Grouting material for grouting type composite asphalt pavement

A technology of composite asphalt and grouting material, applied in the field of cement grouting material, can solve the problems of poor grouting joints, settlement of grouting structure, cracks and other problems, and achieve the effects of improving comprehensive performance, promoting uniform dispersion and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

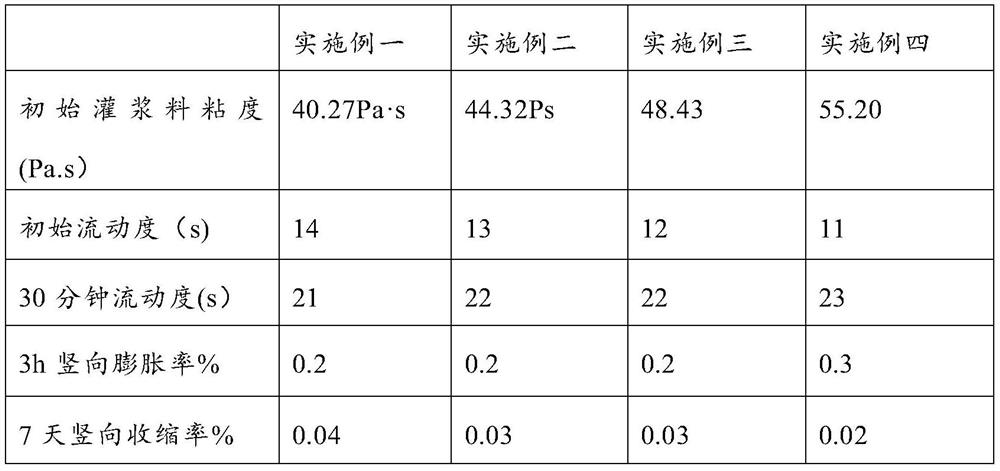

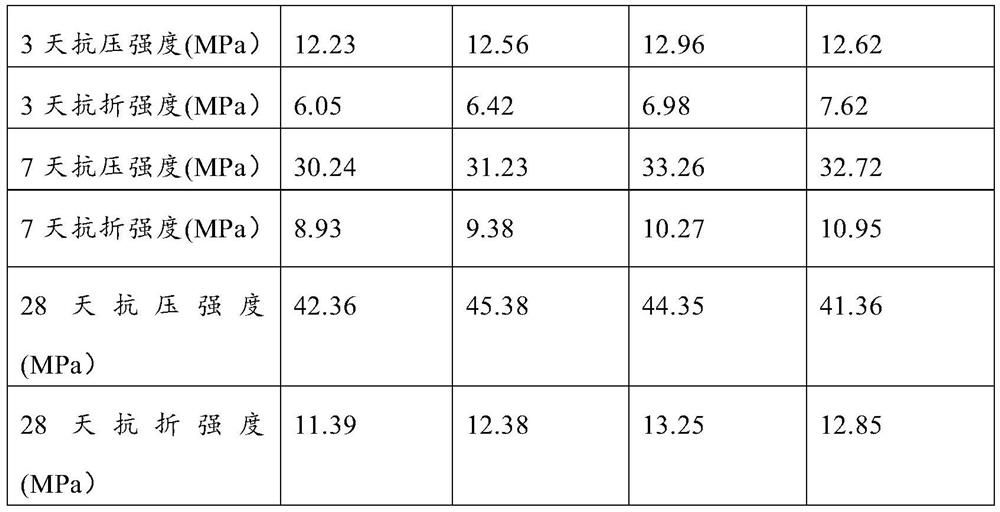

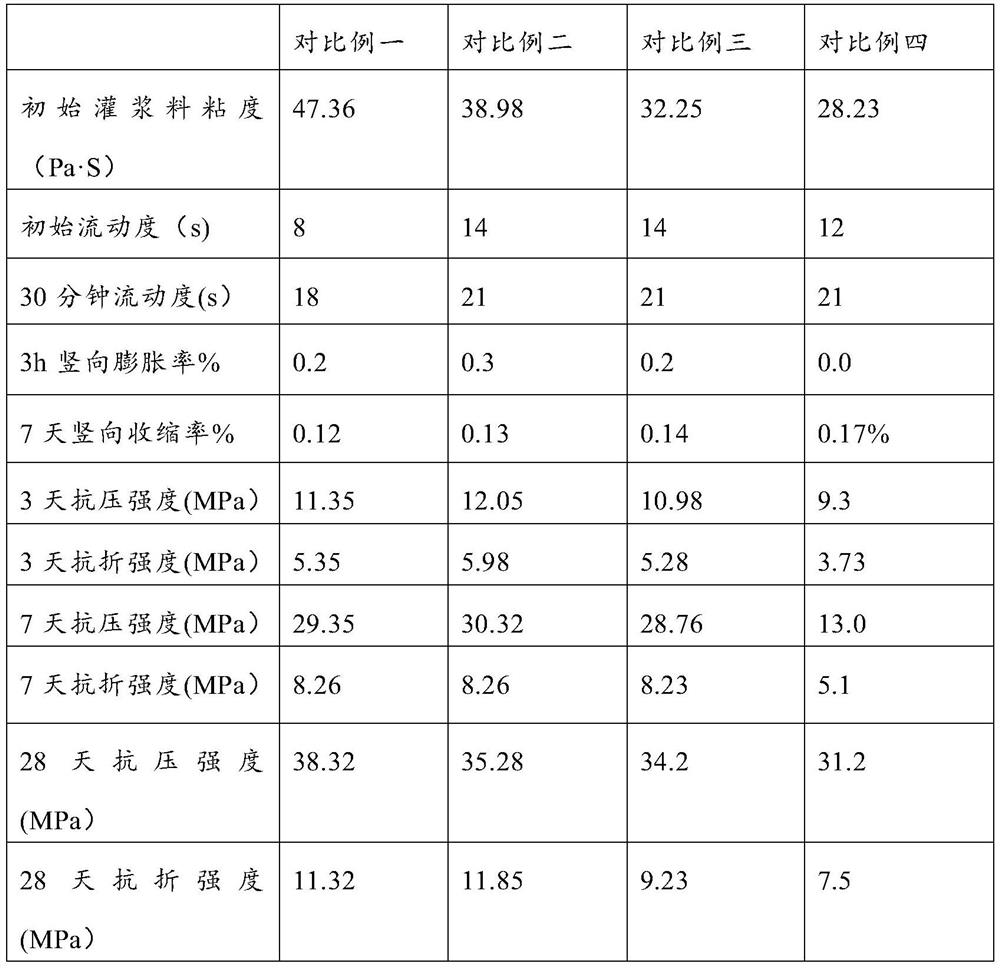

Embodiment 1

[0022] The pour-in composite asphalt pavement grouting material described in this embodiment is prepared by weight ratio from the following raw materials:

[0023] 80 parts of cement (P.O42.5); 5 parts of silicon powder; 15 parts of aeolian sand; 6 parts of mineral powder; 0.05 parts of water reducing agent; 3 parts; 0.3 parts of lithium carbonate; 0.1 parts of expansion agent; 10 parts of polydimethylsiloxane; 2 parts of methyl vinyl bis (N-methylacetamido) silane; share;

[0024] Specifically, when preparing the grouting material at the construction site, add water accounting for 18% of the total mass of raw materials to mix the above raw materials.

Embodiment 2

[0026] The pour-in composite asphalt pavement grouting material described in this embodiment is prepared by weight ratio from the following raw materials:

[0027] 65 parts of cement (P.O42.5); 8 parts of silicon powder; 20 parts of aeolian sand; 10 parts of mineral powder; 0.5 parts of water reducing agent; 0.4 parts of lithium carbonate; 0.1 parts of expansion agent; 15 parts of polydimethylsiloxane; 5 parts of methylvinylbis(N-methylacetamido)silane; 5 parts of N,N-dimethylformamide ;

[0028] Specifically, when preparing the grouting material at the construction site, add water accounting for 16% of the total mass of raw materials to mix the above raw materials.

Embodiment 3

[0030] 50 parts of cement (P.O42.5); 12 parts of silicon powder; 26 parts of aeolian sand; 15 parts of mineral powder; 1.5 parts of water reducing agent; 0.3 parts of bentonite; 5 parts; 0.5 parts of lithium carbonate; 0.15 parts of expansion agent; 20 parts of polydimethylsiloxane; 8 parts of methylvinylbis(N-methylacetamido) silane; share;

[0031] Specifically, when preparing the grouting material at the construction site, add water accounting for 14% of the total mass of raw materials to mix the above raw materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com