Laser irradiation PbS quantum dot embedded SnSe thermoelectric material and preparation method and application thereof

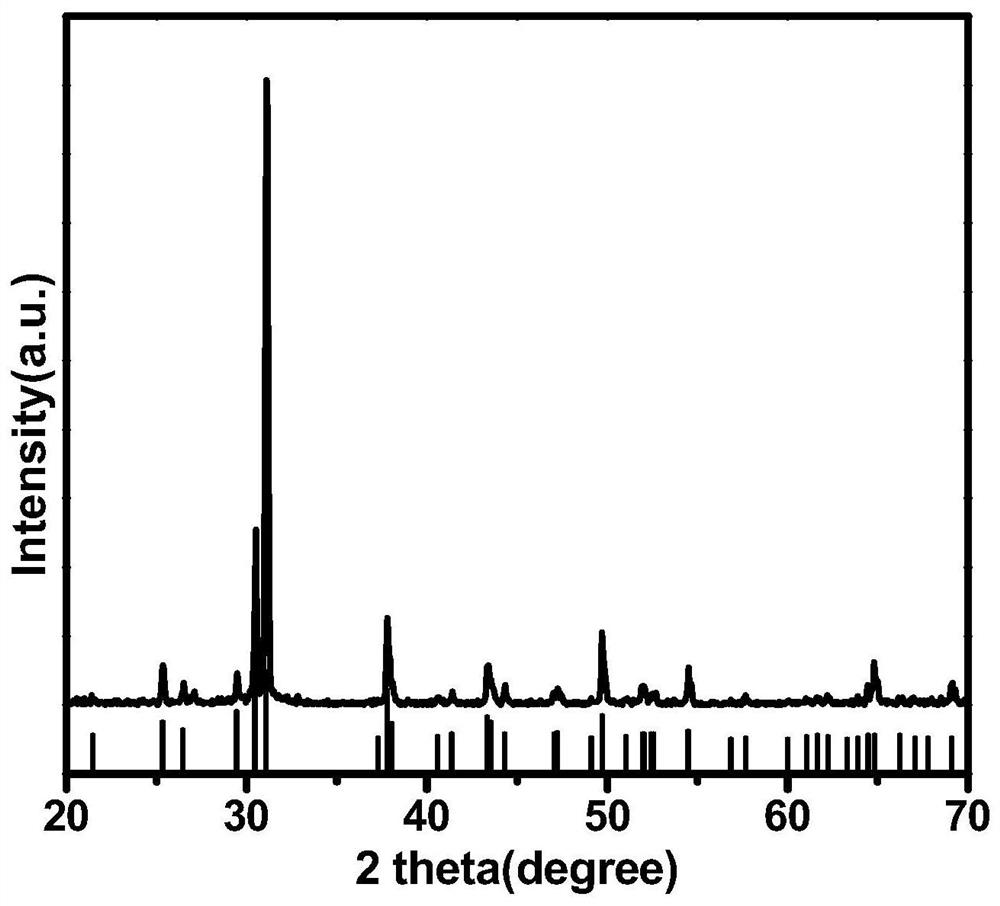

A laser irradiation, thermoelectric material technology, applied in the direction of thermoelectric device junction lead-out material, thermoelectric device manufacturing/processing, etc. The effect of improving Seebeck coefficient, improving electrical conductivity, and strong crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

