DTRO discharged garbage permeation accumulation liquid advanced treatment method

A technology for advanced treatment and landfill leachate, applied in the direction of contaminated groundwater/leachate treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the complex composition of leachate, the decline of biodegradability, and the restriction of biochemical processes, etc. problem, to achieve the effect of reducing CODCr and ammonia nitrogen, improving biodegradability, and denitrification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

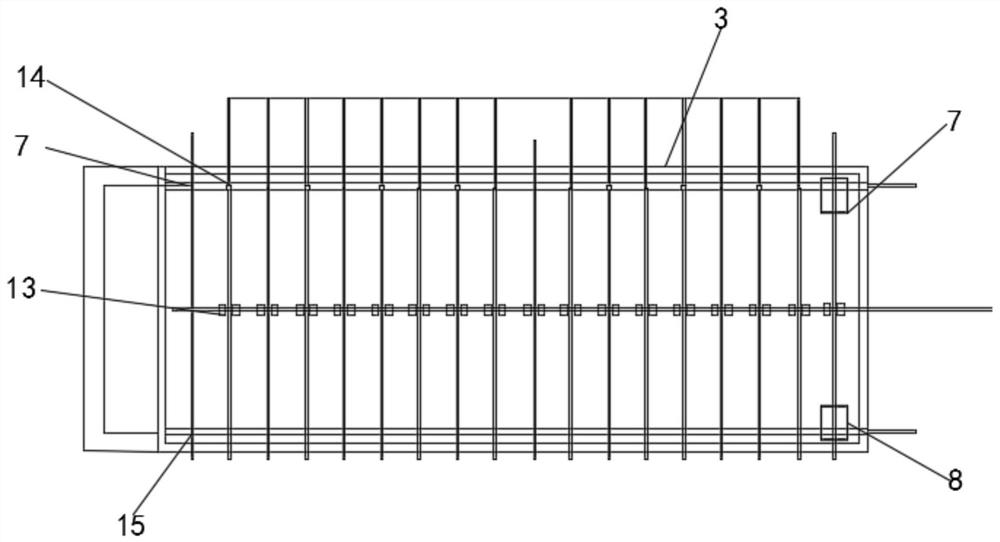

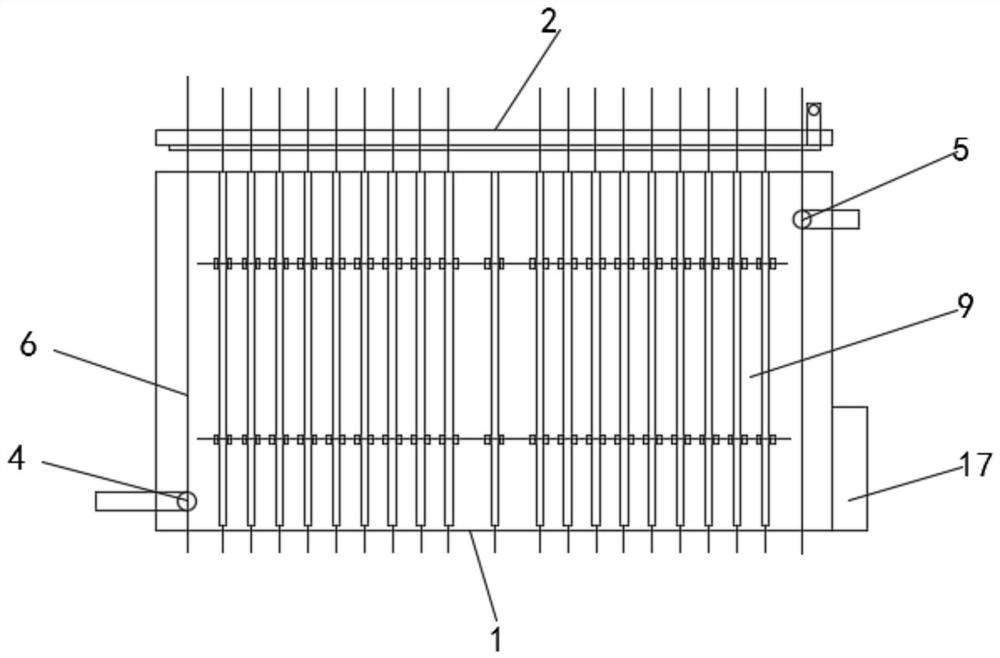

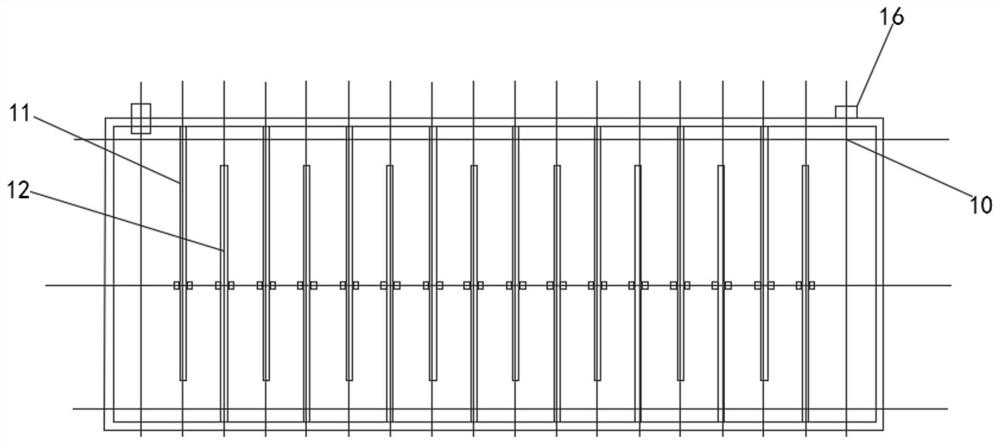

Image

Examples

Embodiment 1

[0030] Take the leachate from a composting plant, the water quality is CODCr25000~28000mg / l, ammonia nitrogen 1000~1200mg / l;

[0031] Add the leachate into the three-dimensional catalytic reactor (TCR), and after 2 hours of treatment, the concentrations of CODCr and ammonia nitrogen in the effluent are 1500-1800 mg / l and 300-350 mg / l, respectively;

[0032] The effluent from the three-dimensional catalytic reactor enters the anoxic / aerobic SBR reaction tank for biochemical treatment, relying on aerobic microorganisms in the reaction tank to degrade organic matter, and relying on aerobic nitrifying bacteria and anaerobic denitrifying bacteria to convert ammonia nitrogen