Hollow core-shell structure Fe3O4@SiO2@PANI wave-absorbing agent and preparation method

A technology of core-shell structure and wave absorbing agent, which is applied in the field of hollow core-shell structure Fe3O4@SiO2@PANI wave absorbing agent and preparation, which can solve the problems of poor stability, high density, and easy corrosion of conductive polymer materials, and achieve hollow core Clear shell structure, reduced experimental steps, and controllable experimental conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

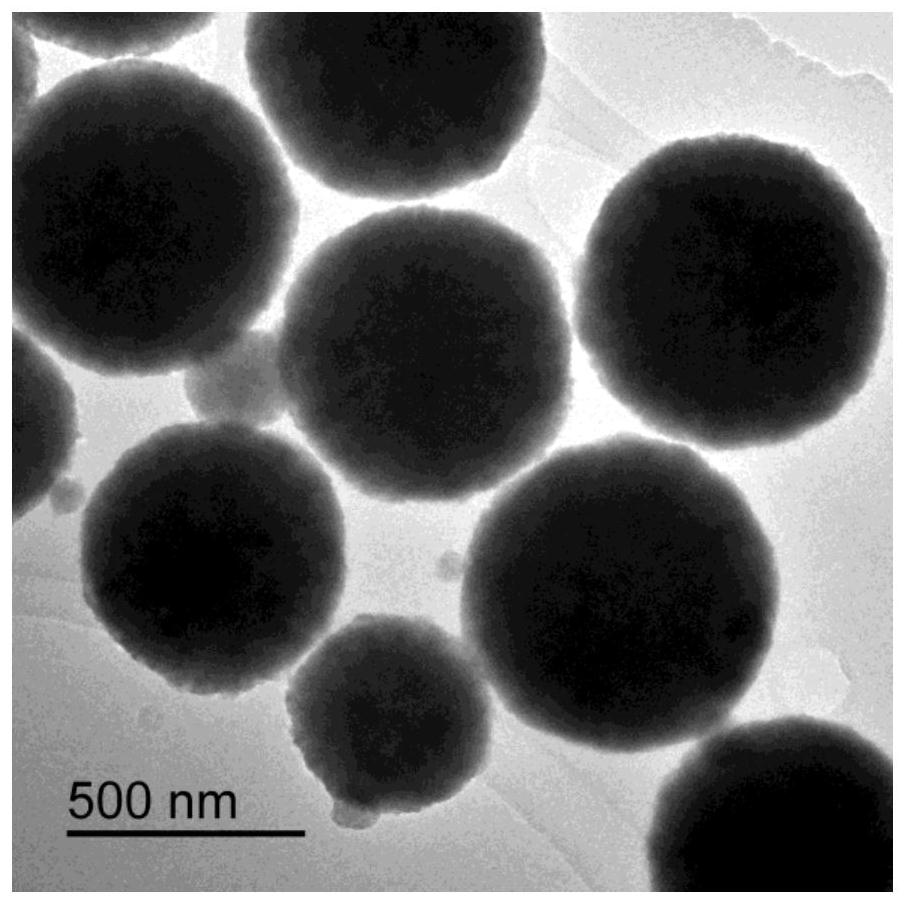

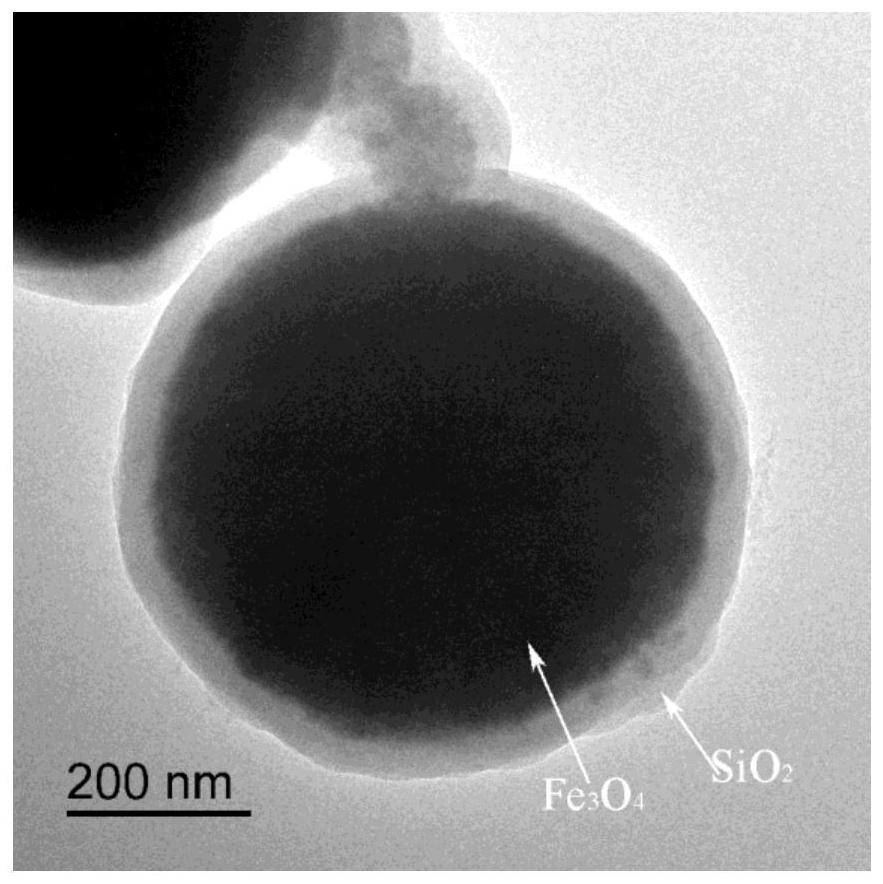

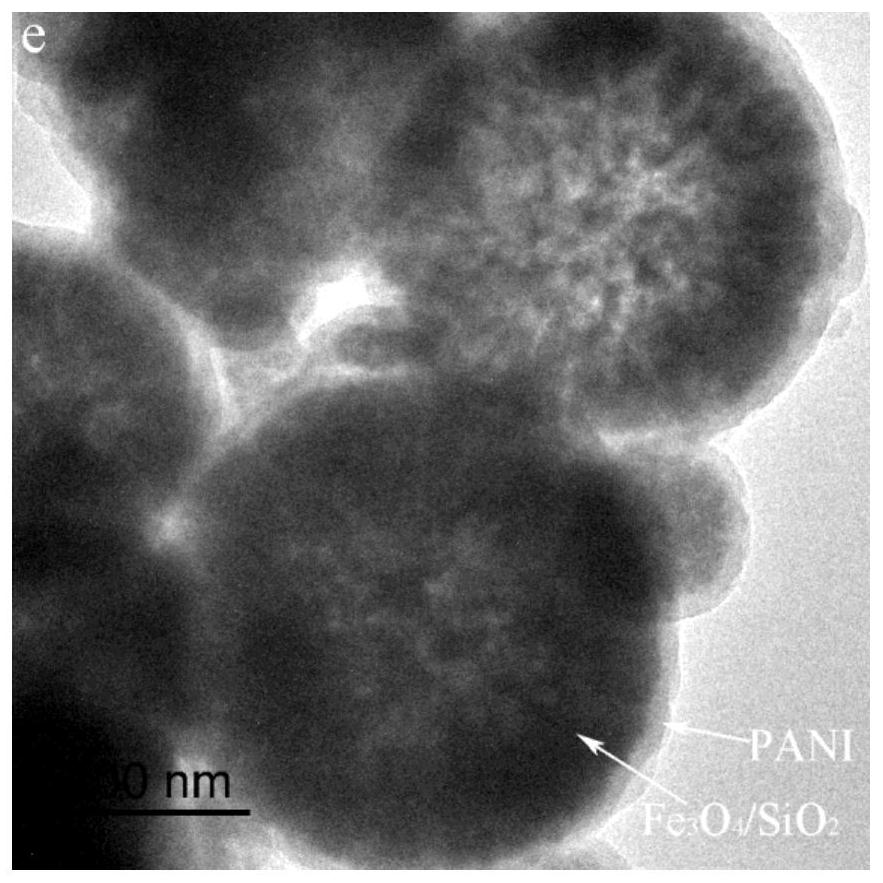

[0023] The invention provides a hollow core-shell structure Fe 3 o 4 @SiO 2 The preparation method of @PANI wave absorbing agent, comprises the following steps:

[0024] Step 1: Fe 3 o 4 Preparation of nanospheres: FeCl 3 ·6H 2 O was dissolved in 40 mL of ethylene glycol, and CH was added 3 COONa and 1.0000g polyethylene glycol 2000, where FeCl 3 ·6H 2 O and CH 3 The molar ratio of COONa is 1:5~6. After mixing evenly, adopt a one-step hydrothermal method to react at 200°C for 8 hours, separate the product by magnetic separation, wash with water and alcohol for many times, and obtain a magnetic black powder after vacuum drying. 3 o 4 nanospheres.

