Method for preparing catalytic iron oxide carbon micro-electrolysis filler through high-temperature activation method

A technology for catalyzing iron oxide carbon and high temperature activation, which is applied in chemical instruments and methods, oxidized water/sewage treatment, sterilization/microdynamic water/sewage treatment, etc. Expensive and other problems, to achieve the effect of multiple current density and electrolysis efficiency, reducing raw material cost and reducing oxygen partial pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

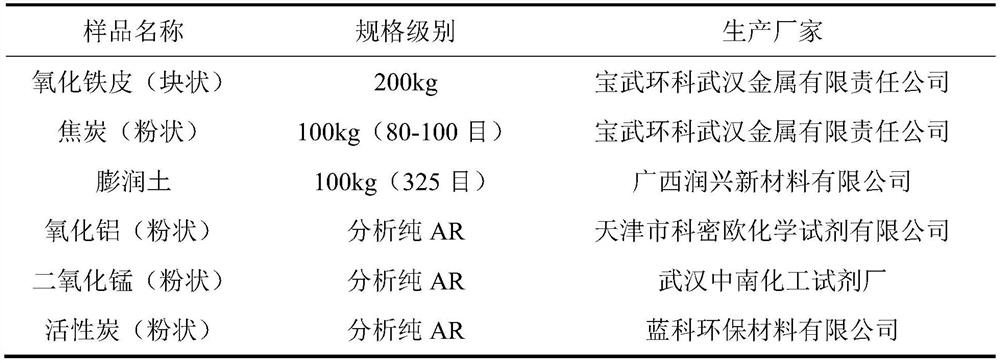

[0036] A preparation method for catalytic iron oxide carbon micro-electrolysis filler, specifically comprising the following steps:

[0037] 1) Prepare 5 kg of mixed raw materials with 70% iron oxide scale, 20% coke powder, and 6% bentonite, and add a catalyst with a total mass of 4% of the mixed raw materials; wherein, the catalyst includes alumina powder with a mass ratio of 1:1:1 , manganese dioxide powder and powdered activated carbon;

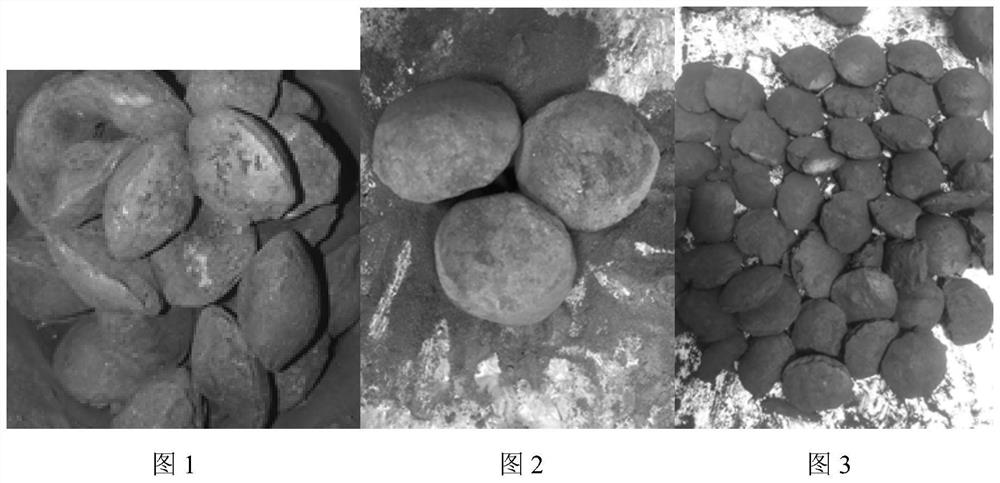

[0038] 2) Mix the mixture obtained in step 1) and ball mill for 4 hours to ensure that the materials are ball milled to 400 meshes and mixed evenly, then add water with an amount of 6% of the total mass, and press it into green pellets with a diameter of about 5 cm, such as figure 1 ;

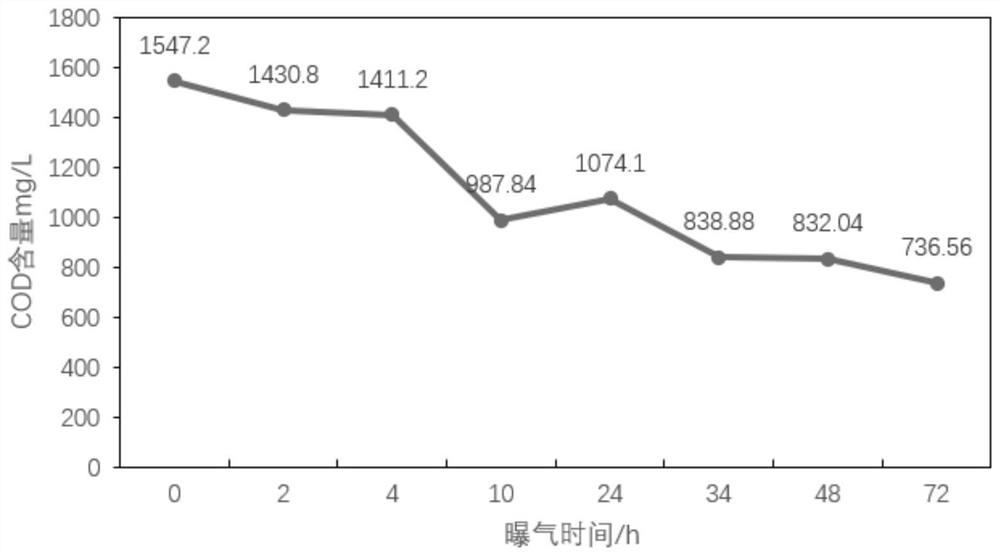

[0039]3) Dry the pellets obtained in step 2) at 110° C. for 4 hours in a constant temperature drying oven, put them into a crucible jar, coat the pellets with carbon powder (the quality of the carbon powder is 15% of the pellets) to avoid oxidation, and pu...

Embodiment 2

[0042] A preparation method for catalytic iron oxide carbon micro-electrolysis filler, specifically comprising the following steps:

[0043] 1) Prepare 5 kg of mixed raw materials with 70% iron oxide scale, 24% coke powder, and 4% bentonite, and add a catalyst with a total mass of 2% of the mixed raw materials; wherein, the catalyst includes a 1:1 mass ratio of 1:1:1 : 0.8 alumina powder, manganese dioxide powder and powdered activated carbon;

[0044] 2) Mix the mixture obtained in step 1) and ball mill for 4 hours to ensure that the material is ball milled to 400 mesh and mixed evenly, then add water with an amount of 8% of the total mass, and press it into green pellets with a diameter of about 5 cm;

[0045] 3) Dry the pellets obtained in step 2) at 110° C. for 6 hours in a constant temperature drying oven, put them into a crucible jar, coat the pellets with carbon powder (the quality of the carbon powder is 15% of the pellets) to avoid oxidation, and put Put it into a hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com