Catalytic cracking auxiliary agent containing donut-shaped mesoporous material and preparation method and application thereof

A catalytic cracking aid and mesoporous material technology, applied in catalytic cracking, hydrocarbon cracking to hydrocarbon production, molecular sieve catalyst, etc. Low cost of raw materials and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] According to the present invention, the preparation method of the donut-shaped mesoporous material comprises:

[0033] (a) mixing the templating agent and N,N-dimethylformamide with an acidic aqueous solution to obtain a mixture;

[0034] (b) The mixture is contacted with a silicon source, and the obtained mixture is subjected to crystallization, washing, suction filtration, drying and template removal treatment to obtain a doughnut-shaped mesoporous material.

[0035] According to the present invention, the template is a three-block copolymer polyoxyethylene-polyoxypropylene-polyoxyethylene template, preferably P123.

[0036] Preferably, the acidic aqueous solution is an aqueous hydrochloric acid solution prepared from water and hydrogen chloride.

[0037] Preferably, the silicon source is selected from one or more of ethyl orthosilicate, methyl orthosilicate, propyl orthosilicate, sodium orthosilicate and silica sol, preferably ethyl orthosilicate.

[0038]Preferabl...

Embodiment 1

[0073] This embodiment is to illustrate the catalytic cracking aid containing donut-shaped mesoporous material prepared by the method of the present invention.