[0025] Step 2: Fe 3 o 4 Activation of nanospheres: the Fe obtained in the above step 1 3 o 4 The molar ratio of nanospheres and PVP is 1:1~2, dispersed in deionized water and stirred evenly, and then the product is separated by magnetic separation, and the obtained activated Fe 3 o 4 The nanospheres were washed repea...

Embodiment 1

[0030] Step 1: Add 1.3500g FeCl 3 ·6H 2 O was dissolved in 40 mL of ethylene glycol, and 3.6000 g of CH was added 3 COONa·3H 2 O and 1.0000g polyethylene glycol 2000, mixed evenly, reacted at 200°C for 8 hours by one-step hydrothermal method, separated the product by magnetic separation, washed with water and alcohol for many times, and obtained a magnetic black powder after vacuum drying, namely Fe3O4 nanospheres.

[0031] Step 2: the 0.5gFe obtained in the above step 1 3 o 4 Nanospheres and 1gPVP were dispersed in 200mL deionized water and stirred evenly, and then the product was separated by magnetic separation, and the obtained activated Fe 3 o 4 The nanospheres were washed repeatedly with deionized water and absolute ethanol, and dried at 60 °C for 24 h.

[0032] Step 3: First prepare a mixed solution of 80mL of absolute ethanol, 20mL of deionized water and 2mL of ammonia water, and then add 0.2g of activated Fe 3 o 4 The nanospheres were dispersed in the above m...

Embodiment 2

[0036] Step 1: Add 1.3500g FeCl 3 ·6H 2 O was dissolved in 40 mL of ethylene glycol, and 3.6000 g of CH was added 3 COONa·3H 2 O and 1.0000g polyethylene glycol 2000, after mixing evenly, adopt one-step hydrothermal method to react at 200°C for 8 hours, separate the product by magnetic separation, wash with water and alcohol for many times, and obtain a magnetic black powder after vacuum drying. 3 o 4 nanospheres.

[0037] Step 2: the 0.5gFe obtained in the above step 1 3 o 4 Nanospheres and 1gPVP were dispersed in 200mL deionized water and stirred evenly, and then the product was separated by magnetic separation, and the obtained activated Fe 3 o 4 The nanospheres were washed repeatedly with deionized water and absolute ethanol, and dried at 60 °C for 24 h.

[0038] Step 3: First prepare a mixed solution of 80mL of absolute ethanol, 20mL of deionized water and 2mL of ammonia water, and then add 0.2g of activated Fe 3 o 4 The nanospheres were dispersed in the above m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com