Method for removing zearalenone from natural vitamin E and product obtained by method

A technology of zearalenone and natural vitamins, applied in the direction of organic chemistry, which can solve the problems of low adsorption efficiency, high operation cost, and destruction of nutrients, and achieve the effects of small material loss, simple process and high adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0109] Embodiment 1: remove zearalenone from natural vitamin E

[0110] The implementation steps of this embodiment are as follows:

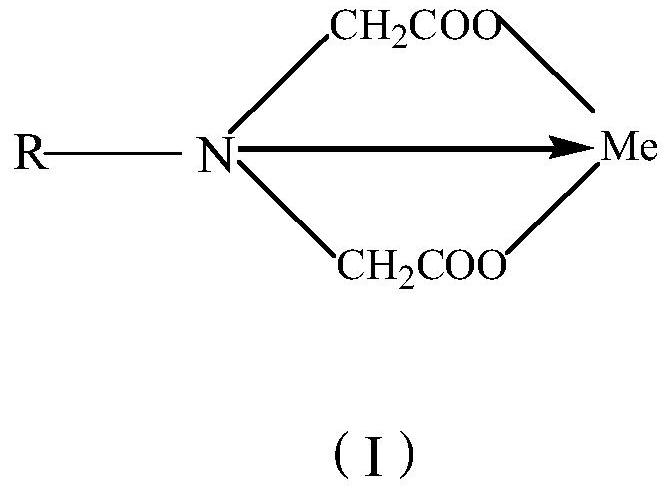

[0111] A. Iminodiacetic acid type chelating resin pretreatment

[0112] Under the room temperature of temperature 26 ℃, according to the ratio of the imine diacetic acid type chelating resin in grams and the deionized water in milliliters is 1:8, let the imine diacetic acid type chelating resin sold by Mitsubishi Chemical Corporation under the trade name DIAION CR-11 be 1:8. Amine diacetic acid type chelating resin soaks 3.6 hours in pH 8 deionized waters, makes this chelating resin fully swell, then is 3.0 according to the ratio of iminodiacetic acid type chelating resin in grams and milliliter saturated sulfate solution , allowing the fully swollen chelating resin to be soaked in saturated sodium sulfate solution for 0.8 hours, followed by washing with deionized water according to the ratio of soaking chelating resin in grams to deionized wat...

Embodiment 2

[0121] Embodiment 2: remove zearalenone from natural vitamin E

[0122] The implementation steps of this embodiment are as follows:

[0123] A. Iminodiacetic acid type chelating resin pretreatment

[0124] Under the room temperature of temperature 20 ℃, according to the ratio of imine diacetic acid type chelating resin in grams and the deionized water in milliliters is 1:10, let the diacetate sold under trade name DIAION CR-11 by Mitsubishi Chemical Co., Ltd. Aminodiacetic acid type chelating resin soaked 4.4 hours in pH 6 deionized water, made this chelating resin fully swell, then according to the ratio of iminodiacetic acid type chelating resin in grams and in milliliters saturated sulfate solution is 1.0 , allowing the fully swollen chelating resin to be soaked in saturated potassium sulfate solution for 1.0 hour, followed by washing with deionized water in the same way as the ratio of soaking the chelating resin in grams to deionized water in milliliters is 2 Washing 3 ...

Embodiment 3

[0133] Embodiment 3: remove zearalenone from natural vitamin E

[0134] The implementation steps of this embodiment are as follows:

[0135] A. Iminodiacetic acid type chelating resin pretreatment

[0136] At room temperature at a temperature of 24° C., the ratio of imine diacetic acid type chelating resin in grams to deionized water in milliliters is 1:5. Amine diacetic acid type chelating resin soaks 3.0 hours in pH 10 deionized water, makes this chelating resin fully swell, then according to the ratio of iminodiacetic acid type chelating resin in gram and in milliliter saturated sulfate solution is 1.6 , allowing the fully swollen chelating resin to be soaked in saturated ammonium sulfate solution for 1.2 hours, followed by soaking the chelating resin in grams and deionized water in milliliters in a ratio of 4 and washing with deionized water in the same manner Washing 3 times, drying at a temperature of 42°C to obtain a modified chelating resin;

[0137] B. Column packi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com