Electrolyte plasma polishing method for titanium alloy femoral stem prosthesis

A plasma and titanium alloy technology, applied in the field of plasma polishing, can solve the problems of high dependence on the surface quality of workers, large noise pollution in the working environment, endangering the health of operators, etc. Hazards to worker health, no effect of noise pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

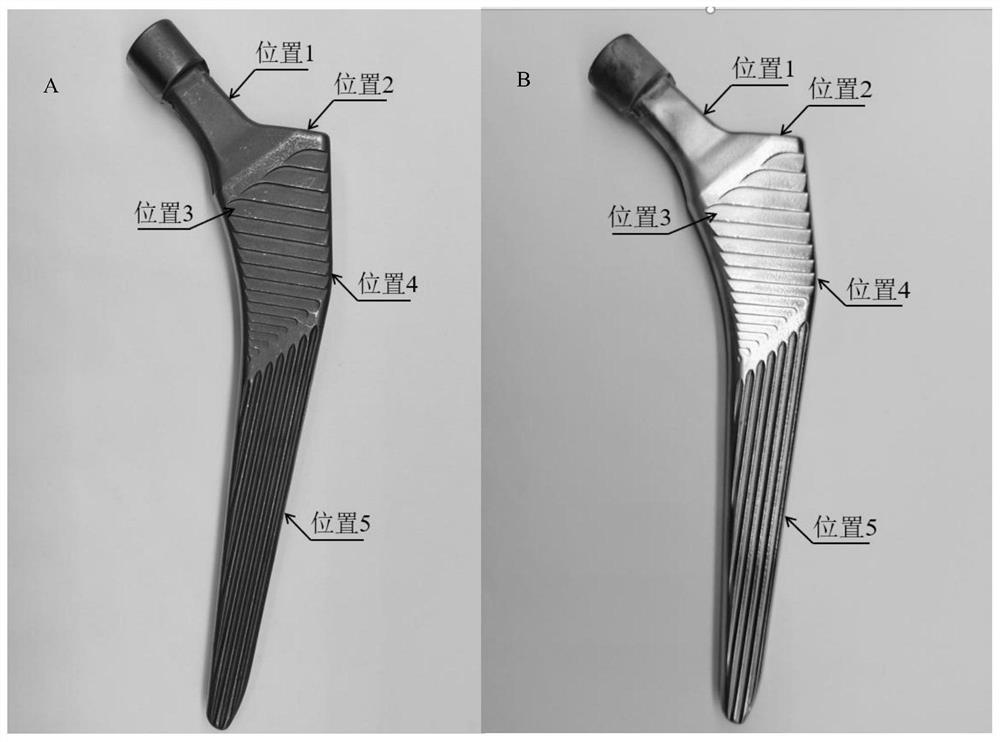

Image

Examples

Embodiment 1

[0033] A kind of electrolyte plasma polishing method of titanium alloy femoral stem prosthesis, comprises the following steps:

[0034] Step 1, preparation of polishing liquid:

[0035] Step 1.1, calculate the amount of each solute according to the total volume of the polishing solution to be configured. The solute includes ammonium fluoride and potassium fluoride. The total volume of the prepared polishing solution is 1L. The amount of each solute is: ammonium fluoride: 5g, fluoride Potassium: 30g;

[0036] Step 1.2, according to the calculation results, weigh ammonium fluoride and potassium fluoride into the container, add deionized water to reach the total volume, stir and dissolve to obtain the polishing solution, and set aside;

[0037] Step 2, electrolyte plasma polishing treatment:

[0038] Step 2.1, put the polishing solution prepared in step 1 in the polishing pool, and heat it in a constant temperature water bath and keep the temperature at 75°C;

[0039] Step 2.2...

Embodiment 2

[0050] A kind of electrolyte plasma polishing method of titanium alloy femoral stem prosthesis, comprises the following steps:

[0051] Step 1, preparation of polishing liquid:

[0052] Step 1.1, calculate the amount of each solute according to the total volume of the polishing solution to be configured. The solute includes ammonium fluoride and potassium fluoride. The total volume of the prepared polishing solution is 1L. The amount of each solute is: ammonium fluoride: 3g, fluoride Potassium: 10g;

[0053] Step 1.2, according to the calculation results, weigh ammonium fluoride and potassium fluoride into the container, add deionized water to reach the total volume, stir and dissolve to obtain the polishing solution, and set aside;

[0054] Step 2, electrolyte plasma polishing treatment:

[0055] Step 2.1, put the polishing solution prepared in step 1 in the polishing pool, and heat it in a constant temperature water bath and keep the temperature at 70°C;

[0056] Step 2.2...

Embodiment 3

[0063] A kind of electrolyte plasma polishing method of titanium alloy femoral stem prosthesis, comprises the following steps:

[0064] Step 1, preparation of polishing liquid:

[0065] Step 1.1, calculate the amount of each solute according to the total volume of the polishing solution to be configured. The solute includes ammonium fluoride and potassium fluoride. The total volume of each preparation is 1L of polishing solution. The amount of each solute is: ammonium fluoride: 25g, fluoride Potassium chloride: 60g;

[0066] Step 1.2, according to the calculation results, weigh ammonium fluoride and potassium fluoride into the container, add deionized water to reach the total volume, stir and dissolve to obtain the polishing solution, and set aside;

[0067] Step 2, electrolyte plasma polishing treatment:

[0068] Step 2.1, put the polishing solution prepared in step 1 in the polishing pool, and heat it in a constant temperature water bath and keep the temperature at 90°C; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com