Preparation method of nano cobalt hexacyanocobaltate/nitrogen-doped porous carbon composite material

A technology of nitrogen-doped porous carbon and composite materials, which is applied in the field of synthesis of electrode materials for energy storage devices, can solve the problems of poor material binding ability, poor wettability of carbon materials, cumbersome process, etc., and achieve improved reaction rate, excellent performance, and resources. rich effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

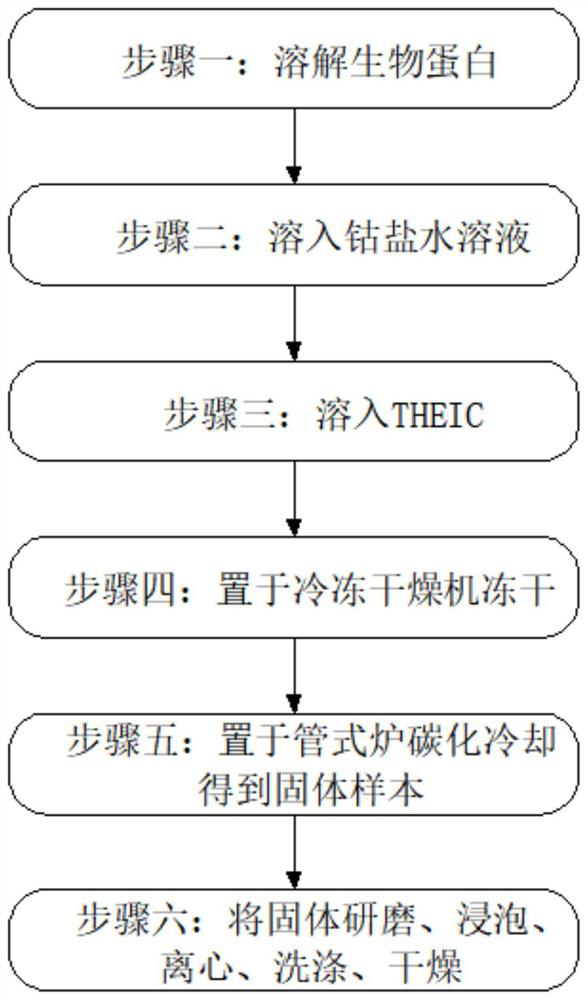

[0034] A kind of synthetic method of nano cobalt hexacyanocobaltate / nitrogen-doped porous carbon composite material, the steps are as follows:

[0035] R(1): Put 60mL of 1.0mol / L NaOH solution into a 100mL beaker, add 3g of casein while heating with magnetic stirring, keep the temperature at 45°C, and stir until it is completely dissolved;

[0036] R(2): Under the condition of magnetic stirring and keeping the temperature at 45°C, use a dropper to draw 10mL of the prepared 70mmol / L Co(NO3)2 solution and add it dropwise to the solution obtained in step R(1), and continue to stir until The solution is uniform;

[0037] R(3): Add 0.3g THEIC to the mixed solution in R(2), and dissolve to a uniform state (no precipitate) under magnetic stirring;

[0038] R(4): Then put the mixed solution in a homogeneous state into a vacuum freeze dryer, and freeze-dry at -82°C for 30 hours;

[0039] R(5): Put the mixture powder obtained after freeze-drying into a vacuum tube furnace, heat to 650°C...

Embodiment 2

[0042] A kind of synthetic method of nano cobalt hexacyanocobaltate / nitrogen-doped porous carbon composite material, the steps are as follows:

[0043] S(1): Put 60mL of 0.8mol / L KOH solution into a 100mL beaker, add 3g of soybean protein while heating with magnetic stirring, keep the temperature at 40°C, and stir until it is completely dissolved;

[0044] S(2): Under the condition of magnetic stirring and keeping the temperature at 40°C, pipette 15mL of the prepared 50mmol / L CoCl2 solution into the solution obtained in step S(1) dropwise, and keep stirring until the solution is uniform;

[0045] S(3): Add 0.4g THEIC to the mixed solution in S(2), and dissolve to a uniform state (no precipitate) under magnetic stirring;

[0046] S(4): Then put the mixed solution in a homogeneous state into a vacuum freeze dryer, and freeze-dry at -55°C for 48 hours;

[0047] S(5): Put the mixture powder obtained after freeze-drying into a vacuum tube furnace, heat to 600°C and keep it warm fo...

Embodiment 3

[0050] A kind of synthetic method of nano cobalt hexacyanocobaltate / nitrogen-doped porous carbon composite material, the steps are as follows:

[0051] T(1): Take 50mL of 1.0mol / L NaOH solution into a 100mL beaker, add 4g of soybean protein while heating with magnetic stirring, keep the temperature at 50°C, and stir until it is completely dissolved;

[0052] T(2): Under the condition of magnetic stirring and the temperature is kept at 50°C, use a dropper to absorb 15mL of the prepared 50mmol / L CoC2O2 solution and add it dropwise to the solution obtained in step T(1), and continue to stir until the solution is uniform;

[0053] T(3): Add 0.6g THEIC to the mixed solution in T(2), and dissolve it to a uniform state (no precipitate) under magnetic stirring;

[0054] T(4): Then put the mixed solution in a homogeneous state into a vacuum freeze dryer, and freeze-dry at -80°C for 48 hours;

[0055] T(5): Put the mixture powder obtained after freeze-drying into a vacuum tube furnace,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com