Preparation method of copper-cobalt oxygen evolution catalyst

A catalyst and oxygen evolution technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of low electrolysis efficiency, slow response, high internal resistance, etc., and achieve the effect of reducing energy consumption, long life and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

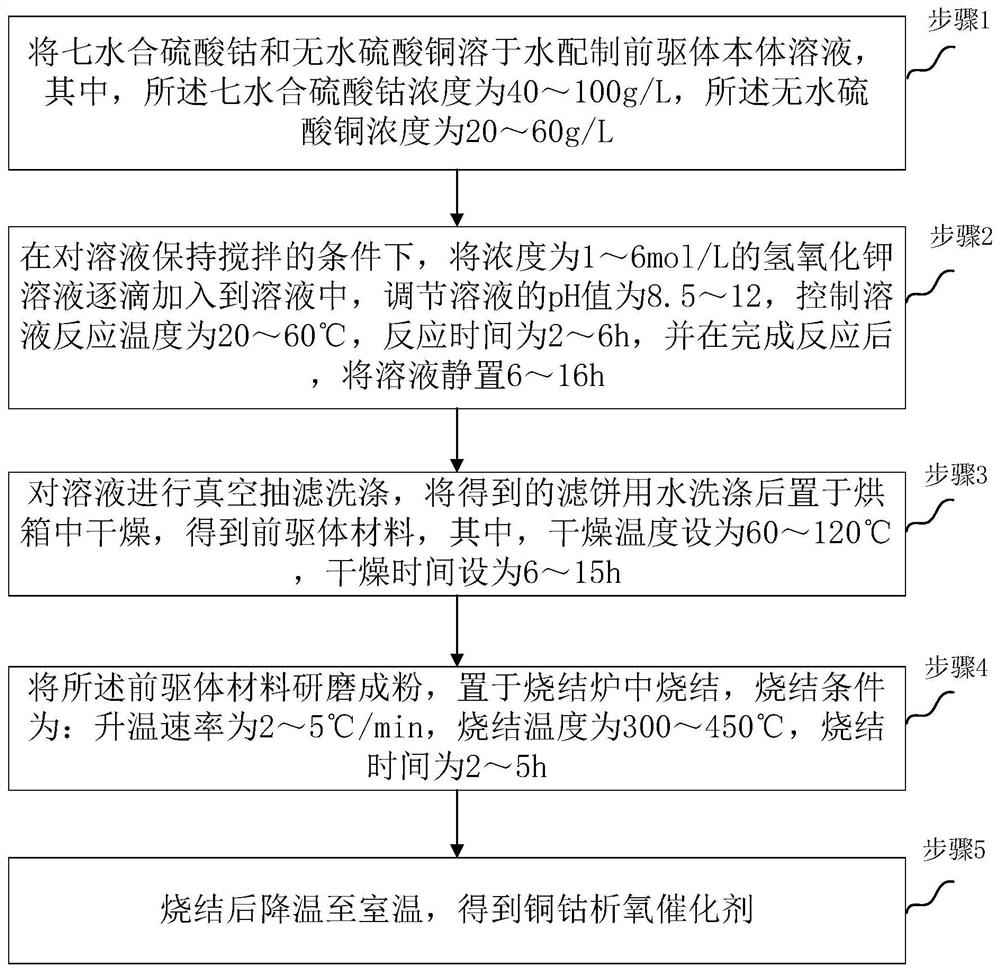

[0031] The embodiment of the present invention provides a kind of preparation method of copper-cobalt oxygen evolution catalyst, such as Figure 1 to Figure 6 shown, including the following steps:

[0032] Step 1: Dissolving cobalt sulfate heptahydrate and anhydrous copper sulfate in water to prepare a precursor bulk solution, wherein the concentration of cobalt sulfate heptahydrate is 40-100 g / L, and the concentration of anhydrous copper sulfate is 20-60 g / L L;

[0033] Step 2: Under the condition of keeping stirring the solution, add potassium hydroxide solution with a concentration of 1-6 mol / L into the solution drop by drop, adjust the pH value of the solution to 8.5-12, and control the reaction temperature of the solution to 20-60 °C, the reaction time is 2-6 hours, and after the reaction is completed, the solution is allowed to stand for 6-16 hours;

[0034] Step 3: vacuum filter and wash the solution, wash the obtained filter cake with water and dry it in an oven to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com