Supercapacitor electrode powder material and preparation method thereof

A supercapacitor and electrode powder technology, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc., can solve the problems of poor fluidity of positive electrode materials, difficult electrolyte penetration and unfavorable electrode coating tap density, etc., to achieve Good porosity, good sphericity, high dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

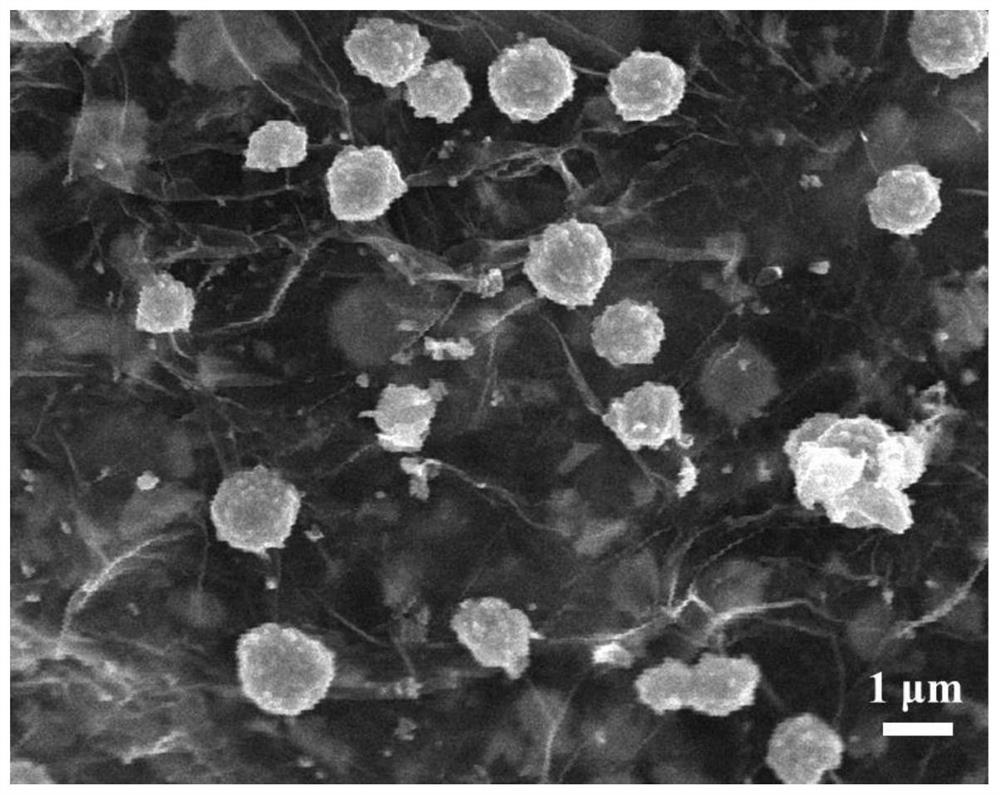

Embodiment 1

[0073] The embodiment of the present invention also provides a method for preparing a supercapacitor electrode powder material, which is specifically implemented according to the following steps:

[0074] Step 1, using Co(NO 3 ) 2 , Fe(NO 3 ) 3 , and Na 2 SeO 4 For cobalt source, iron source and selenium source, respectively weigh Co(NO 3 ) 2 , Fe(NO 3 ) 3 , and Na 2 SeO 4 ;

[0075] Step 2, ethanol and deionized water are configured according to the volume ratio of 2:1;

[0076] Step 3, the Co(NO 3 ) 2 , Fe(NO 3 ) 3 , and Na 2 SeO 4 Dissolve in a mixed solution of 500ml ethanol and deionized water, stir magnetically for 30 minutes to form a red transparent solution;

[0077] Step 4, taking a certain amount of polyethylene glycol as a binder, and the mass ratio of polyethylene glycol and cobalt nitrate is 5:1.

[0078] Step 5, adding polyethylene glycol dropwise to the solution in step 1.3, the dropping rate is 10 drops / min, while maintaining strong magnetic...

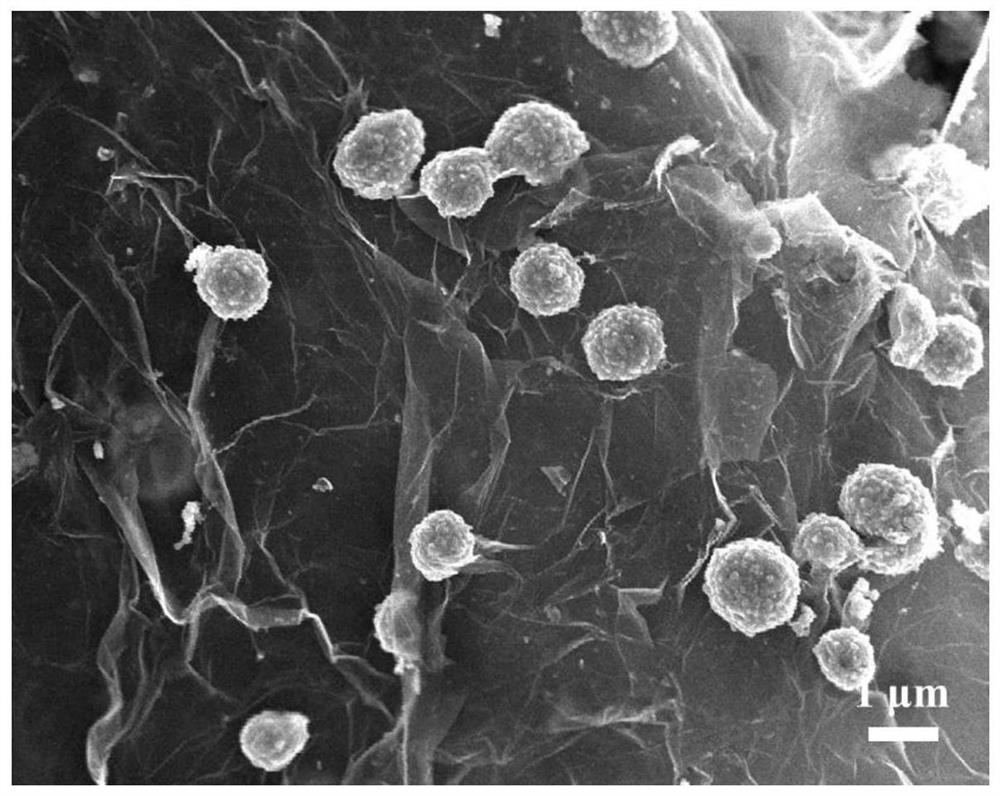

Embodiment 2

[0093] The embodiment of the present invention also provides a supercapacitor electrode powder material Co 0.9 Fe 0.1 The preparation method of Se is specifically implemented according to the following steps:

[0094] Step 1, using Co(NO 3 ) 2 , Fe(NO 3 ) 3 , and Na 2 SeO 4 For cobalt source, iron source and selenium source, respectively weigh Co(NO 3 ) 2 , Fe(NO 3 ) 3 , and Na 2 SeO 4 ;

[0095] Step 2, ethanol and deionized water are configured according to the volume ratio of 2:1;

[0096] Step 3, the Co(NO 3 ) 2 , Fe(NO 3 ) 3 , and Na 2 SeO 4 Dissolve in a mixed solution of 500ml ethanol and deionized water, stir magnetically for 20 minutes to form a red transparent solution;

[0097] Step 4, taking a certain amount of polyethylene glycol as a binder, and the mass ratio of polyethylene glycol and cobalt nitrate is 3:1.

[0098] Step 5, adding polyethylene glycol dropwise to the solution in step 1.3, the dropping rate is 7 drops / min, while maintaining s...

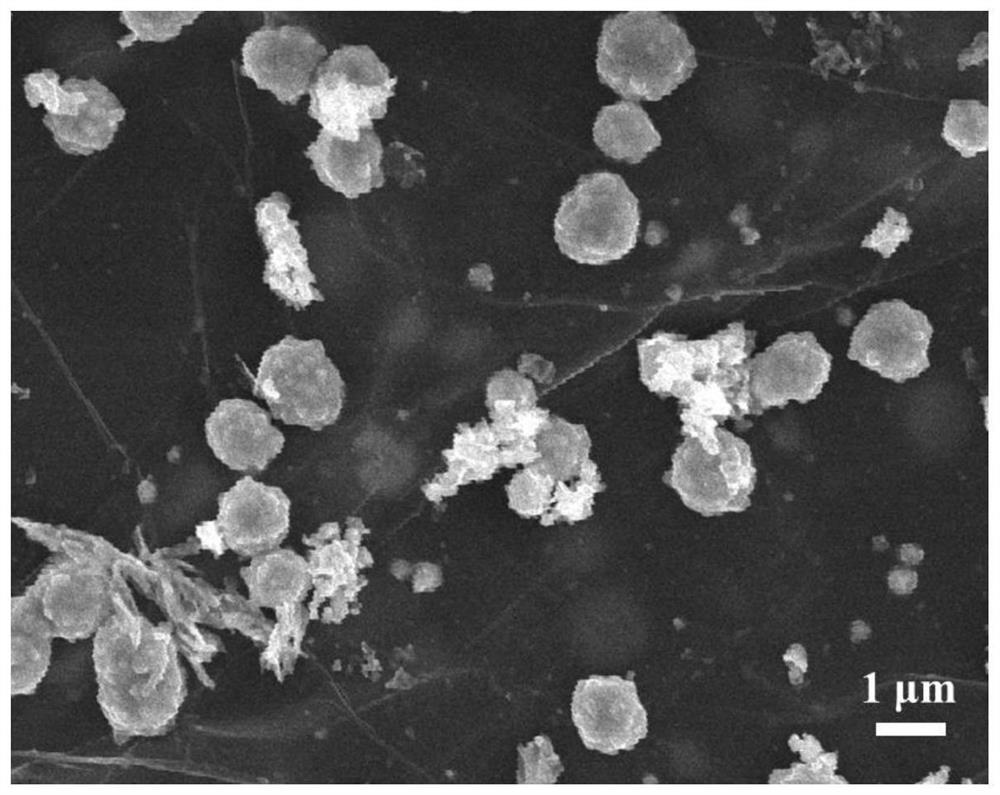

Embodiment 3

[0113] The embodiment of the present invention also provides a supercapacitor electrode powder material Co 0.8 Fe 0.2 The preparation method of Se is specifically implemented according to the following steps:

[0114] Step 1, using Co(NO 3 ) 2 , Fe(NO 3 ) 3 , and Na 2 SeO 4 Cobalt source, iron source and selenium source, according to the molar ratio of 1.15:0.3:1.1 respectively weigh Co(NO 3 ) 2 , Fe(NO 3 ) 3 , and Na 2 SeO 4 ;

[0115] Step 2, ethanol and deionized water are configured according to the volume ratio of 2:1;

[0116] Step 3, the Co(NO 3 ) 2 , Fe(NO 3 ) 3 , and Na 2 SeO 4 Dissolve in a mixed solution of 500ml ethanol and deionized water, stir magnetically for 20 minutes to form a red transparent solution;

[0117] Step 4, taking a certain amount of polyethylene glycol as a binder, and the mass ratio of polyethylene glycol and cobalt nitrate is 6:1.

[0118] Step 5, adding polyethylene glycol dropwise to the solution in step 1.3, the dropping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com