Multi-component rare earth modification technical method applied to polypropylene-based material

A polypropylene-based, rare-earth modification technology, applied in the field of polypropylene modification, can solve the problems of reduced activity, easy volatilization, poor performance of polypropylene-based materials, etc., to ensure activity, improve heat resistance and stability, The effect of anti-oxidation performance and anti-ultraviolet performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

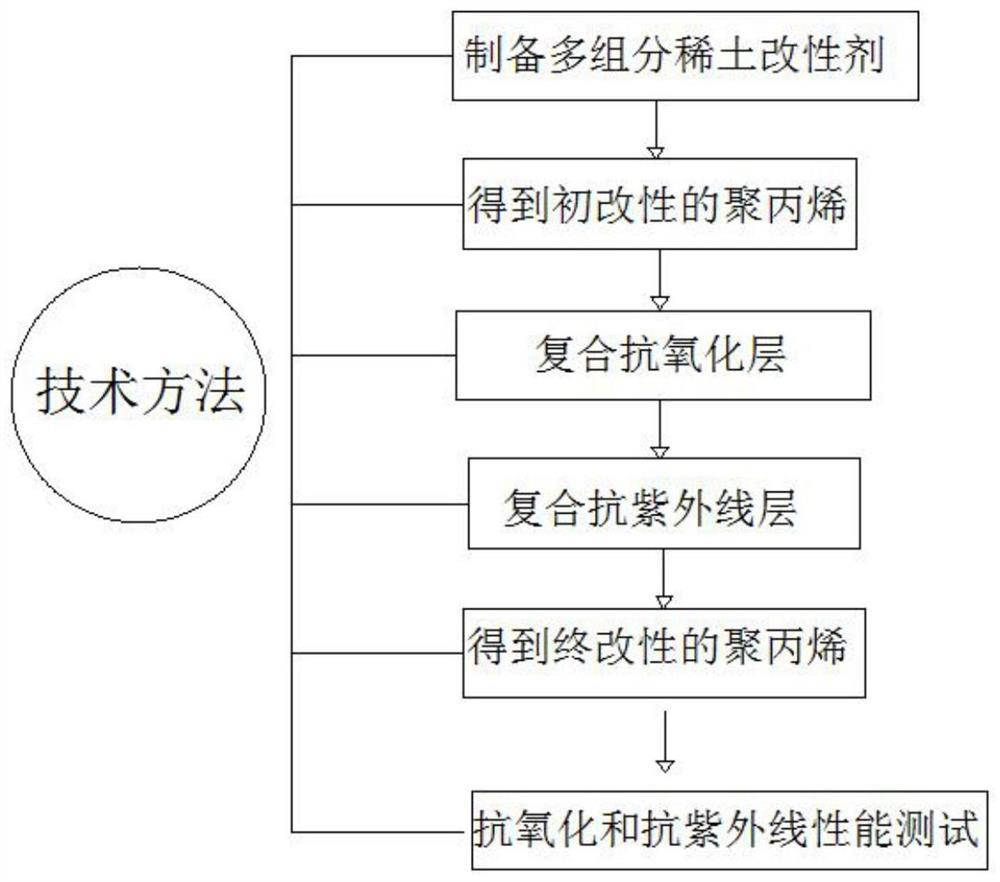

[0026] Embodiment 1, with reference to figure 1 , a multi-component rare earth modification technology method applied in polypropylene-based materials, comprising the following steps:

[0027] S1: Pour 500g of lanthanum oxide powder into an intelligent temperature-controlled magnetic stirrer for full stirring. During the stirring process, add 30ml of diethylhydroxylamine stabilizer, 20ml of silane coupling agent and 10ml of N-phenylmaleimide Heat-resistant agent, stir for 30min-45min at a temperature of 85°C-100°C, after the stirring is completed, take out the mixed solution and let it stand for 15min before fully drying, and finally obtain a multi-component rare earth modifier;

[0028] S2: The polypropylene-based material is polymerized to obtain a polypropylene polymer, and then calcium carbonate and silicon dioxide with a mass fraction ratio of 2:5 are filled into the polypropylene polymer, and then the multi-component obtained in S1 The rare earth modifier is added and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com