Preparation method of integrated high-performance electrode for solid-state battery

A solid-state battery, high-performance technology, applied in battery electrodes, electrode manufacturing, electrolyte battery manufacturing, etc., can solve problems such as hindering lithium ion intercalation and extraction, reducing material specific capacity, increasing mass transfer resistance, etc., to facilitate industrial scale-up production, Broad application prospects and the effect of reducing interface resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

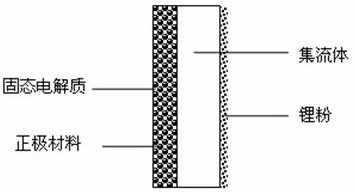

[0040] The present invention provides a method of integrating high-performance electrodes comprising the step of: first dispersion of a positive electrode material, a binder in a solid electrolyte solution, and then spray mixed positive electrode suspension into a set The positive electrode composite electrode is formed on the fluid. After the solvent is completely volatilized, the lithium powder is directly sprayed directly on the opposite side of the collector, i.e., the integrated high-performance electrode for solid state cells.

[0041] Preferably, the method of preparing the integrated high performance electrode is as follows:

[0042] 1) Complete solid electrolyte is completely dissolved in solvent to form a solid electrolyte solution;

[0043] 2) In the solid electrolyte solution, the ultrasonic dispersion is uniform, and the mixed positive electrode suspension is generated.

[0044] 3) Add the mixed positive electrode suspension to the spray gun, using nitrogen as carrier g...

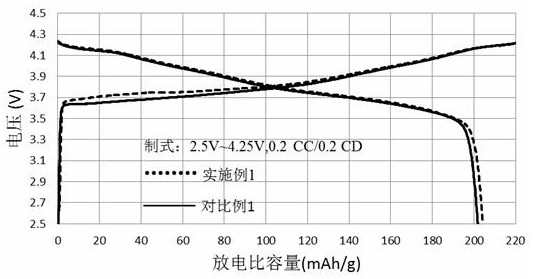

Embodiment 1

[0059] A method for the preparation of high performance electrodes, the specific steps are as follows:

[0060] 1) 100 g of PEO is completely dissolved in 50 ml of ethanol solution to form a solid electrolyte solution;

[0061] 2) 10 g of NCM811 material, 20 ml 5 wt.% Nafion solution, the ultrasonic dispersion is uniform, and the ultrasonic dispersion is uniform, forming a mixed positive suspension;

[0062] 3) Add the mixed positive electrode suspension into the spray gun, using nitrogen as the carrier gas, slowly spray it to the surface of the copper foil, sprayed the layer, to evaporate, repeatedly sprayed it, repeatedly sprayed all of them. After obtaining the positive electrode composite electrode;

[0063] 4) A 10 g of lithium powder is placed in an injector of the electrostatic spraying apparatus, and the lithium powder is sprayed on the opposite side of the positive electrode composite electrode aggregate fluid, i.e., the integrated high-performance electrode.

[0064] The...

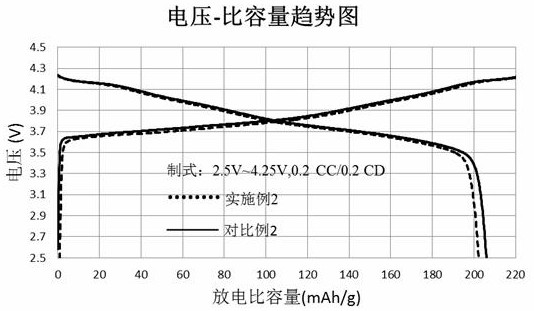

Embodiment 2

[0068] A method for the preparation of high performance electrodes, the specific steps are as follows:

[0069] 1) 100 g of PEO is completely dissolved in 50 ml of ethanol solution to form a solid electrolyte solution;

[0070] 2) In the solid-state electrolyte solution prepared by 20 g of NCM811 material, 10 ml 5 wt.% Nafion solution, ultrasonic dispersion is uniform, and the hypervisor is formed, and the mixed positive electrode suspension is formed;

[0071] 3) Add the mixed positive electrode suspension into the spray gun, using nitrogen as the carrier gas, slowly spray it to the surface of the copper foil, sprayed the layer, to evaporate, repeatedly sprayed it, repeatedly sprayed all of them. After obtaining the positive electrode composite electrode;

[0072] 4) A 15 g of lithium powder is placed in an injector of the electrostatic spraying apparatus, and the lithium powder is sprayed on the opposite side of the positive electrode composite electrode aggregate fluid, i.e., t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com