Formula, preparation method and use method of compound low-sodium-salt sauced beef cooking liquid

A technology for compounding low-sodium salt and sauce beef, which is applied in the directions of food ingredients, application, and chemical preservation of meat/fish containing inorganic compounds, can solve the problems of affecting the taste of low-sodium salt, popularization and application, and aggravating bitterness, etc. The effect of inhibiting the production and reproduction of pathogenic bacteria, improving flavor, and enhancing flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the compound low-sodium-salt sauce beef cooking solution: add potassium chloride, calcium chloride, calcium ascorbate, and sodium chloride into water, stir and dissolve at 40-50° C., and then add basic amino acid, glycyrrhizic acid, yellow bean Raw gum, yeast extract powder, meat tenderizer, and cooking wine are stirred evenly and set aside for later use to prepare the compound low-sodium sauce beef cooking liquid.

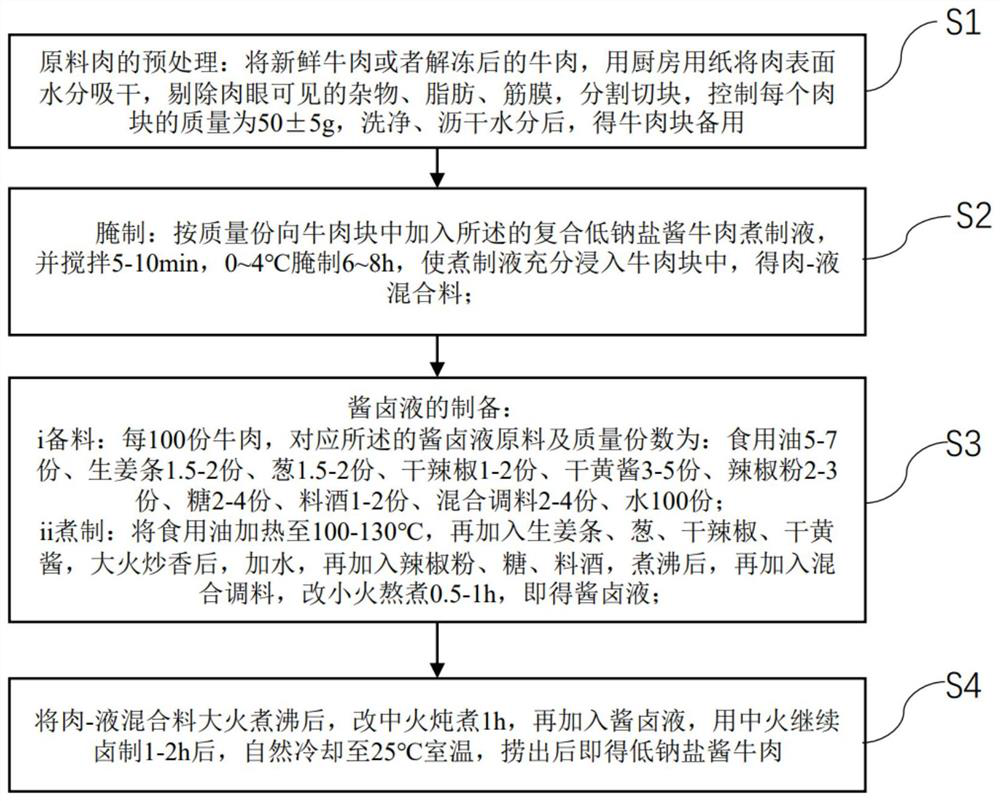

[0029] The method for using the compound low-sodium-salt sauce beef cooking liquid is to prepare the low-sodium-salt sauce beef by cooperating with the sauce brine, which specifically includes the following steps:

[0030] (1) Pretreatment of raw meat: Blot fresh beef or thawed beef with kitchen paper to dry the surface of the meat, remove visible debris, fat, fascia, divide and cut into pieces, and control each piece of meat The quality of the meat is 50 ± 5g, after washing and draining, the beef cubes are obtained for later use; ...

Embodiment 1

[0041] A. Preparation of compound low-sodium sauce beef cooking liquid:

[0042] (1) Mix aspergillus oryzae protease, papain and tapioca starch according to the mass ratio of 1:2:50 to obtain meat tenderizer;

[0043] (2) Add 1.5g potassium chloride, 1.5g calcium chloride, 0.6g calcium ascorbate, 7.5g sodium chloride into 600g water, stir and dissolve at 40°C, then add 1.2g lysine, 0.6g glycyrrhizic acid, 0.9 g xanthan gum, 1.5g yeast extract powder, 3g meat tenderizer, 4.5g cooking wine, after stirring evenly, set aside for later use to prepare a compound low-sodium sauce beef cooking liquid;

[0044] B. Prepare low-sodium beef sauce:

[0045] (1) Pretreatment of raw meat: Select 300g of fresh beef, use kitchen paper to dry the surface of the meat, remove the sundries, fat, and fascia visible to the naked eye, divide and cut into pieces, and control the quality of each piece of meat to 50 ±5g, after washing and draining the water, get the beef cubes for later use;

[0046]...

Embodiment 2

[0051] A. Preparation of compound low-sodium sauce beef cooking liquid:

[0052] (1) Mix Aspergillus oryzae protease, papain and tapioca starch according to the mass ratio of 1:2.5:50 to obtain meat tenderizer;

[0053] (2) Add 4g of potassium chloride, 3.5g of calcium chloride, 1.8g of calcium ascorbate, and 9g of sodium chloride into 600g of water, stir and dissolve at 45°C, then add 2.4g of lysine, 1.8g of glycyrrhizic acid, and 1.2g of yellow Raw gum, 1.8g yeast extract powder, 4.5g meat tenderizer, 5g cooking wine, after being stirred evenly, set aside for later use to prepare a compound low-sodium sauce beef cooking liquid;

[0054] B. Prepare low-sodium beef sauce:

[0055] (1) Pretreatment of raw meat: Select 300g of fresh beef, use kitchen paper to dry the surface of the meat, remove the sundries, fat, and fascia visible to the naked eye, divide and cut into pieces, and control the quality of each piece of meat to 50 ±5g, after washing and draining the water, get th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com