Alkynyl carbon material, preparation method thereof and composite electrode

A composite electrode and carbon material technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, circuits, etc., can solve the problems of increased synthesis cost of alkyne-based carbon materials, low yield and purity of alkyne-based carbon, and complicated reaction process. Achieve the effects of improved purity, simple process, and mild operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

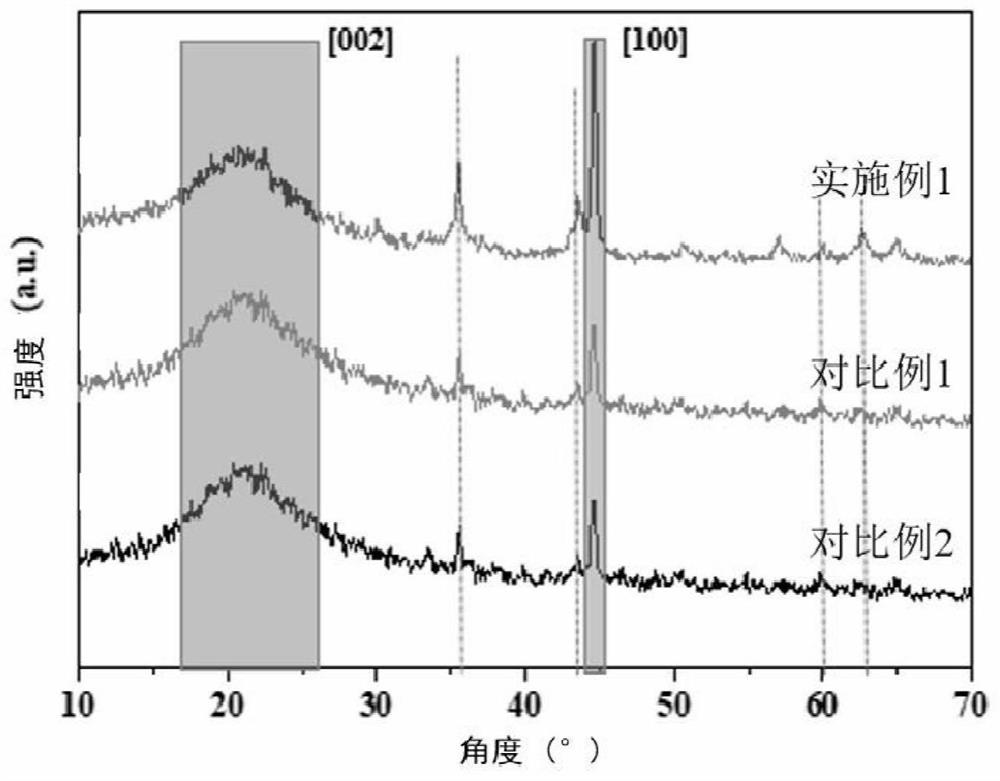

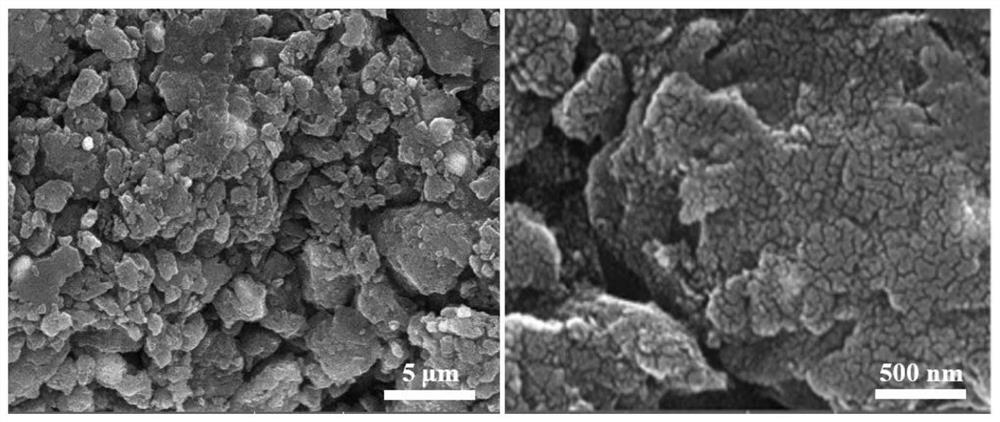

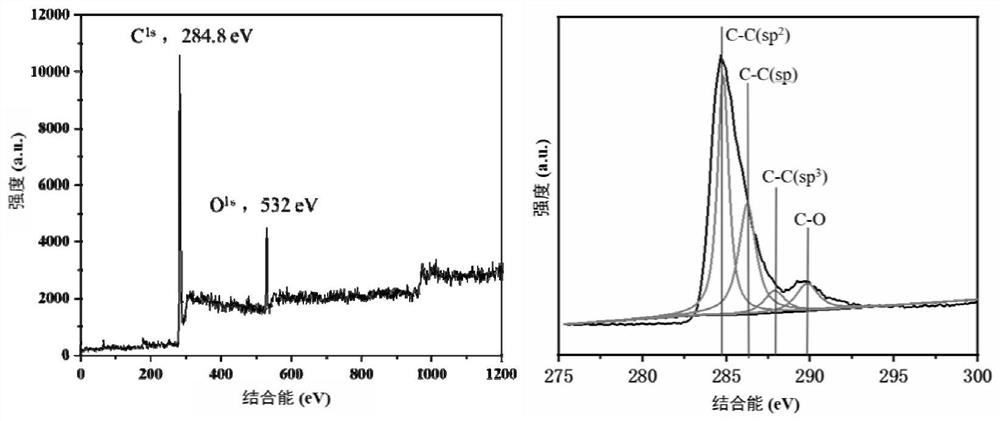

Embodiment 1

[0040] 1) Calcium carbide and hexabromobenzene after vacuum drying are mixed in a molar ratio of 5:1, the mass ratio of stainless steel grinding balls to the total mass of calcium carbide and hexabromobenzene is 10:1, grinding balls of different diameters (5mm, 8mm, 10mm, 12mm, 15mm) ratio 5:4:3:2:1, mix and seal the ball milling tank in a glove box filled with argon atmosphere protection;

[0041] 2) Using a planetary ball mill to mill for 24 hours at a rate of 1000r / min, pass through a 140-mesh sieve to obtain a mixed product;

[0042] 3) Wash the screened sample with 0.5mol / L dilute nitric acid solution several times until the eluate is neutral, then filter and dry, weigh 3g of the sample and place it in a porcelain boat in a nitrogen atmosphere. In a protected tube furnace, the temperature was raised to 300° C. for 5 hours at a heating rate of 2° C. / min for calcination, and naturally cooled to room temperature to obtain an alkyne-based carbon material.

Embodiment 2

[0044] The ratio of grinding balls with different diameters (5, 8, 10, 12, 15 mm) is 2:1:3:5:4, and the rest are the same as in Example 1.

Embodiment 3

[0046] The ratio of grinding balls with different diameters (5, 8, 10, 12, 15 mm) is 1:3:5:2:4, and the rest are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com