Foam base material for anti-millimeter wave radar camouflage net and processing technology of foam base material

A technology of millimeter-wave radar and processing technology, which is applied in the field of camouflage nets, can solve the difficult problems of complete shielding of millimeter-wave radar, and achieve the effect of light weight, thickness control, and easy thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

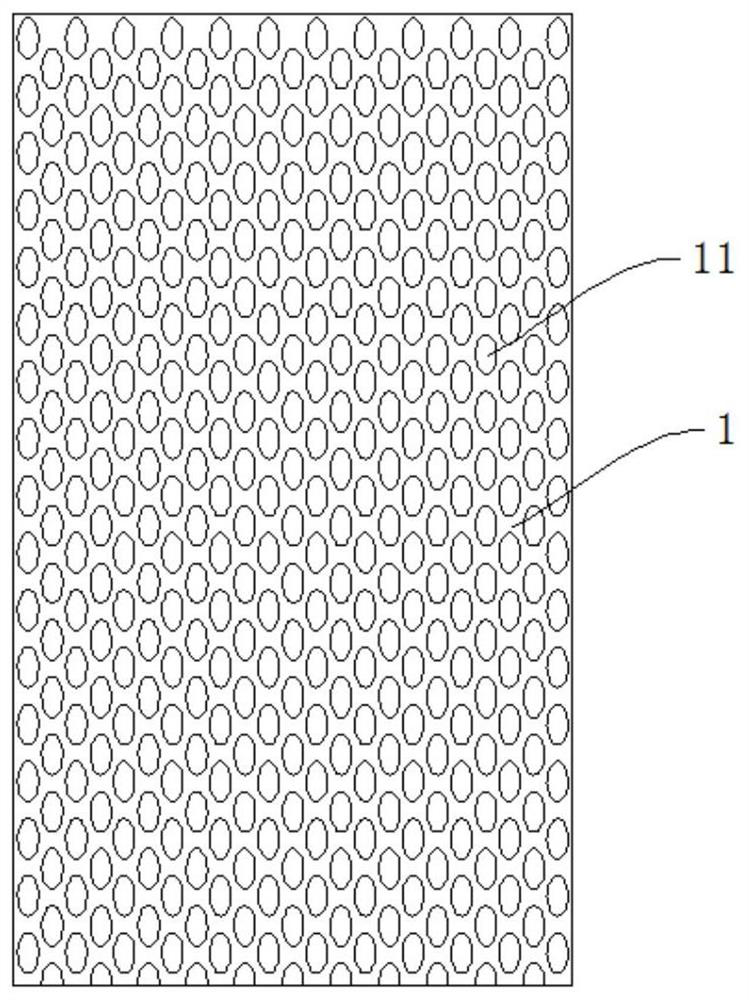

[0029] A foam base material for an anti-millimeter wave radar camouflage net, the foam base material is formed by mixing the following components:

[0030] 70 parts by mass of polyolefin, 8 parts by mass of modified carbon nanotubes, 4 parts by mass of modified graphene, 4 parts by mass of rare earth, 8 parts by mass of melamine flame retardants, 8 parts by mass of nitroso Foaming agent, 10 parts by mass of dialkoxy acetophenone sensitizer and 4 parts by mass of dibutyl hydroxytoluene antioxidant.

[0031] Add the above ingredients into the mixer and mix them evenly. Before mixing, the polyolefin needs to be ground into powder, and the particle size is 7000-8000 mesh. Add 0.5% titanate to the modified carbon nanotubes and modified graphene before mixing. Coupling agent, 0.2% cationic quaternary ammonium salt antistatic agent for dispersion modification.

[0032] Then the mixture is sent to a tablet extruder to be extruded into flakes.

[0033] The above sheets were irradiate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com