Preparation method of lithium iron phosphate and product and application of lithium iron phosphate

A technology of lithium iron phosphate and phosphoric acid, applied in the field of new energy materials, can solve the problems of difficult control of synthesis conditions, difficult control of components, and high production costs, and achieve the effects of low cost, environmental friendliness, and reduced production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) 57.6 parts by weight of 85% phosphoric acid is added to 142.6 parts by weight of deionized water to prepare a phosphoric acid solution, add 37.5 parts by weight of natural magnetite powder under stirring, continue to stir, and mix well , to obtain a stable mixed solution, add it to a nano sand mill for ball milling, and obtain a black slurry with a particle size distribution D50 of about 400nm after ball milling. The material was taken out, and the obtained slurry was heated at 60 °C for 6 h, and then H 2 o 2 , until the black slurry is oxidized to white iron phosphate dihydrate slurry, and then the white slurry is spray-dried and placed in a muffle furnace for calcination at 600° C. for 8 hours to obtain a dry powder (anhydrous iron phosphate powder).

[0035] (2) Mix 150 parts of the dry powder obtained in step (1) with 38.8 parts of lithium carbonate and 15.8 parts of sucrose in deionized water and stir evenly, ball mill in a sand mill until D50 is below 200nm, ...

Embodiment 2

[0039] Same as Example 1, the difference is that the heating temperature of the black slurry in step 1 is 70°C.

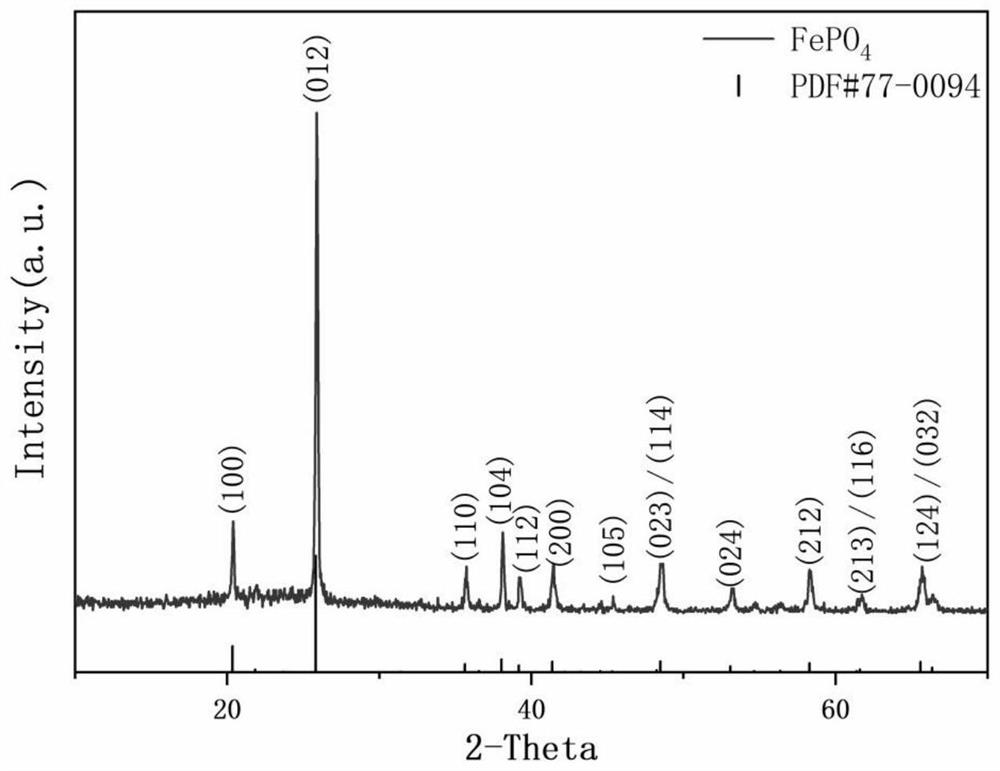

[0040] The anhydrous iron phosphate powder and lithium iron phosphate powder prepared in this embodiment were tested using an X-ray diffractometer, and the XRD detection results of the obtained results were consistent withfigure 1 and figure 2 similar. After refinement by software (EXPGUI), the diffraction spectrum can be confirmed to correspond to anhydrous iron phosphate (PDF#77-0094) and lithium iron phosphate (PDF#81-1173) respectively without obvious impurity peaks. The precursor anhydrous iron phosphate prepared by the method and the final product lithium iron phosphate are pure phase substances.

[0041] Gained lithium iron phosphate battery material is carried out scanning electron microscope (SEM, Japan Electronics 6700F) test, the SEM observation result of gained is consistent with image 3 Similarly, the obtained carbon-coated lithium iron phosphate c...

Embodiment 3

[0043] Same as Example 1, the difference is that the heating temperature of the black slurry in step 1 is 80°C.

[0044] The anhydrous iron phosphate powder and lithium iron phosphate powder prepared in this embodiment were tested using an X-ray diffractometer, and the XRD detection results of the obtained results were consistent with figure 1 and figure 2 similar. After refinement by software (EXPGUI), the diffraction spectrum can be confirmed to correspond to anhydrous iron phosphate (PDF#77-0094) and lithium iron phosphate (PDF#81-1173) respectively without obvious impurity peaks. The precursor anhydrous iron phosphate prepared by the method and the final product lithium iron phosphate are pure phase substances.

[0045] Gained lithium iron phosphate battery material is carried out scanning electron microscope (SEM, Japan Electronics 6700F) test, the SEM observation result of gained is consistent with image 3 Similarly, the obtained carbon-coated lithium iron phosphate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com