Cubic MOF-5 catalyst and preparation method and application thereof in production of hydrogen peroxide through oxygen reduction

A technology of MOF-5 and catalyst, applied in electrolysis components, electrodes, electrolysis process, etc., can solve problems such as reaction failure, and achieve the effects of convenient operation, simple preparation process and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A preparation method of cubic MOF-5 catalyst, comprising the following steps:

[0039] 1) Zn(OAc) 2 2H 2 O was dissolved in NMP to prepare Zn(OAc) 2 2H 2 O concentration is the zinc salt solution of 160mM; Dissolving terephthalic acid in NMP, preparation concentration is the terephthalic acid solution of 80mM;

[0040] 2) Add PVP to the terephthalic acid solution prepared in step 1), and ultrasonically dissolve to obtain solution A, the concentration of PVP in solution A is 200mM. The solution A is mixed with the zinc salt solution prepared in step 1) according to a volume ratio of 2:1, so that the reaction raw material Zn(OAc) 2 2H 2 The molar feed ratio of O and terephthalic acid is 1:1;

[0041] 3) The mixed solution obtained in step 2) was transferred to a high-temperature-resistant glass reaction tube, sealed and transferred to a microwave heating device, and the microwave heating reaction was started. The microwave power was 50W, the reaction temperature was...

Embodiment 2

[0044] A preparation method of a cubic MOF-5 catalyst, the preparation method repeats Example 1, the difference is only in "step 2), solution A and zinc salt solution are mixed in equal volume, so that the reaction raw material Zn(OAc) 2 2H 2 The molar feed ratio of O and terephthalic acid is 2:1", and the remaining steps are repeated in Example 1, and the final catalyst is marked as MOF-5-2.

Embodiment 3

[0046] A preparation method of a cubic MOF-5 catalyst, the preparation method repeats Example 1, the difference is only in "step 2), solution A and zinc salt solution are mixed according to the volume ratio of 1:1.5, so that the reaction Raw material Zn(OAc) 2 2H 2 The molar ratio of O to terephthalic acid is 3:1", and the remaining steps are repeated in Example 1, and the final catalyst is marked as MOF-5-3.

