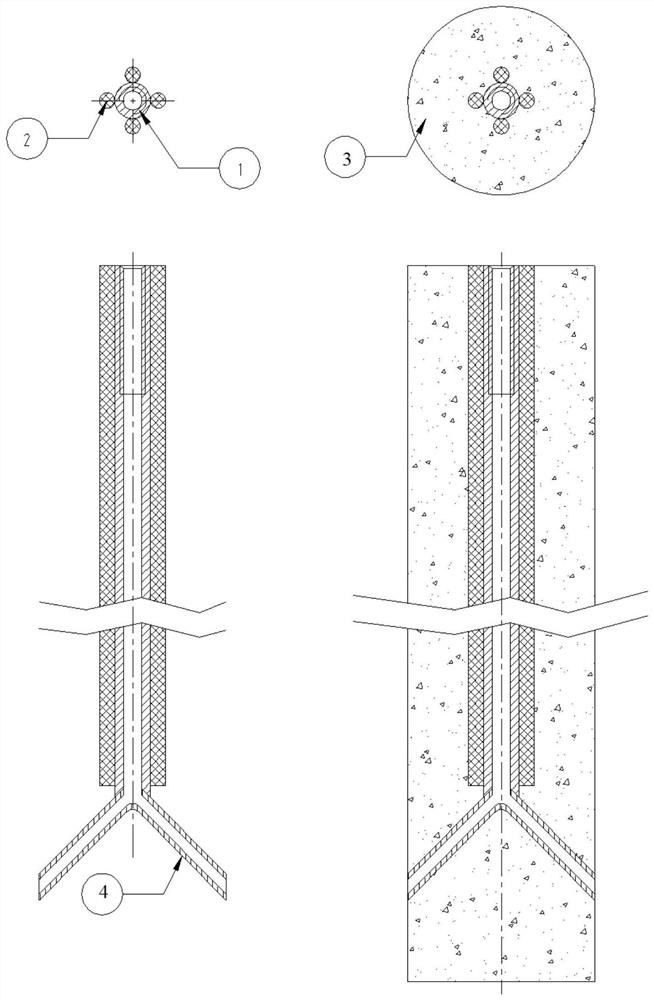

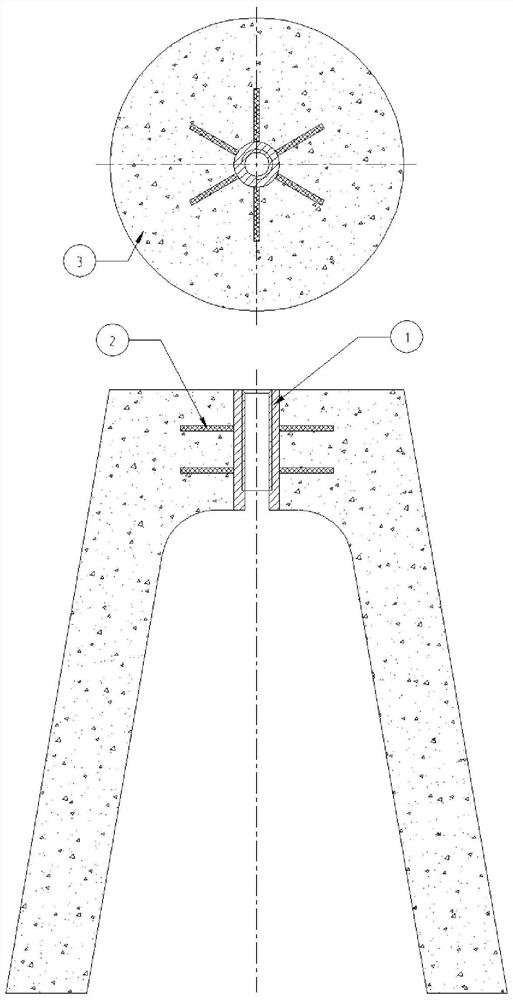

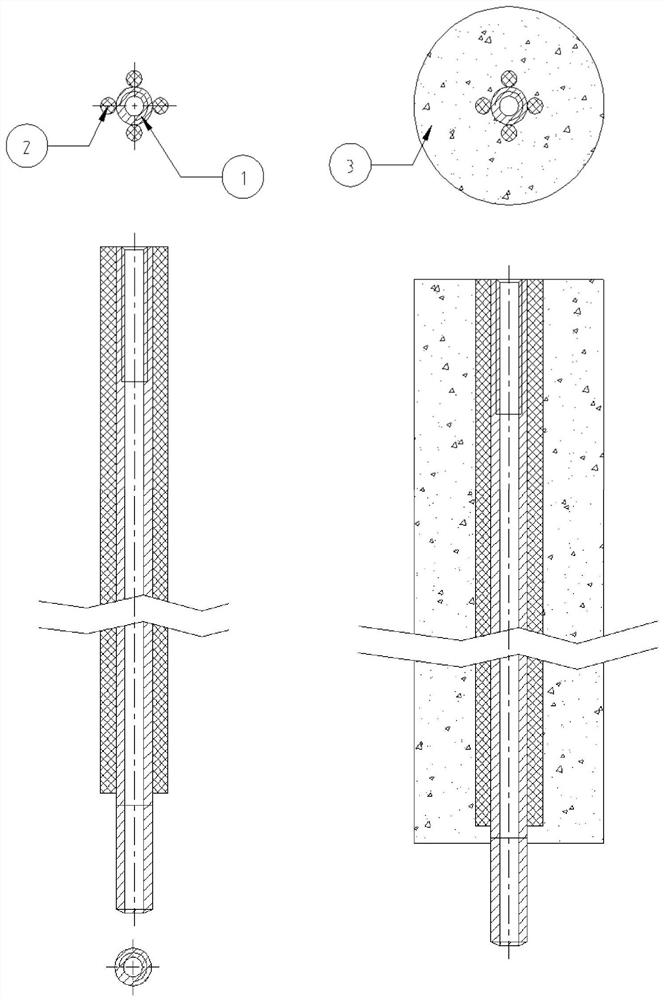

Long-life desulfurization spray gun refractory piece and preparation process thereof

A desulfurization spray gun and refractory technology, applied in the field of refractory materials, can solve the problems of cracks, falling off steel pipes, and fractures of the spray gun refractory materials, and achieve the effects of reducing the generation of cracks, increasing thermal conductivity, and reducing expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A long-lived desulfurization spray gun refractory provided in this embodiment is a carbon-bonded metal plastic refractory material. The particle size composition and addition ratio of each raw material are: 30% of 85 alumina particles with a particle size of 3-1mm, and brown corundum particles with a particle size of 3-1mm 10%, 20% of brown corundum particles with a particle size of 1-0mm, 8% of white corundum fine powder with a particle size of ≤0.088mm, 12% of 95 silicon carbide fine powder with a particle size of ≤0.074mm, 4% of 95 flake graphite with a particle size of ≤0.013mm, 1% of metal aluminum powder with particle size ≤0.088mm, 2% of metal silicon powder with particle size ≤0.088mm, 4% of 75 ferrosilicon alloy powder with particle size ≤0.088mm, 2% of high-temperature asphalt powder with particle size ≤0.10mm, 2% of particle size ≤0.045mm 0.5% boron carbide, 1.5% boron glass with a particle size ≤ 0.10mm, 5% liquid thermosetting phenolic resin with a viscosity...

Embodiment 2