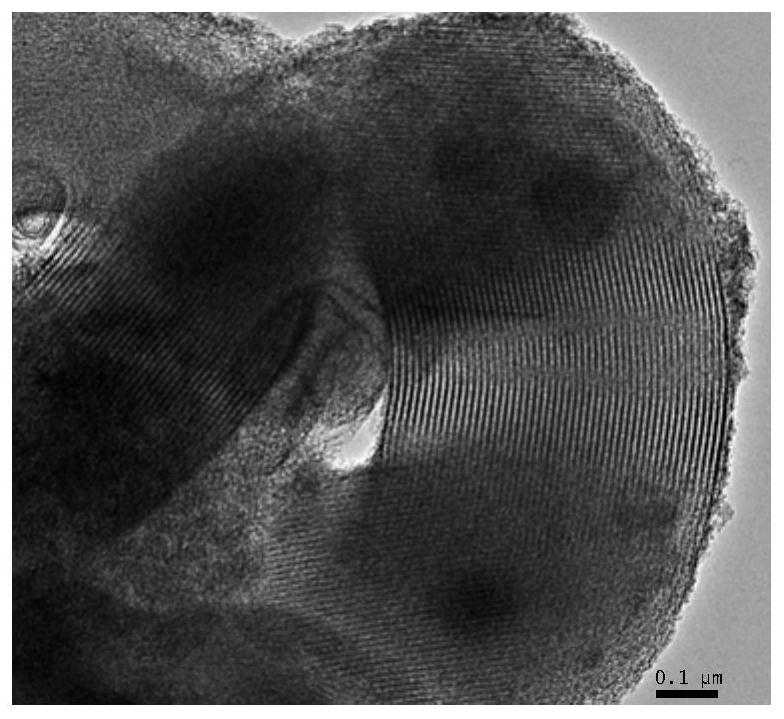

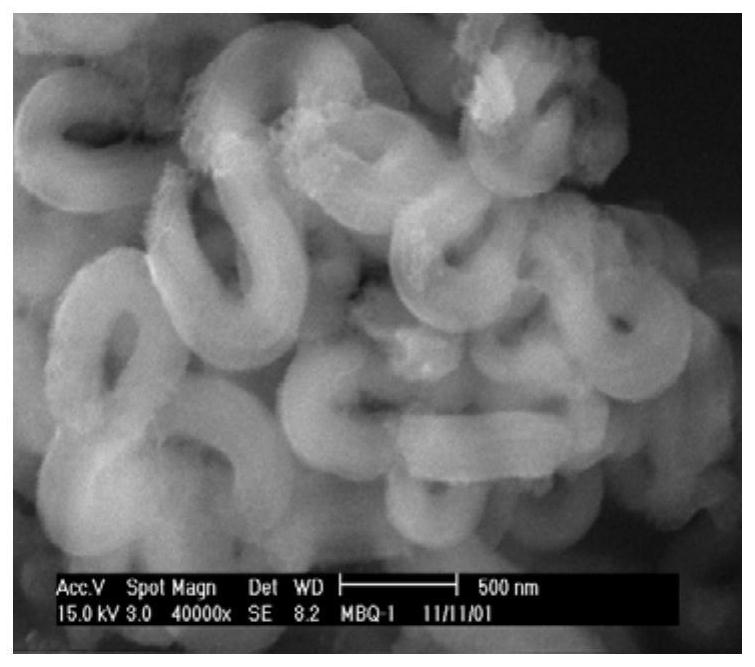

[0074] (1) Preparation of doughnut-shaped mesoporous materials

[0075] Mix 58g of P123 (0.01mol), 438g (6mol) of N,N-dimethylformamide with 2450g of hydrochloric acid aqueous solution (containing 3mol of HCl), and stir at 40°C until P123 is completely dissolved; 125g of ethyl orthosilicate (0.6 mol) was added to the above solution, and continued to stir at 40°C for 24h to crystallize; after the crystallization was completed, filter to obtain a solid substance; the solid substance was washed with deionized water 8 times, and then dried at 120°C for 10h to obtain the original powder of the mesoporous material; The raw powder of the mesoporous material was calcined at 500° C. for 20 h to remove the template agent, and a doughnut-shaped mesoporous material A was obtained.

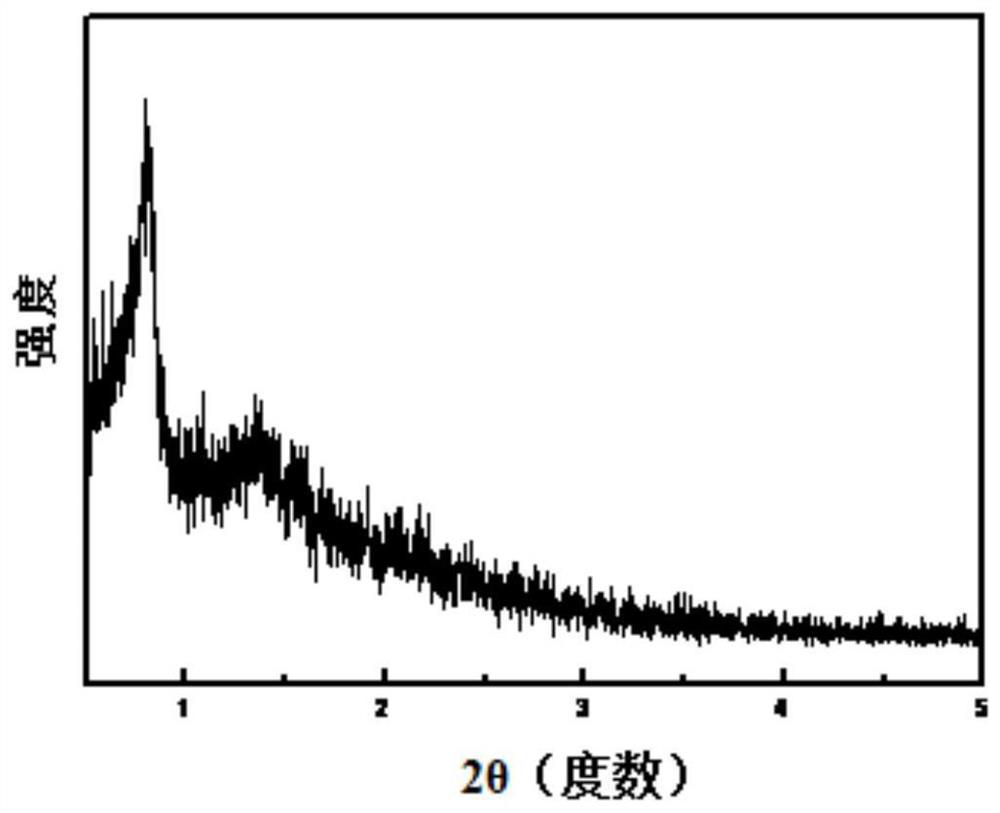

[0076] Donut-shaped mesoporous material A has ...

Embodiment 2

[0085] This embodiment is to illustrate the catalytic cracking aid containing donut-shaped mesoporous material prepared by the method of the present invention.

[0086] (1) Preparation of doughnut-shaped mesoporous materials

[0087] Mix 58g of P123 (0.01mol), 365g (5mol) of N,N-dimethylformamide and 1873g of aqueous hydrochloric acid (containing 2mol of HCl), and stir at 25°C until P123 is completely dissolved; 104g of ethyl orthosilicate (0.5mol) was added to the above solution, and continued to stir at 25°C for 40h to crystallize; after the crystallization was completed, the solid substance was obtained by filtration; the solid substance was washed with deionized water 8 times, and then dried at 150°C for 3h to obtain the original mesoporous material powder; the raw powder of the mesoporous material was calcined at 400° C. for 30 h to remove the template agent, and the donut-shaped mesoporous material B was obtained.

[0088] Donut-shaped mesoporous material B has a specif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap