Flame-retardant antibacterial PVC material and preparation method thereof

A PVC material and PVC resin technology, applied in the field of plastics, can solve the problems of poor antibacterial specificity, high flammability, and weak binding force, etc., to reduce the amount of combustibles produced, good flame retardancy, and reduce the speed of mass loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0034] The preparation method of antibacterial flame retardant is as follows:

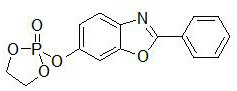

[0035] S1. Mix and dissolve 1mol ethylene glycol and 1.2mol phosphorus oxychloride in 200mL dichloromethane, add 0.2mol aluminum trichloride, reflux at 45°C for 3h, add 200mL saturated sodium carbonate solution, filter, and dichloromethane for solids Washing and drying at 90°C for 2 hours gave Intermediate A, the structure of which was shown in Formula II;

[0036]

[0037] Formula II;

[0038] synthetic route:

[0039]

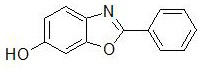

[0040] S2. Dissolve 1 mol of 4-aminobenzene-1,3-diol in 200 mL of dichloromethane, add 1.02 mol of benzoic acid and 0.5 mol of polyphosphoric acid, react at reflux at 45°C for 5 hours, add 200 mL of saturated sodium carbonate solution, and filter , the solid was washed with dichloromethane and dried to obtain intermediate B, the structure of which is shown in formula III;

[0041]

[0042] Formula III;

[0043] synthetic route:

[0044]

[0045] S3. Dissolve 1.01 ...

preparation example 2

[0049] The preparation method of antibacterial flame retardant is as follows:

[0050] S1. Mix and dissolve 1mol ethylene glycol and 1.5mol phosphorus oxychloride in 200mL dichloromethane, add 0.3mol aluminum trichloride, reflux at 45°C for 6h, add 200mL saturated sodium carbonate solution, filter, and dichloromethane for solids Washing, drying at 90°C for 2 hours to obtain Intermediate A;

[0051] S2. Dissolve 1mol of 4-aminobenzene-1,3-diol in 200mL of dichloromethane, add 1.1mol of benzoic acid and 1mol of polyphosphoric acid, react for 5-10h under reflux at 45°C, add 200mL of saturated sodium carbonate solution, Filtration, the solid was washed with dichloromethane, and dried to obtain intermediate B;

[0052] S3. Dissolve 1.05 mol of intermediate B in 200 mL of dichloromethane, under nitrogen protection, add 1 mol of intermediate A and 3 mol of triethylamine, react at 0°C for 2 hours, add 200 mL of saturated sodium carbonate solution, filter, and wash the solid with dich...

preparation example 3

[0054] The preparation method of antibacterial flame retardant is as follows:

[0055] S1. Mix and dissolve 1mol ethylene glycol and 1.35mol phosphorus oxychloride in 200mL dichloromethane, add 0.25mol aluminum trichloride, reflux at 45°C for 4 hours, add 200mL saturated sodium carbonate solution, filter, and dichloromethane Washing, drying at 90°C for 2 hours to obtain Intermediate A;

[0056] S2. Dissolve 1 mol of 4-aminobenzene-1,3-diol in 200 mL of dichloromethane, add 1.06 mol of benzoic acid and 0.7 mol of polyphosphoric acid, react at 45°C for 7 hours, add 200 mL of saturated sodium carbonate solution, and filter , the solid was washed with dichloromethane and dried to obtain Intermediate B;

[0057] S3. Dissolve 1.03 mol of intermediate B in 200 mL of dichloromethane, under nitrogen protection, add 1 mol of intermediate A and 3 mol of triethylamine, react at 0°C for 1.5 h, add 200 mL of saturated sodium carbonate solution, filter, and distill the solid with di Wash w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com