[0030] A long-lived desulfurization spray gun refractory provided in this embodiment is a carbon-bonded metal plastic refractory material. The particle size composition and addition ratio of each raw material are: 35% of brown corundum particles with a particle size of 3-1mm, and 20% of brown corundum particles with a particle size of 1-0mm. %, 8% white corundum fine powder with particle size ≤0.088mm, 15% 97 silicon carbide fine powder with particle size ≤0.074mm, 5% 95 flake graphite with particle size ≤0.013mm, 2% metal aluminum powder with particle size ≤0.088mm, particle size 4% metal silicon powder ≤0.088mm, 2% 75 ferrosilicon alloy powder with particle size ≤0.088mm, 3% high-temperature asphalt powder with particle size ≤0.10mm, 1% boron carbide with particle size ≤0.045mm, liquid thermosetting phenolic resin with viscosity 6200cp 5%.

Embodiment 3

[0032] A long-lived desulfurization spray gun refractory provided in this embodiment is a carbon-bonded metal plastic refractory material. The particle size composition and addition ratio of each raw material are: 5% of burnt gemstone particles with a particle size of 5-3mm, and 10% of burnt gemstone particles with a particle size of 3-1mm %, 28% of 85 alumina particles with a particle size of 3-1mm, 20% of brown corundum particles with a particle size of 1-0mm, 10% of brown corundum fine powder with a particle size of ≤0.088mm, 10% of 95 silicon carbide fine powder with a particle size of ≤0.074mm, 5% of 95 flake graphite with a particle size of ≤0.013mm, 1.5% of metal aluminum powder with a particle size of ≤0.088mm, 1% of metal silicon powder with a particle size of ≤0.088mm, 5% of 75 ferrosilicon powder with a particle size of ≤0.088mm, and 5% of a particle size of ≤0.10mm 2.5% of high-temperature asphalt powder, 0.5% of boron carbide with a particle size of ≤0.045mm, 1% of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com