High-strength high-temperature-resistant MDI-based slow-rebound polyurethane sponge material and preparation method thereof

A polyurethane sponge, high temperature resistant technology, applied in the field of organic polymer synthesis, can solve the problems of poor combination of inorganic filler and polymer matrix, inorganic filler, influence and other problems, and achieve the effect of excellent thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

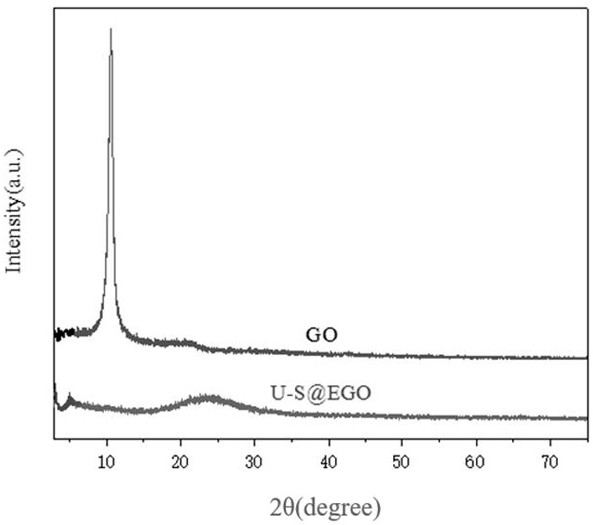

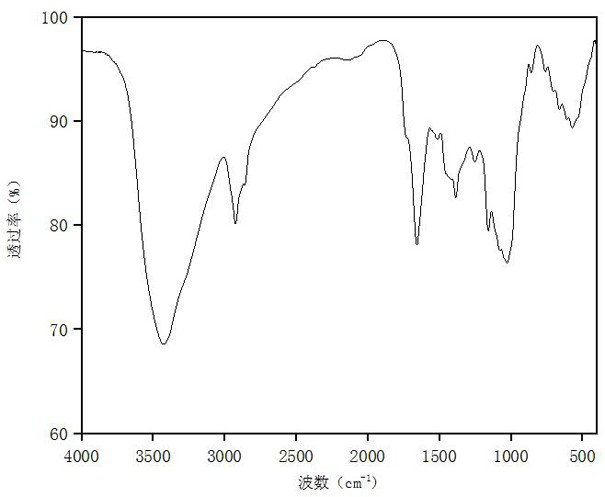

[0037](1) Preparation of expanded urethane-silica functionalized graphene oxide U-S@EGO:

[0038] First, 1 g expanded graphite (EG), 0.5 g NaNO 3 Add it into a 250 mL round bottom flask, then pour 70 mL of 95wt% concentrated sulfuric acid into it, stir it magnetically for 10 min at a temperature of 4°C, then slowly add 3 g of potassium permanganate (0.5 g every 5 min, and complete the addition in 30 min ), and continued to stir for 8 h after the addition. Then add 50 mL of deionized water, followed by 20 mL of 5wt% H 2 o 2 The solution was oxidized and stirred for 1 h. The mixture was centrifuged, vacuum-filtered with a 0.45 μm filter membrane, washed until neutral, and dried in a blast drying oven at 100°C for 12 h to obtain EGO;

[0039] Add 0.2 g of expanded graphene oxide (EGO) into a beaker filled with 100 mL of anhydrous N,N-dimethylformamide, place it in an ultrasonic cleaner for ultrasonic dispersion for 1 h, and transfer it to a 250 mL beaker filled with nitrogen ...

Embodiment 2

[0050] (1) Preparation of expanded urethane-silica functionalized graphene oxide U-S@EGO: Same as Example 1,

[0051] (2) Preparation of Phosphorylated Corn Starch Modified Wheat Bran Fiber CSP@WBF: Same as Example 1,

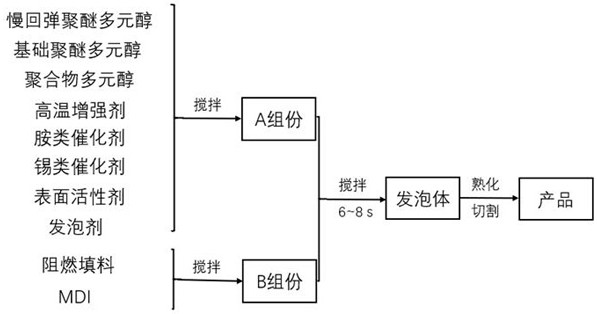

[0052] (3) Preparation of high-strength and high-temperature-resistant MDI-based slow-rebound polyurethane sponge:

[0053] Weigh the following raw materials in parts by weight: DALTOPED ® 40 parts of AQUAPUR, 40 parts of PPG3000, 20 parts of POP-3630, 5 parts of U-S@EGO, 1.4 parts of BL-11, 0.5 parts of T-12, 1.1 parts of L-3002, 1.5 parts of deionized water, 1 part of CSP@WBF, MDI 60 copies;

[0054] will DALTOPED ® Add AQUAPUR, PPG3000, and POP-3630 into the container in proportion, then add U-S@EGO, BL-11, T-12, L-3002, and deionized water according to the formula, and stir for 60 seconds under the mixer with a speed of 1500, record For A component;

[0055] Weigh CSP@WBF and MDI into another container and stir for 30 seconds under a mixer with a rotat...

Embodiment 3

[0058] (1) Preparation of expanded urethane-silica functionalized graphene oxide U-S@EGO: Same as Example 1,

[0059] (2) Preparation of Phosphorylated Corn Starch Modified Wheat Bran Fiber CSP@WBF: Same as Example 1,

[0060] (3) Preparation of high-strength and high-temperature-resistant MDI-based slow-rebound polyurethane sponge:

[0061] Weigh the following raw materials in parts by weight: DALTOPED ® 40 parts of AQUAPUR, 40 parts of PPG3000, 20 parts of POP-3630, 1 part of U-S@EGO, 1.4 parts of BL-11, 0.5 parts of T-12, 1.1 parts of L-3002, 1.5 parts of deionized water, 5 parts of CSP@WBF, MDI 60 copies;

[0062] will DALTOPED ® Add AQUAPUR, PPG3000, and POP-3630 into the container in proportion, then add U-S@EGO, BL-11, T-12, L-3002, and deionized water according to the formula, and stir for 60 seconds under the mixer with a speed of 1500, record For A component;

[0063] Weigh CSP@WBF and MDI into another container and stir for 30 seconds under a mixer with a rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com