Carbon material containing MN2O2 unit, preparation method and application in NO detection

A technology of MN2O2 and carbon materials, which is applied to the analysis of materials, electrochemical variables of materials, and material analysis through electromagnetic means, etc., which can solve the problems of limited catalytic activity of metal-salen materials, unfavorable nitric oxide sensor material research, difficult sensitive detection, etc. problems, to achieve the best detection results, reduce detection costs, and avoid pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

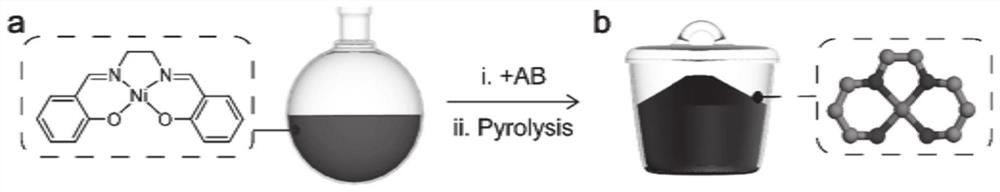

[0038] The second aspect of the present invention provides the above-mentioned MN-containing 2 o 2 The preparation method of the carbon material of unit, comprises the steps:

[0039] The precursor M-Salen and carbon materials are ball milled at a certain ratio and calcined at high temperature to obtain MN-containing 2 o 2 unit carbon material.

[0040] Among them, during the calcination process, the structure of the precursor M-Salen changes to form MN 2 o 2 units, while attached in a carbon support, forming a composite.

[0041] The carbon material in the present invention is a carbon material, without special requirements, specifically including commercial carbon materials and carbon materials prepared by conventional experimental techniques, preferably one of acetylene black, carbon black, graphene, and carbon nanotubes or more.

[0042] In the above preparation process, containing MN 2 o 2 The addition ratio of the precursor of the unit to the carbon material has...

Embodiment 1

[0055] 1) Contains NiN 2 o 2 The preparation method of the unit carbon material: 1 gram of precursor M-Salen and 1 gram of commercial acetylene black are ball-milled for 15 minutes with a ball mill, and then calcined in a tube furnace at 300 degrees Celsius with a nitrogen stream for 2 hours. After the furnace was cooled to room temperature, the obtained black powder was washed with 30% hydrogen peroxide, deionized water and absolute ethanol, and dried in a vacuum oven at 60 degrees Celsius for 12 hours to obtain a NiN-containing powder. 2 o 2 The unit carbon material has a yield of 56% to 80%.

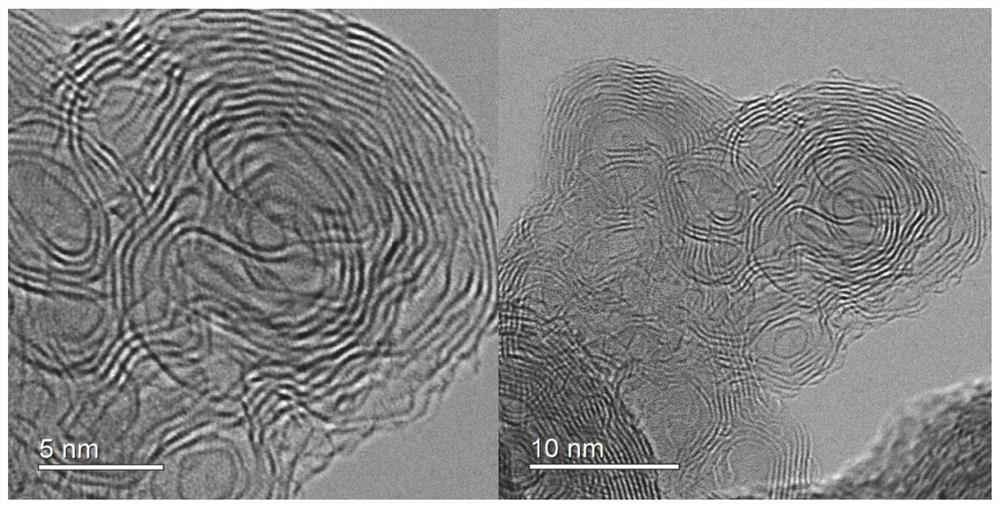

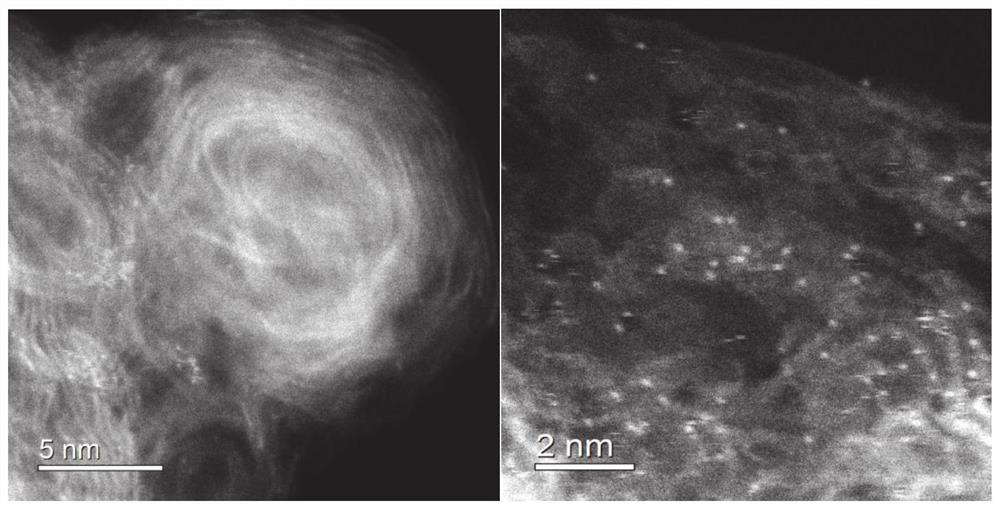

[0056] figure 2 The obtained NiN-containing 2 o 2 The high-resolution electron microscope image of the unit carbon material. It can be seen from the figure that the material presents a cloud-like morphology. image 3 It is the spherical aberration electron microscope picture of the material, and the nickel atoms dispersed in the form of single atoms can be clearly seen; Figur...

Embodiment 2

[0058] 1) Contains CuN 2 o 2 The preparation method of the unit carbon material: 1 gram of precursor Cu-Salen and 1 gram of graphene are ball-milled with a ball mill for 15 minutes, and then calcined in a tube furnace at 300 degrees Celsius with a nitrogen stream for 2 hours. After cooling to room temperature, the obtained black powder was washed with 30% hydrogen peroxide, deionized water and absolute ethanol, and dried in a vacuum oven at 60 degrees Celsius for 12 hours to obtain CuN-containing 2 o 2 The unit carbon material has a yield of 56% to 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com