Microporous magnesia-hercynite brick for cement rotary kiln firing zone and preparation method thereof

A magnesium-iron-aluminum spinel and cement rotary kiln technology, which is applied in the field of refractory materials, can solve the problems of high thermal conductivity and large coal consumption, and achieve the effects of reducing thermal conductivity, energy consumption, and heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

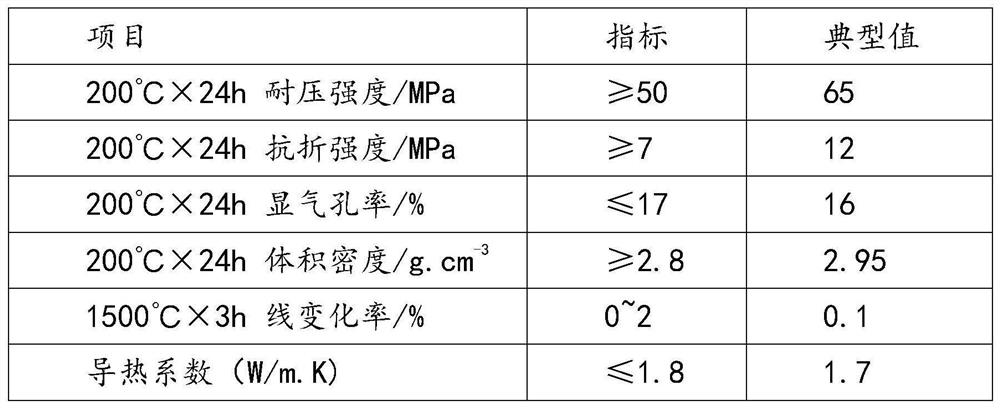

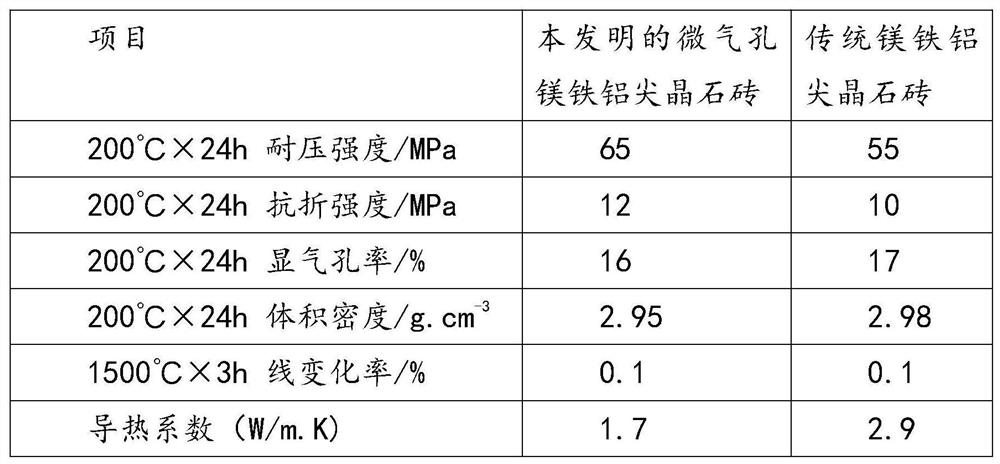

Examples

Embodiment 1

[0027] Embodiment 1: A microporous magnesium-iron-aluminum spinel brick for the firing zone of a cement rotary kiln, including the following raw materials in proportions by weight: 30-40% of microporous high-purity magnesia, and the microporous high-purity magnesia is composed of 5 5-10% of ~3mm microporous high-purity magnesia and 20-30% of 3-1mm microporous high-purity magnesia, 30-40% of fused magnesia, and the fused magnesia consists of 20-30 % and 10-20% of 200 mesh fused magnesia, 5-10% of fused iron-aluminum spinel, 1-2% of poly light balls, the poly light balls are 0.1 to 0.3 poly light particles, the industrial Manganese powder is 200 mesh manganese powder, silica sol 1-5%, the pH value of the silica sol is 9.0 to 10.5, the viscosity of the silica sol is less than or equal to 25mpa.s, and the specific gravity of the silica sol is 1.29 to 1.31, Industrial manganese powder 1-2%.

[0028] A method for preparing a microporous magnesium-iron-aluminum spinel brick for a ce...

Embodiment 2

[0036] Embodiment 2: A microporous magnesium-iron-aluminum spinel brick for the firing zone of a cement rotary kiln, comprising the following raw materials in proportions by weight: 30-40% of microporous high-purity magnesia, and the microporous high-purity magnesia is composed of 5 5-10% of ~3mm microporous high-purity magnesia and 20-30% of 3-1mm microporous high-purity magnesia, 30-40% of fused magnesia, and the fused magnesia consists of 20-30 % and 10-20% of 200-mesh fused magnesia, 5-10% of fused iron-aluminum spinel, the industrial manganese powder is 200-mesh manganese powder, 1-5% of silica sol, and the pH of the silica sol The value is 9.0 to 10.5, the viscosity of the silica sol is less than or equal to 25mpa.s, the specific gravity of the silica sol is 1.29 to 1.31, and the industrial manganese powder is 1-2%.

[0037] A method for preparing a microporous magnesium-iron-aluminum spinel brick for a cement rotary kiln firing zone, comprising the following steps:

[...

Embodiment 3

[0045]Embodiment 3: A microporous magnesia-iron-aluminum spinel brick for the firing zone of a cement rotary kiln, comprising the following raw materials in proportions by weight: 30% to 40% of fused magnesia, the fused magnesia consisting of 1 20-30% of ~0mm fused magnesia and 10-20% of 200-mesh fused magnesia, 5-10% of fused iron-aluminum spinel, 1-2% of polylight ball, the polylight ball is 0.1 To 0.3 poly light particles, the industrial manganese powder is 200 mesh manganese powder, 1-5% silica sol, the pH value of the silica sol is 9.0 to 10.5, the viscosity of the silica sol is less than or equal to 25mpa.s, the The proportion of silica sol is 1.29 to 1.31, and industrial manganese powder is 1 to 2%.

[0046] A method for preparing a microporous magnesium-iron-aluminum spinel brick for a cement rotary kiln firing zone, comprising the following steps:

[0047] 1) Take fused magnesia, fused iron-aluminum spinel, industrial manganese powder, polylight balls, and silica sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com