Biomass synthetic resin filtrate reducer for drilling fluid as well as preparation method and application thereof

A technology of synthetic resin and fluid loss reducer, applied in the field of petroleum industry, can solve the problems of large price fluctuation, poor biodegradability, difficult treatment and disposal, etc. green effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

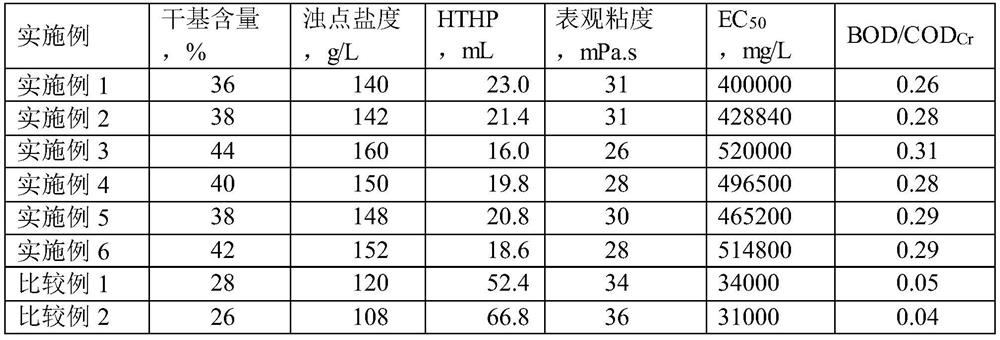

Examples

Embodiment 1

[0044] In parts by weight, extract lignin from 25 parts of corncobs, 50 parts of phenol, 3 parts of hydrochloric acid and 20 parts of 1,3-diisoamylimidazole hexafluorophosphate ([D(i-C 5 )Im][PF 6 ]) The temperature-controlled ionic liquid is added to a three-necked flask with a stirrer, a condensing device and a thermometer in sequence, and the rotation speed is controlled at 180r / min. The oil bath is heated to 105°C for liquefaction for 1 hour. After the reaction is completed, cool to room temperature, and the ionic liquid is solid The ionic liquid after precipitation and separation can be reused, and the liquid phase is liquefied lignin.

[0045] In parts by weight, 100 parts of liquefied lignin obtained, 30 parts of anhydrous sodium sulfite, 35 parts of paraformaldehyde, and 350 parts of water were mixed, reacted at 60°C for 0.5h, continued to heat up to 90°C for 2h, and cooled naturally to room temperature to obtain a biomass synthetic resin fluid loss reducer for drilli...

Embodiment 2

[0048] In parts by weight, 50 parts of enzymatic lignin, 50 parts of phenol, 15 parts of hydrochloric acid and 20 parts of 1,3-bis(2-methylbutyl) imidazole hexafluorophosphate ([D(2 -mb)Im][PF 6 ]) The temperature-controlled ionic liquid is added to a three-necked flask with a stirrer, a condensing device and a thermometer in sequence, and the rotation speed is controlled at 350r / min. The oil bath is heated to 125°C for liquefaction for 3 hours. After the reaction is completed, cool to room temperature, and the ionic liquid is in a solid state. The ionic liquid after precipitation and separation can be reused, and the liquid phase is liquefied lignin.

[0049] In parts by weight, mix 100 parts of the obtained liquefied lignin, 40 parts of sodium metabisulfite, 50 parts of paraformaldehyde, and 600 parts of water, react at 70°C for 1.5h, continue to heat up to 100°C for 4h, and then cool naturally to room temperature , to obtain a biomass synthetic resin fluid loss reducer for...

Embodiment 3

[0052] In parts by weight, 40 parts of lignin derivatives, 50 parts of phenol, 10 parts of hydrochloric acid and 20 parts of 1,3-diisoamylimidazole hexafluorophosphate ([D(i-C 5 )Im][PF 6 ]) The temperature-controlled ionic liquid was added to a three-necked flask with a stirrer, a condensing device and a thermometer in turn, and the rotation speed was controlled at 250r / min. The oil bath was heated to 110°C for liquefaction for 2 hours. After the reaction was completed, it was cooled to room temperature, and the ionic liquid was solid. The ionic liquid after precipitation and separation can be reused, and the liquid phase is liquefied lignin.

[0053] In parts by weight, mix 100 parts of the obtained liquefied lignin, 35 parts of p-aminobenzenesulfonic acid sulfonating agent, 40 parts of paraformaldehyde, and 500 parts of water, react at 65°C for 1h, and continue to heat up to 95°C for 3h. , naturally cooled to room temperature to obtain a biomass synthetic resin fluid loss ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com