Silicon dioxide coating additive with ultraviolet absorption function and preparation method of silicon dioxide coating additive

A technology of silica and additives, which is applied in the field of coating additives, can solve the problems of restricting the application of coatings, and achieve the effects of good ultraviolet absorption characteristics, high grafting success rate, and good oil solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] As a carbonaceous raw material with glucose, glucose and ethylenediamine, orthosilicate as a raw material for preparing silica-carbon quantum dot composites, and the silica-carbon according to the following examples are prepared according to the following steps. Quantum dot composite:

[0025] Step 1, glucose 1 mmol, each amount is given an ethylenediamine, and 1 mmol of orthosilicate, and the raw material is added to 100% ethanol, and mixed, dissolved, dissolved, dissolved to form a uniform reaction solution;

[0026] Step 2, the resulting reaction solution is refluxed for 5 hours at 80 ° C;

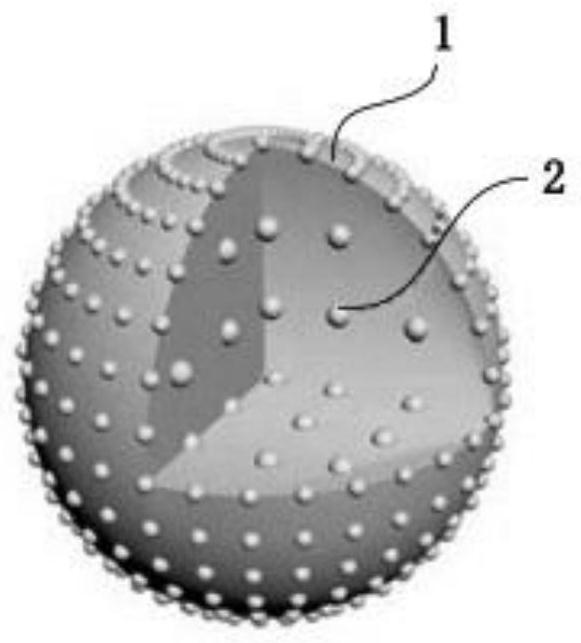

[0027] Step three, centrifuge, filtrate, the collected precipitate is a semi-finished product of a silica-carbon quantum dot composite, which includes a silica body 1 and a carbon quantum point 2 embedded in the silica main body 1, specifically like figure 1 As shown, the semi-finished product is sufficiently washed, dried;

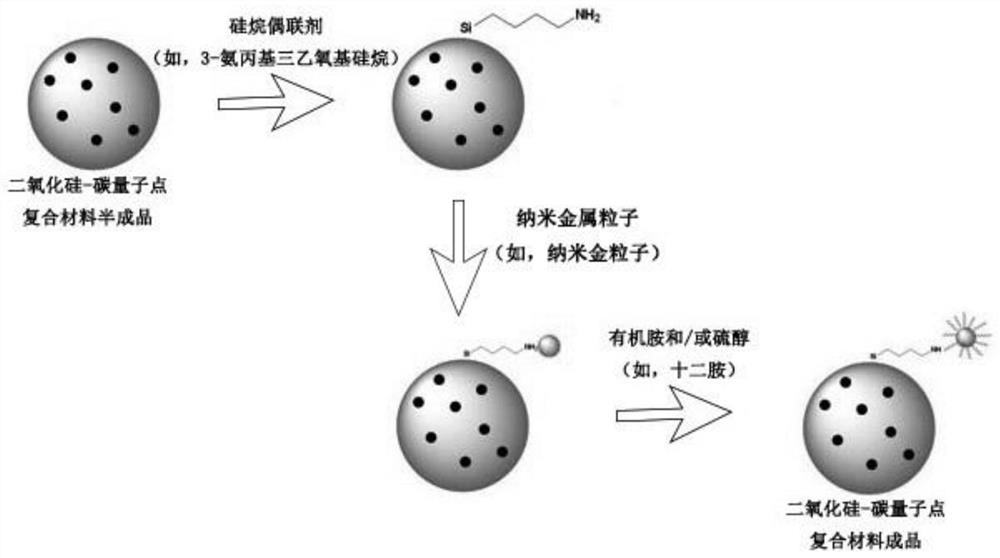

[0028] Step 4, the semi-finished product obtained by step ...

