Cobalt-molybdenum alloy and cobalt-molybdenum mixed oxide electrocatalyst and preparation method and application thereof

An oxide electrocatalyst technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems that electrocatalysts are rarely reported, and the mechanism of electrocatalyst performance regulation needs to be further studied, so as to enhance the charge transfer efficiency and improve electron transport Efficiency and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

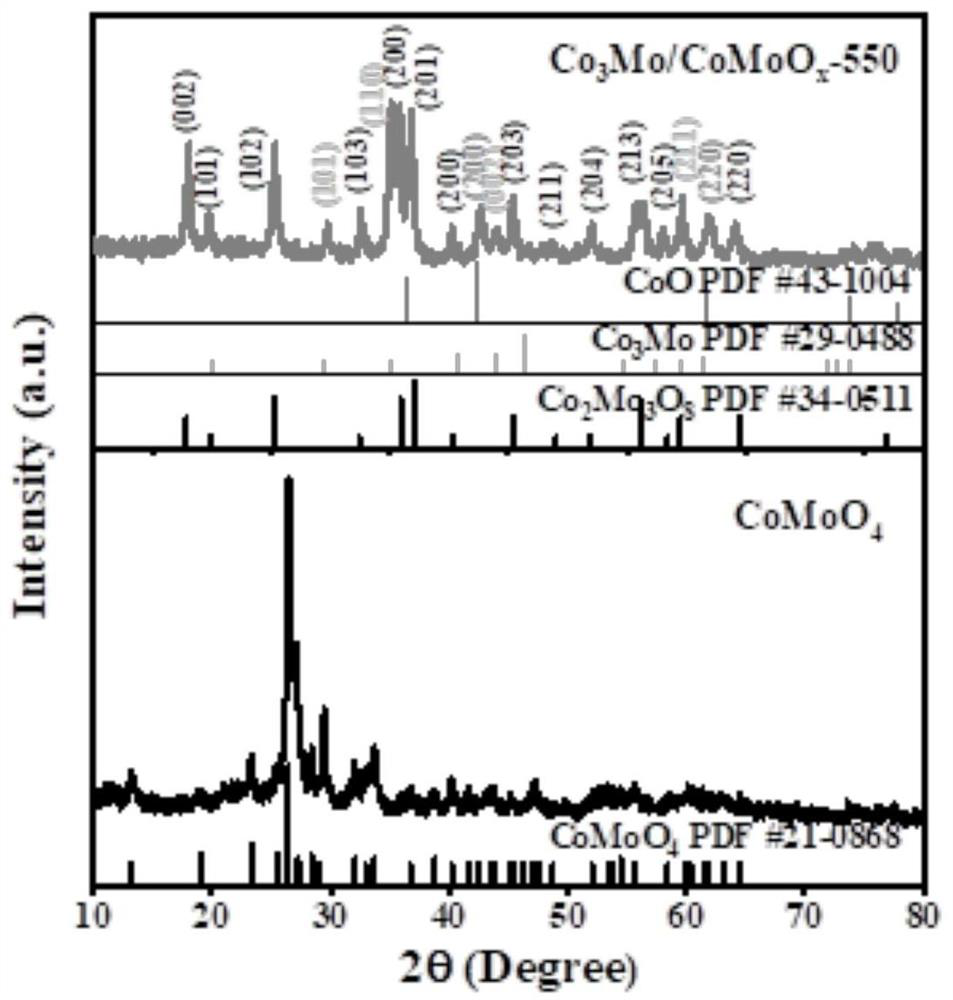

[0032] Cobalt-molybdenum alloy and cobalt-molybdenum mixed oxide electrocatalyst (Co 3 Mo / CoMoO x -550) preparation:

[0033] The nickel foam was ultrasonically cleaned with 3M hydrochloric acid, acetone, absolute ethanol and deionized water in sequence for 30 min, and then dried at 60°C.