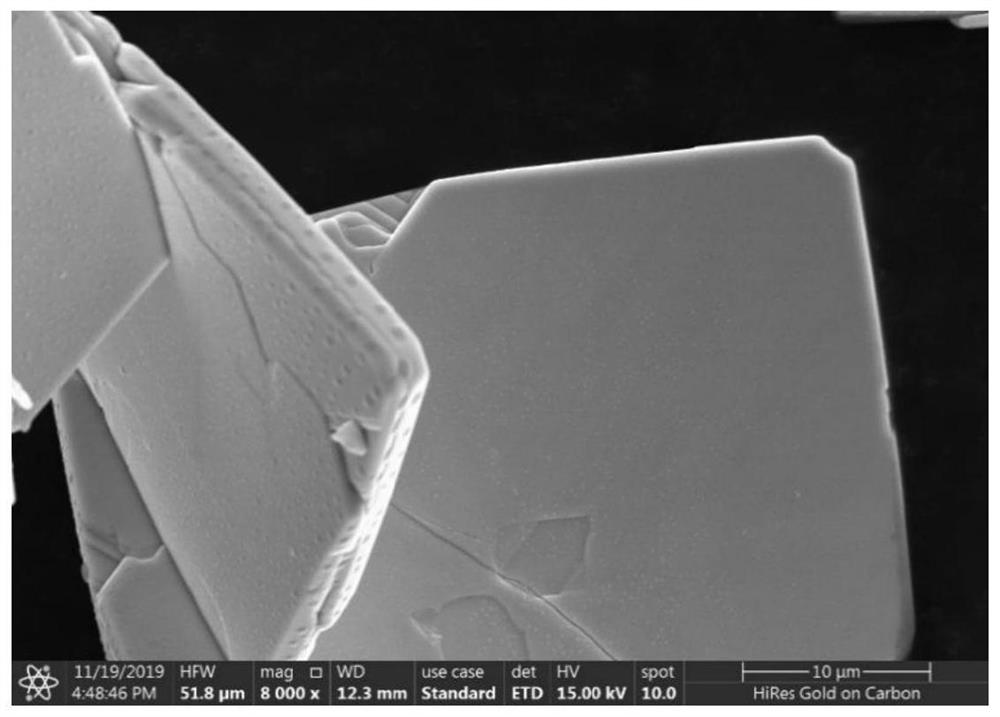

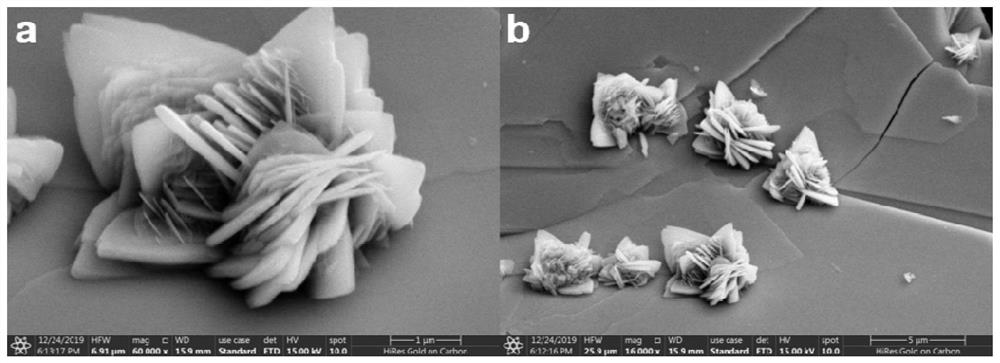

[0030] The invention provides a preparation method for laser irradiation of PbS quantum dots embedded in SnSe thermoelectric materials, comprising the following steps:

[0031] Step 1, mixing 0.1-0.3g of PbS and 10mL of ethylene glycol to obtain solution A;

[0032] Step 2, irradiating solution A with a non-focused laser for 5 to 15 minutes in ultrasound, with a laser frequency of 10 Hz, a wavelength of 1064 nm, and a power of 300 to 800 mJ, to obtain solution B;

[0033] Step 3, the SnCl of 0.5~2.5g 2 2H 2 The ethylene glycol of O and 40mL is mixed, obtains solution C;

[0034] Step 4, the NaSeO of 1.0~2.0g 3 Mix with solution C to obtain solution D;

[0035] Step 5, mixing solution B and solution D to obtain solution E;

[0036] Step 6, mixing 3-5g of NaOH with solution E to obtain solution F;

[0037] Step 7, put the solution F in the reaction kettle, and carry out the solvothermal reaction at 200-230°C for 24-36h; the product system after the reaction is washed three...

Embodiment 1

[0042] (1) Mix 0.1g of PbS and 10mL of ethylene glycol to obtain solution A;

[0043] (2) The solution A was irradiated by a non-focused laser in ultrasound for 5 minutes, the frequency of the laser was 10 Hz, the wavelength was 1064 nm, and the power was 300 mJ to obtain a solution B;

[0044] (3) 1.7g of SnCl 2 2H 2 The ethylene glycol of O and 40mL is mixed, obtains solution C;

[0045] (4) 1.3g of NaSeO 3 Mix with solution C to obtain solution D;

[0046] (5) Mix solution B and solution D to obtain solution E;

[0047] (6) 3g of NaOH is mixed with solution E to obtain solution F;

[0048] (7) Put the solution F in the reaction kettle, and carry out solvothermal reaction at 200°C for 24 hours; the product system after the reaction was washed with deionized water and ethanol three times, and then vacuum-dried at 80°C to obtain a solid product;

[0049] (8) The solid product obtained in step 7 was pressed by spark plasma sintering for 5 minutes at a pressure of 50 MPa t...

Embodiment 2

[0052] (1) Mix 0.1g of PbS and 10mL of ethylene glycol to obtain solution A;

[0053] (2) The solution A was irradiated by a non-focused laser in ultrasound for 5 minutes, the frequency of the laser was 10 Hz, the wavelength was 1064 nm, and the power was 400 mJ to obtain a solution B;

[0054] (3) 1.8g of SnCl 2 2H 2 The ethylene glycol of O and 40mL is mixed, obtains solution C;

[0055] (4) 1.4g of NaSeO 3 Mix with solution C to obtain solution D;

[0056] (5) Mix solution B and solution D to obtain solution E;

[0057] (6) 3.5g of NaOH is mixed with solution E to obtain solution F;

[0058] (7) Put the solution F in the reaction kettle, and carry out solvothermal reaction at 200°C for 24 hours; the product system after the reaction was washed with deionized water and ethanol three times, and then vacuum-dried at 80°C to obtain a solid product;

[0059] (8) The solid product obtained in step 7 was pressed by spark plasma sintering for 7 minutes at a pressure of 50 MPa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com