Water-based hydrophobic slurry as well as preparation method and application thereof

A hydrophobic and water-based technology, applied in the field of water-based hydrophobic slurry and its preparation, can solve problems such as use, and achieve the effects of solving environmental pollution, simple and environmentally friendly preparation, high separation efficiency and flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] The water-based hydrophobic slurry is prepared by the following steps:

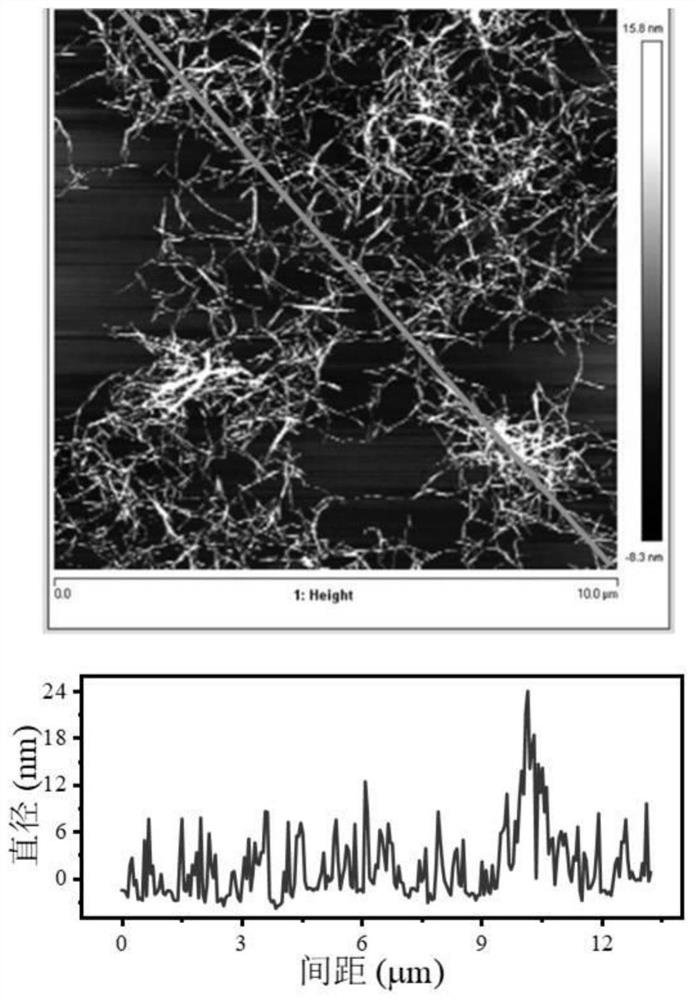

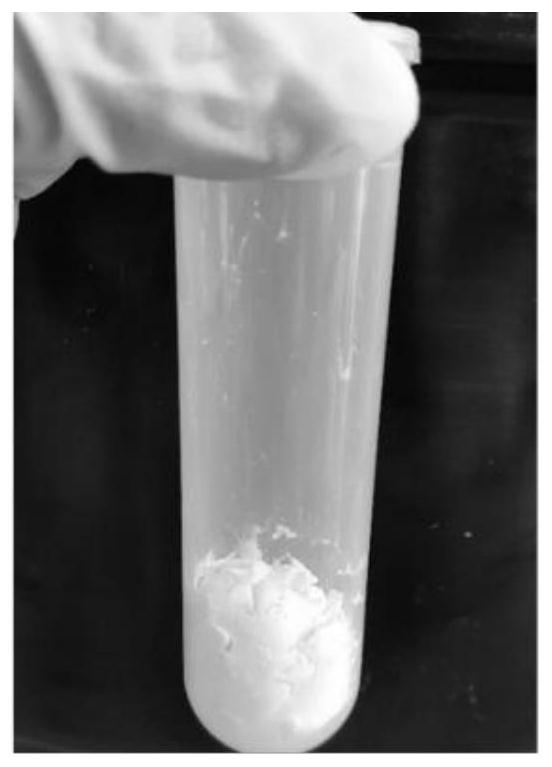

[0064] (1) Preparation of silica premix: 100g of nanocellulose liquid prepared from pulp raw materials (2g of cellulose dry weight, the rest is water. The morphology and size of cellulose are as follows: figure 1 As shown, its diameter is 2-24nm, length is 1-15μm) with 10g hexamethyldisilazane modified nano-silica (diameter is 10nm), 4g sodium stearate, monoglyceride and stearin The acid mixture (the mass ratio of sodium stearate, monoglyceride and stearic acid is 1:0.2:1) was mixed in a high-speed shear mode for 12 minutes at a shear rate of 30000 rpm to obtain a silica premix. The prepared silica premix is a paste, and the photo of the silica premix is shown in figure 2 ;

[0065] (2) Preparation of water-based hydrophobic slurry: 100g of nanocellulose liquid (dry weight 2g, the rest is water) and 100g of water are stirred and mixed to obtain a nanocellulose dispersion;

[0066] (3) Mix 1...

Embodiment 2

[0071] The water-based hydrophobic slurry is prepared by the following steps:

[0072] (1) Preparation of silica premix: 100g of nanocellulose liquid prepared from pulp raw materials (2g of cellulose dry weight, the rest is water. The morphology and size of cellulose are as follows: figure 1 As shown, its diameter is 2-24nm, length is 1-15μm) with 10g hexamethyldisilazane modified nano-silica (diameter is 10nm), 4g sodium stearate, monoglyceride and stearin The acid mixture (the mass ratio of sodium stearate, monoglyceride and stearic acid is 1:0.2:1) was mixed in a high-speed shear mode for 12 minutes at a shear rate of 30000 rpm to obtain a silica premix. The prepared silicon dioxide premix is paste;

[0073] (2) Preparation of water-based hydrophobic slurry: 100g of nanocellulose liquid (dry weight 2g, the rest is water) and 100g of water are stirred and mixed to obtain a nanocellulose dispersion;

[0074] (3) 13.25 g (dry weight 1.86 g) of the silica premix prepared in...

Embodiment 3

[0077] The water-based hydrophobic slurry is prepared by the following steps:

[0078](1) Preparation of silica premix: 100g of nanocellulose liquid prepared from pulp raw materials (2g of cellulose dry weight, the rest is water. The morphology and size of cellulose are as follows: figure 1 As shown, its diameter is 2-24nm, length is 1-15μm) with 5g hexamethyldisilazane modified nano silicon dioxide (diameter is 10nm), 2g sodium stearate, monoglyceride and stearin The acid mixture (the mass ratio of sodium stearate, monoglyceride and stearic acid is 1:0.2:1) was mixed in a high-speed shear mode for 12 minutes at a shear rate of 30000 rpm to obtain a silica premix. The prepared silicon dioxide premix is paste;

[0079] (2) Preparation of water-based hydrophobic slurry: 100g of nanocellulose liquid (dry weight 2g, the rest is water) and 100g of water are stirred and mixed to obtain a nanocellulose dispersion;

[0080] (3) 11.41g (dry weight 0.96g) of the silica premix prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com