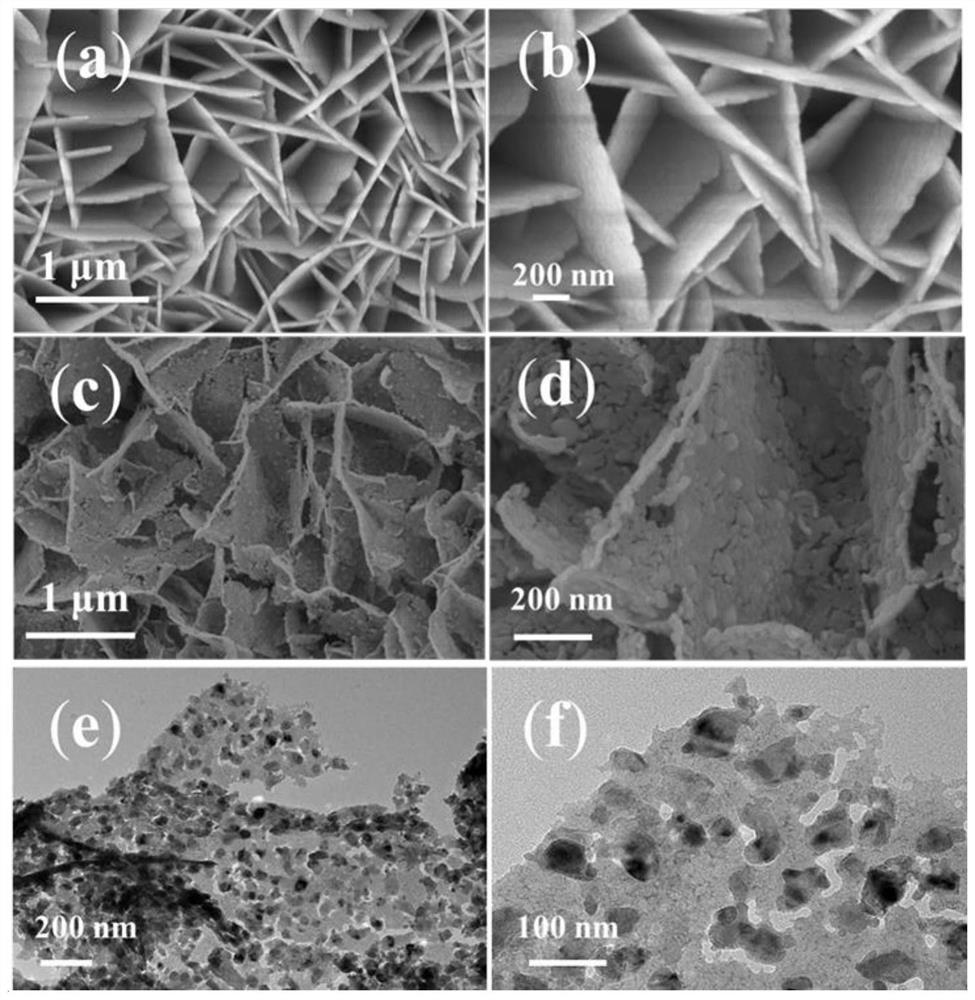

[0034] Weigh 0.291g Co(NO 3 ) 2 ·6H 2 O and 0.241 g Na 2 MoO 4 2H 2 O, add 35mL of deionized water, stir for 30 minutes to obtain a precursor solution, put (2cm×5cm) nickel foam into the precursor solution, transfer it to a 50mL reactor, and heat it at 180°C for 12h until the reaction is complete After that, the color of the foamed nickel turns into lavender, take out the foamed nickel, wash with water and alcohol, dry at 60°C for 12h, and then put it into a tube furnace and anneal at 300°C for 1h under air condition to obtain CoMoO 4 .

[0035] CoMoO prepared above 4 Placed in the crucible, the crucible was transferred to the temperature-raising tube furnace with automatic progra...

Embodiment 2

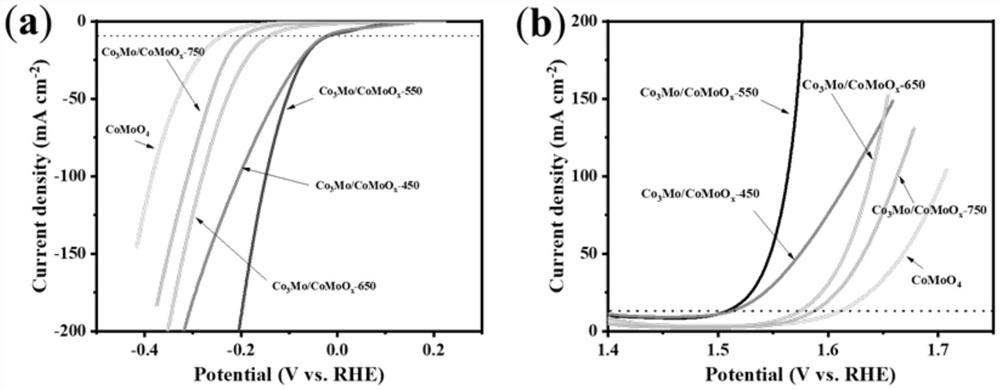

[0037] Cobalt-molybdenum alloy and cobalt-molybdenum mixed oxide electrocatalyst (Co 3 Mo / CoMoO x -450) preparation:

[0038] The preparation method of this electrocatalytic material is basically the same as that of Example 1, the difference is: in H 2 / Ar atmosphere calcination temperature 450 ℃ calcination 2h.

Embodiment 3

[0040] Cobalt-molybdenum alloy and cobalt-molybdenum mixed oxide electrocatalyst (Co 3 Mo / CoMoO x -650) preparation:

[0041] The preparation method of this electrocatalytic material is basically the same as that of Example 1, the difference is: in H 2 / Ar atmosphere calcination temperature 650 ℃ calcination 2h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com