Biomass carbon material derived transition metal-based catalyst, preparation method and application thereof, and solid-state zinc-air battery

A technology of transition metals and biomass carbon, applied in fuel cell half-cells and primary battery half-cells, battery electrodes, circuits, etc., can solve problems that limit the popularization and application of zinc-air batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

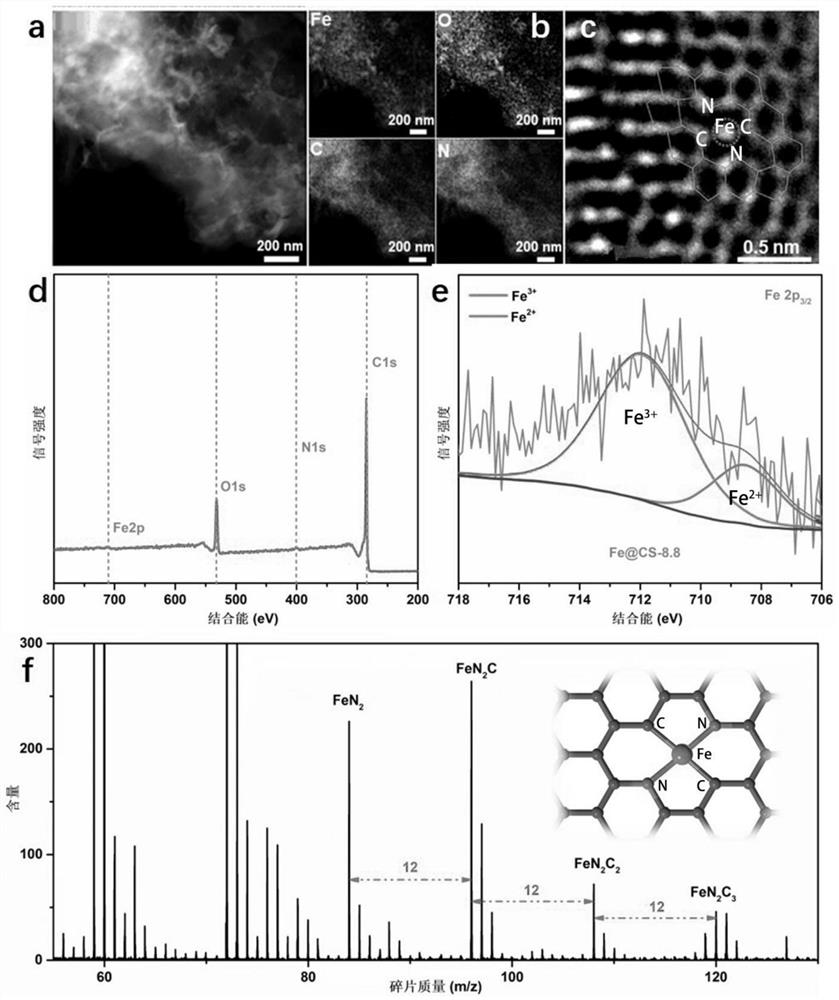

[0031] The invention provides a method for preparing a transition metal-based catalyst derived from a biomass carbon material, comprising the following steps:

[0032] The mushroom spores are pre-carbonized and carbonized in sequence to obtain carbonized products;

[0033] mixing the carbonized product with an activator for activation to obtain a catalyst carrier;

[0034] Mixing the catalyst carrier, transition metal precursor and organic solvent, and calcining to obtain a transition metal-based catalyst derived from a biomass carbon material;

[0035] The transition metal precursor includes m-tetraphenylporphyrin ferric chloride, 5,10,15,20-tetrakis(4-methoxyphenyl)-21H,23H-porphine cobalt or nickel salt.

[0036] In the present invention, unless otherwise specified, the required preparation materials are commercially available products well known to those skilled in the art.

[0037] In the invention, the mushroom spores are pre-carbonized and carbonized in sequence to ob...

Embodiment 1

[0060] Place the mushroom spores in a tube furnace for pre-carbonization at 300°C for 120 min with a heating rate of 1°C / min, and continue to carbonize the resulting product in a tube furnace at 800°C for 2 h in a nitrogen atmosphere at a heating rate of 5°C / min. min, get the carbonized product;

[0061] 90 mg of the carbonized product and 180 mg of potassium hydroxide were mixed and ground with a mortar until the mixture was powdery, and the ground mixture was activated in a tube furnace at 800 ° C for 2 h under a nitrogen atmosphere at a heating rate of 5 ° C / min, the resulting product was centrifuged with ethanol and ultrapure water until the solution was neutral, and then dried in an oven at 60°C to obtain a catalyst carrier;

[0062] Dissolve 10mg m-tetraphenylporphyrin iron (III) chloride in 20mL tetrahydrofuran, place in a fume hood and stir at room temperature for 30min, take 80mg of the above catalyst carrier and disperse it in 40mL tetrahydrofuran, place in a fume ...

Embodiment 2

[0064] The only difference between this example and Example 1 is that the transition metal precursor is replaced with 6.65 mg of 5,10,15,20-tetrakis(4-methoxyphenyl)-21H,23H-porphine cobalt(II), and Tetrahydrofuran was replaced by ethanol, and the mass of the catalyst carrier was replaced by 50 mg. Others were the same as in Example 1. The loading amount of Co atoms on the catalyst carrier was 0.98 wt%, and the obtained catalyst was recorded as Co@CS-8.8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Maximum power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com