-product preparation.

[0049] S2, filtering, after the material is filtered after the reaction of S1, the filtrate is obtained,...

Embodiment 2

[0066] The difference from Example 1 is that 375kg of dimethyl carbonate was evaporated in step S3 of this example.

Embodiment 3

[0068] The difference from Example 1 is that 400kg of dimethyl carbonate is evaporated in step S3 of this example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com