Method for regenerating coking catalyst

A catalyst and coking technology, applied in the direction of catalyst regeneration/reactivation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of high energy consumption and operating costs, improve recycling efficiency, prevent tail burning, regeneration the effect of safe operation of the

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

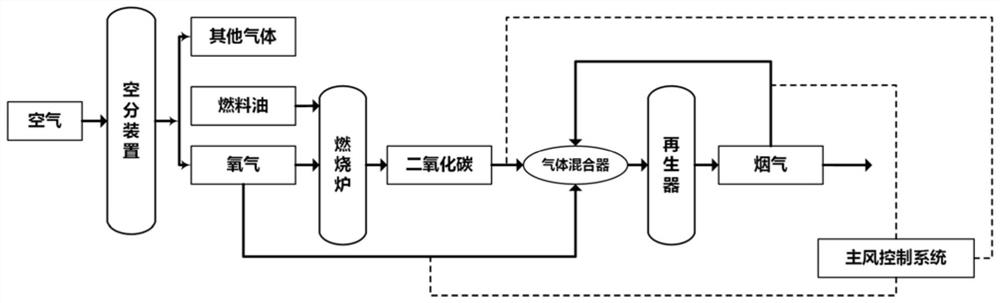

[0044] like figure 1 As shown, in the start of the catalytic cracking device, the components of the air are separated by the space separation device, separating high purity oxygen and other gases; positively passing high purity oxygen into the combustion furnace, contacting the fuel oil High purity carbon dioxide; after mixing the resulting high purity carbon dioxide with high purity oxygen at 4: 1, after mixing in the mixer, instead of the main wind, enter the catalytic cracking regenerator to promote the burn to the standby agent The focus reaction produces a regenerative flue gas of high carbon dioxide content; the recycled flue gas discharged from the regeneration system is under the control of the main wind control system, and the mixer is circulated back into the mixer, and gradually replaces the carbon dioxide generated by the combustion furnace. Initial operating conditions of the regenerator are shown in Table 1, the regeneration flue gas composition is shown in Table 2. ...

Embodiment 2

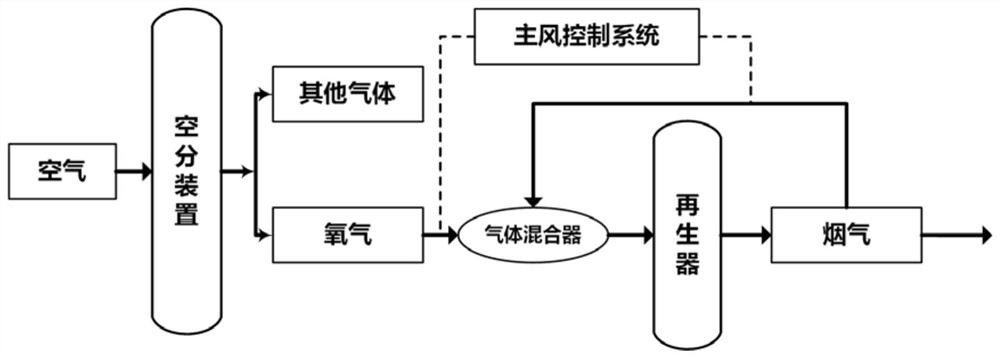

[0046] like figure 2 As shown, in the stable operating stage of the catalytic cracking device, the components of the air are separated by the space separation device, separating high purity oxygen and other gases; at the control system of the main control system, high purity oxygen and part Regenerator smoke (mainly CO 2 The molar ratio of 1: 5 is mixed in the mixer, and the catalytic cracking regenerator is transferred to the firing reaction, and the carbon dioxide content is high. Initial operating conditions of the regenerator are shown in Table 1, the regeneration flue gas composition is shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com