Asphalt polyurethane waterproof coating and preparation method thereof

A polyurethane waterproof and waterproof coating technology, used in polyurea/polyurethane coatings, asphalt coatings, coatings, etc., can solve the problems of easy adverse reactions, high surface energy, poor adhesion, etc., to improve compatibility and Adhesion, low surface energy, strong bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The second aspect of the embodiment of the present application provides a method for preparing an asphalt polyurethane waterproof coating, comprising steps:

[0051] S01. Stir and mix polyether polyol, polyolefin polyol, asphalt, plasticizer, defoamer and filler to obtain a first mixture;

[0052] S02. Under the condition that the relative vacuum degree is -0.08MPa~-0.1MPa, the first mixture is stirred and heated to 100°C-110°C, and dehydrated for 2h-3h to obtain the second mixture;

[0053] S03. Add diisocyanate, latent curing agent and catalyst to the second mixture to react for a preset time to obtain bituminous polyurethane waterproof coating.

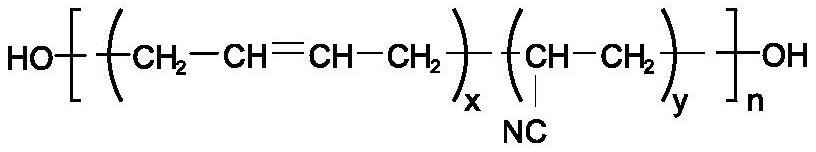

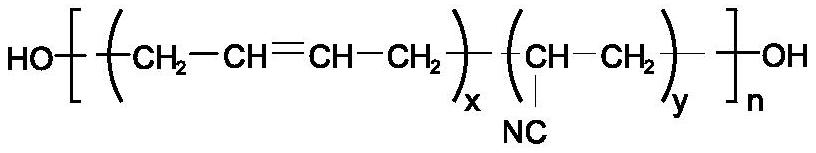

[0054] In step S01, the polyether polyol, hydroxyl-terminated polybutadiene acrylonitrile, asphalt, filler and plasticizer can be dispersed for 4 minutes to 6 minutes at a rotation speed of 800 rpm to 1200 rpm; then the rotation speed is adjusted to 1500 rpm to 2000 rpm to further Disperse for 30 minutes to 50 minutes to ob...

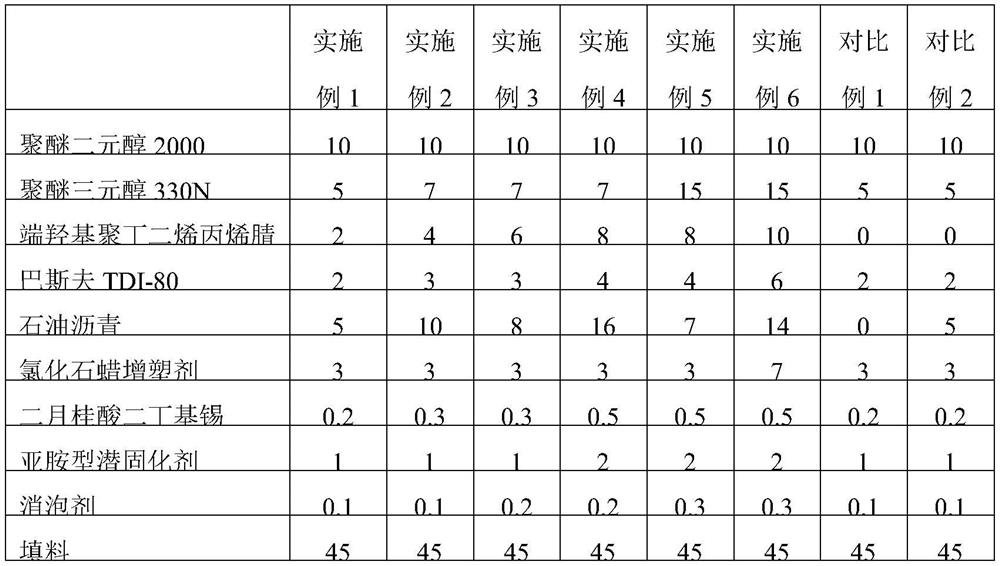

Embodiment 1

[0065] A kind of asphalt polyurethane waterproof coating, raw material comprises by weight: polyether glycol 2000, 10 parts; polyether trihydric alcohol 330N, 5 parts; Acrylonitrile, 2 parts; BASF TDI-80, 2 parts; Chlorinated paraffin, 3 parts; No. 70 petroleum pitch, 5 parts; Dibutyltin dilaurate, 0.2 parts; Foaming agent, 0.1 part; 1250 mesh talcum powder, 20 parts; 800 mesh heavy calcium, 25 parts.

Embodiment 2

[0067] A kind of asphalt polyurethane waterproof coating, raw material comprises by weight: polyether glycol 2000, 10 parts; polyether trihydric alcohol 330N, 7 parts; Acrylonitrile, 4 parts; BASF TDI-80, 3 parts; chlorinated paraffin, 3 parts; No. 70 petroleum pitch, 10 parts; dibutyltin dilaurate, 0.3 parts; imine latent curing agent, 1 part; Foaming agent, 0.1 part; 1250 mesh talcum powder, 20 parts; 800 mesh heavy calcium, 25 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com