into nitrogen. The operation cycle is 20 hours, divided into water intake for 1 hour, initial aeration for 6 hours, static stirring for 4 hours, secondary aeration for 6 hours, and sedimentation and drainage for 3 hours. The sludge load in the reactor is controlled at 0.3-0.8kg / (kg*d), the dissolved oxygen in th...

Embodiment 2

[0039] Take the leachate from an urban waste landfill that has been in operation for 5 years. The water quality is CODCr 15000-25000mg / l, ammonia nitrogen 1000-1200mg / l, and pH 6-8;

[0040] Put the leachate into the three-dimensional catalytic reactor and treat it for 2 hours. The concentrations of CODCr and ammonia nitrogen in the effluent are 1000-1700mg / l and 250-300mg / l respectively;

[0041] The effluent from the three-dimensional catalytic reactor enters the anoxic / aerobic SBR reaction tank for biodegradation of organic matter and nitrification and denitrification biological denitrification treatment. The operation cycle is 20 hours, divided into water intake for 2 hours, initial aeration for 6 hours, and static stirring for 5 hours. Then aerate for 4 hours, sedimentation and drainage for 3 hours, the sludge load in the reactor is controlled at 0.3-0.8kg / (kg*d), the dissolved oxygen in the water during the aeration stage is controlled at 0.5-4mg / l, after SBR biochemical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com