Magnetic ferrite nanocrystal as well as preparation method and application thereof

A magnetic ferrite and nanocrystal technology, applied in the fields of magnetic objects, inductor/transformer/magnet manufacturing, magnetic materials, etc., can solve the problem of low biocompatibility, improve water solubility, high clinical translation significance, reduce effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] S1: Add 25ml of dibenzyl ether, 3ml of oleic acid and 1ml of oleylamine into a 50ml three-necked flask, continuously feed nitrogen to remove the oxygen in the system, add 2.2mmol of iron acetylacetonate and 0.8mmol of acetylacetonate respectively Manganese and 0.5mmol of zinc acetylacetonate are heated to 110°C by a program temperature control device, and the cap of the three-necked bottle is opened to remove water vapor in the solution, and then the cap is closed to make the acetylacetone complex, oleic acid and oleylamine completely React and maintain the temperature at 110°C for 1h;

[0035] S2: Next, continue to heat the S1 system to 220°C and maintain it for 2 hours, and observe that the solution changes from brownish red to bright black;

[0036] S3: Continue to raise the temperature of the S2 system to 300°C and maintain it for 1 hour;

[0037] S4: After the high-temperature reaction in step S3 is completed, remove the heat source at the bottom, transfer it to a...

Embodiment 2

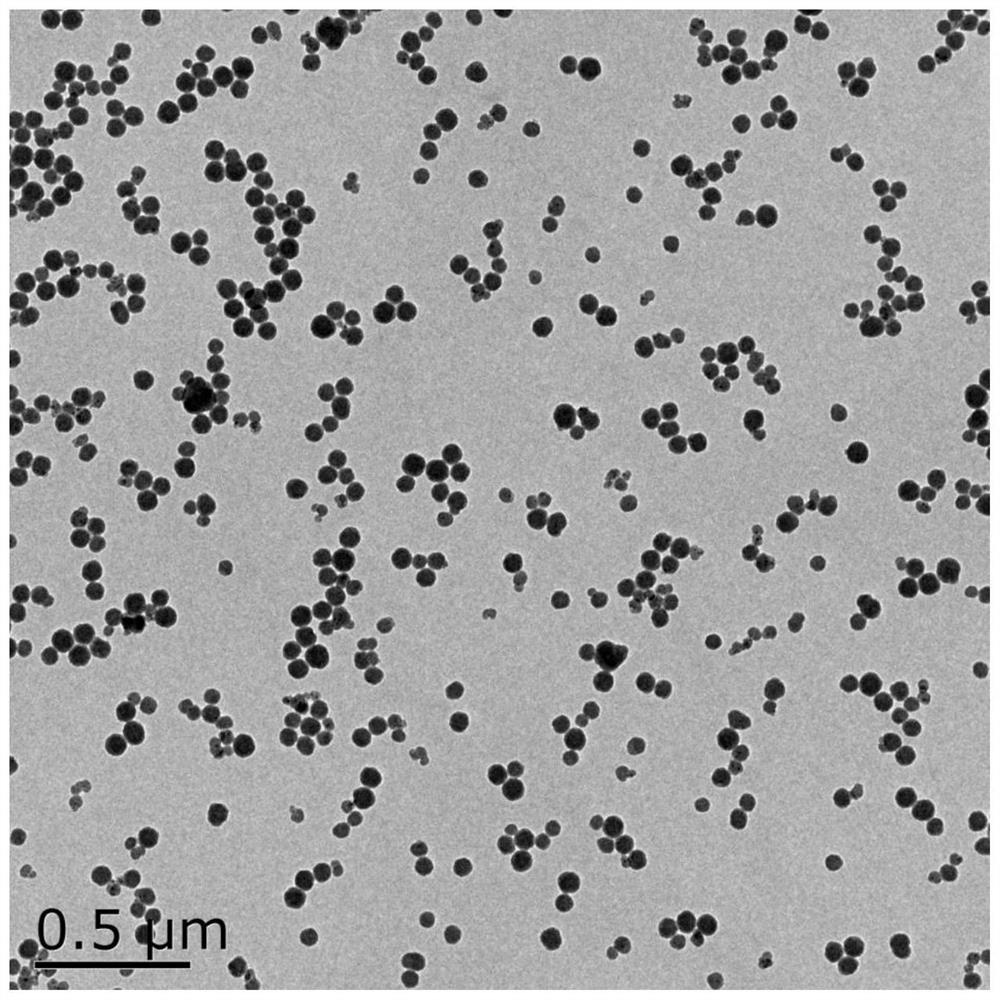

[0043] Change the temperature in step S1 in Example 1 to 105°C, change the temperature in step S2 to 200°C, change the heating time to 2.5h, change the temperature in step S3 to 310°C, and change the heating time to 1.5h . Other conditions remain unchanged, the obtained Fe3O4@SM was scanned by electron microscope and found that the obtained Fe 3 o 4 @SM is uniform in size and approximately spherical in shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com