Embodiment 2

[0034] The experimental group is arranged, and glucose and ethylenediamine are used, ethyl orthosilicate is used as a raw material, and the silica-carbon quantum dot composite material is prepared according to the following steps:

[0035] Step 1, glucose 1 mmol, each amount is given an ethylenediamine, and 1 mmol of orthosilicate, and the raw material is added to 100% ethanol, and mixed, dissolved, dissolved, dissolved to form a uniform reaction solution;

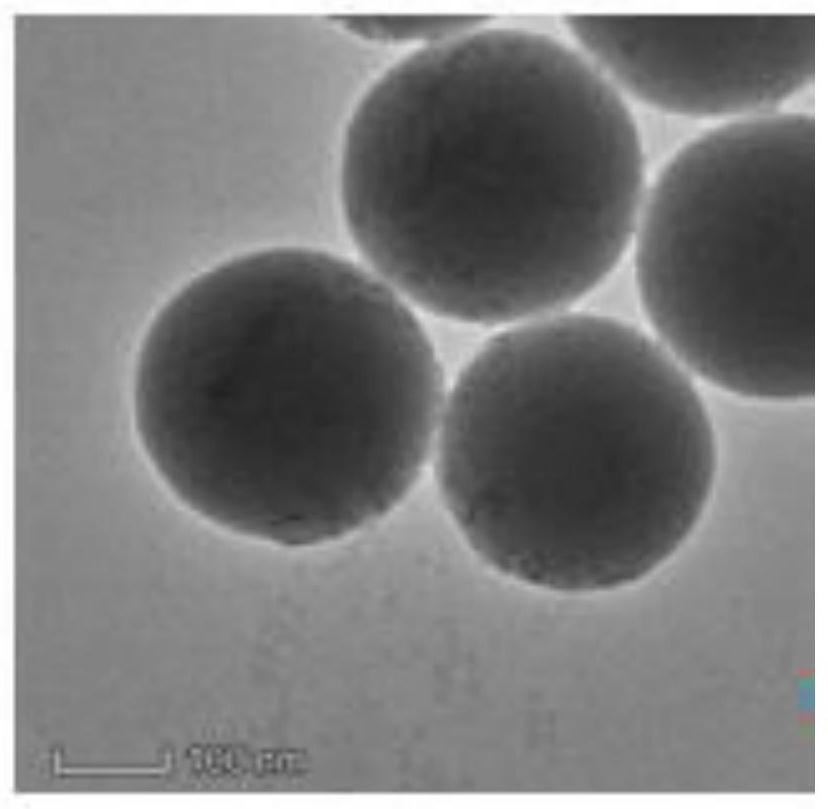

[0036] Step 2, the resulting reaction liquid is refluxed in 80 ° C for 5 hours, and the structure is formed in the reaction liquid. figure 1 The semi-finished product of the silica-carbon quantum dot composite, the semi-finished image observed under the scanning electron microscope, such asimage 3 Indicated.

[0037] The control group is arranged, and glucose and ethylenediamine are used as a raw material, and the carbon quantum dots are prepared according to the following steps:

[0038] Step 1, glucose 1 mmol, quantified 1 m...

Embodiment 3

[0044] 1, process group building mode

[0045] In this example, a method of preparing a silica-carbon quantum dot composite material provided in Example 1, as a silane coupling agent in step four in step four, as step six by dimethine The organic amine in which different nano metal particles is used as a raw material, and a silica-carbon quantum dot composite is prepared. According to the species of the nano metal particles employed, each treatment group is numbered, in particular: Treatment I, the nano metal particles employed are nano silver particles; treatment II, the nano metal particles employed are nano gold particles; treatment III The nano metal particles employed are nanoplasmic particles; treatment IV, the nano metal particles employed are nanopoly particles. Different experiments are adjusted by finite experiments in accordance with the type of nano metal particles employed to obtain a specific raw material feed ratio when the carbon quantum dot transceration rate is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com