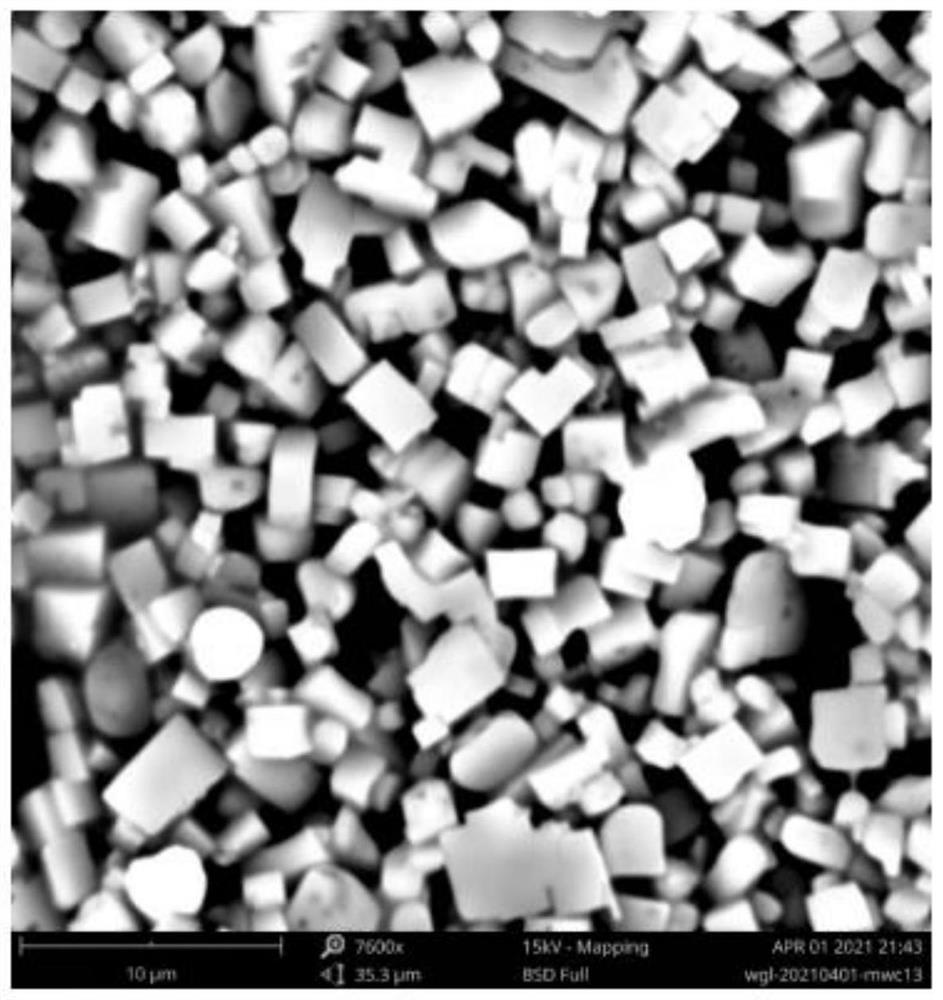

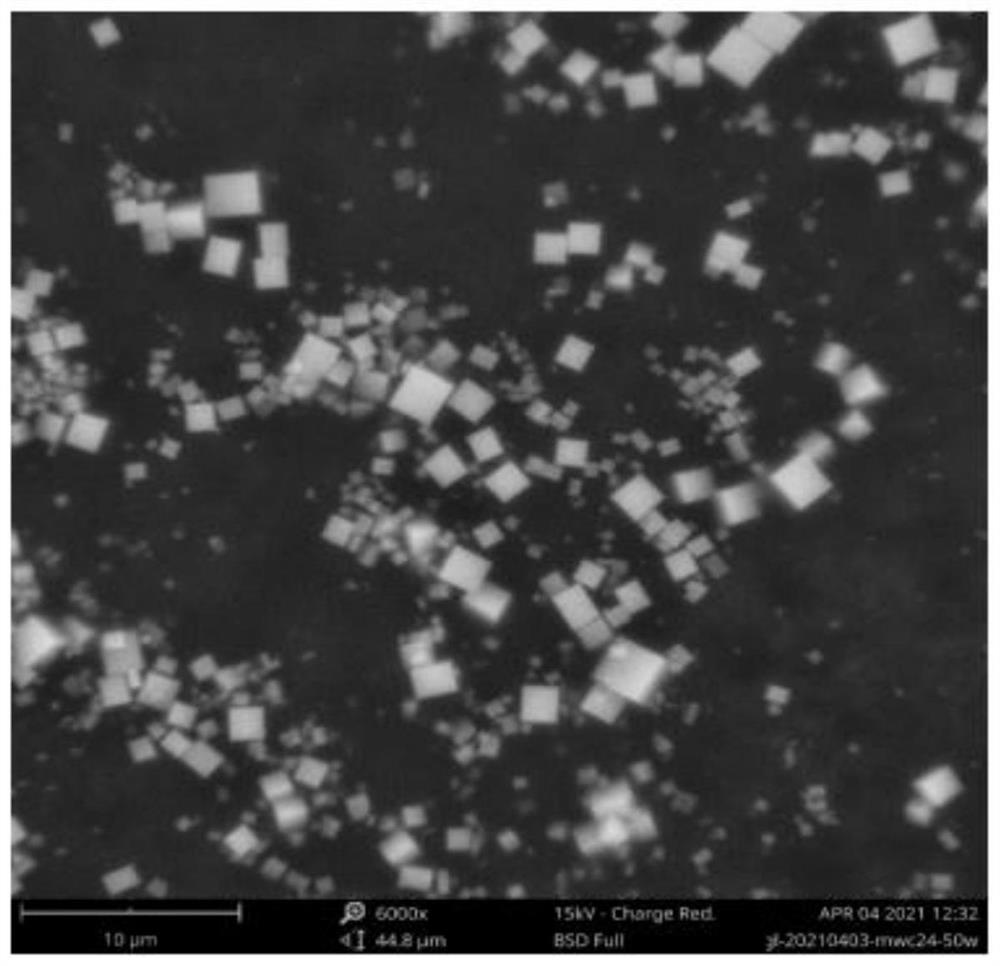

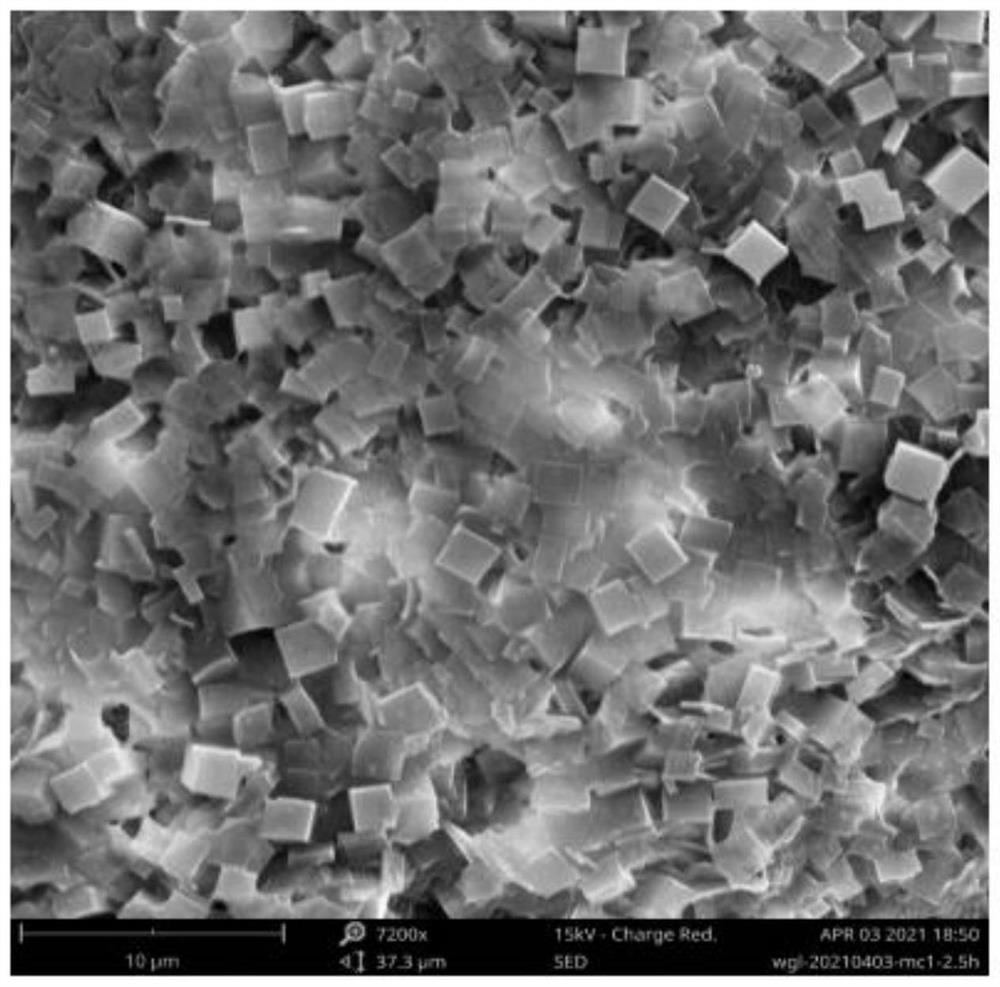

[0047] The catalysts MOF-5-1, MOF-5-2, and MOF-5-3 prepared in the above examples 1-3 were respectively subjected to SEM characterization, and the SEM characterization results were as follows: figure 1 , figure 2 with image 3 shown. from Figure 1-3 By comparison, it can be seen that the reaction raw material Zn(OAc) 2 2H 2 When the molar ratio of O to terephthalic acid is 1:1 (corresponding figure 1 ), the reaction generates irregular crystals such as spheres or columns; the reaction raw material Zn(OAc) 2 2H 2 When the molar ratio of O to terephthalic acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com