Polymer-based high-thermal-conductivity material and preparation process thereof

A preparation process and high thermal conductivity technology, applied in the direction of heat exchange materials, circuit substrate materials, circuit heat devices, etc., can solve the problem that the thermal conductivity cannot be further improved, achieve good regularity, improve thermal conductivity, and save costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

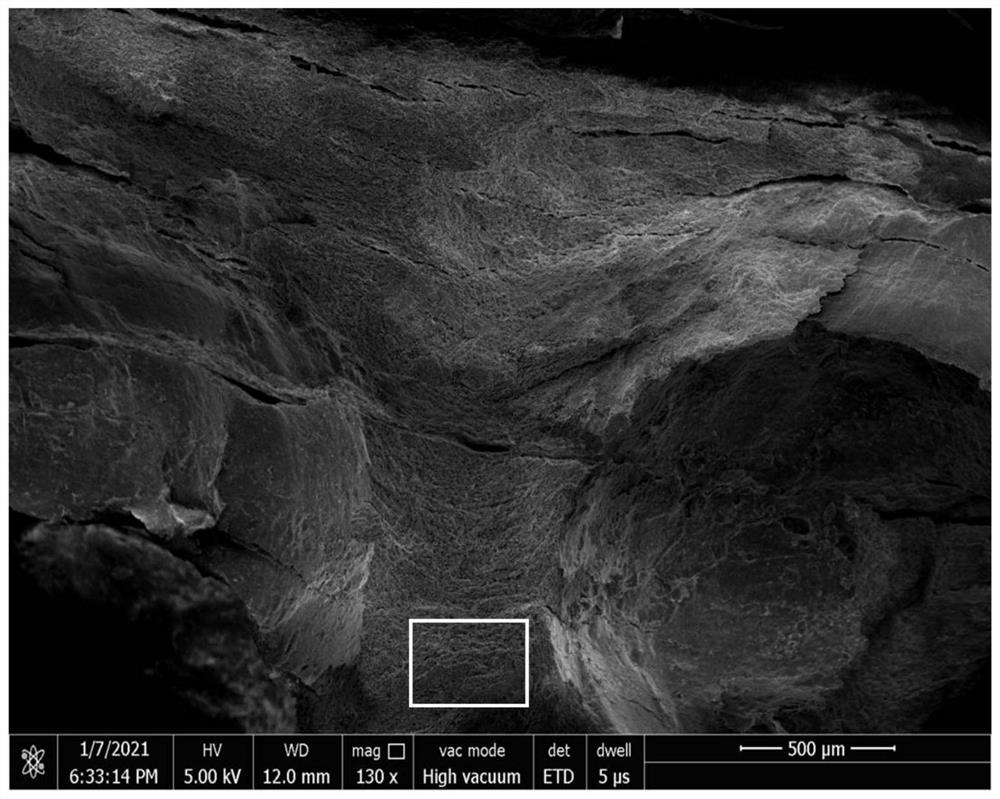

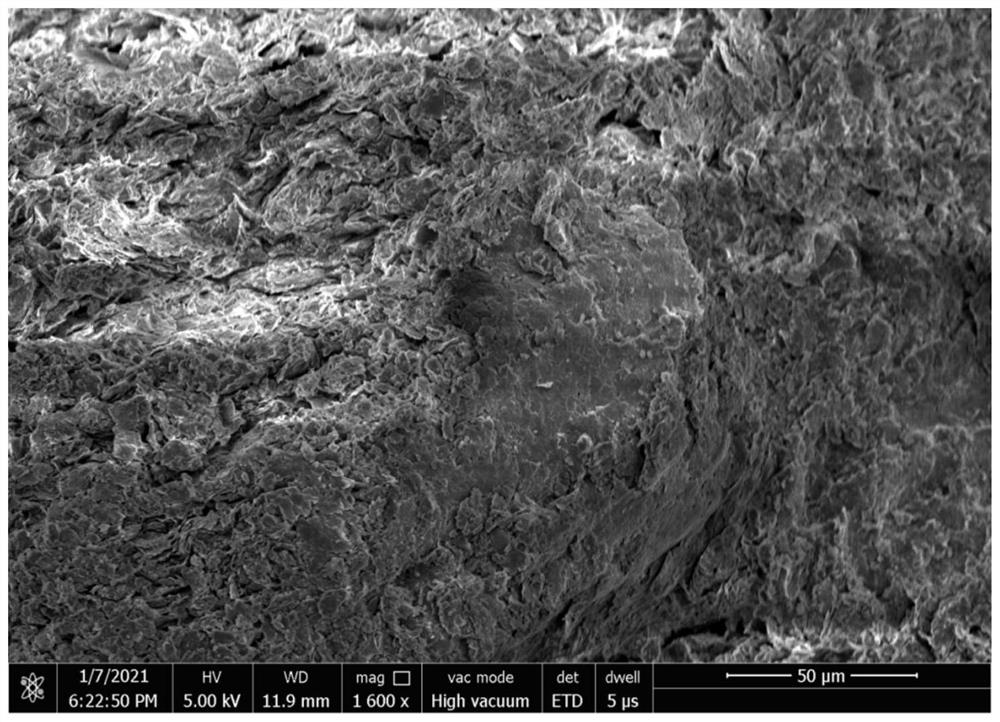

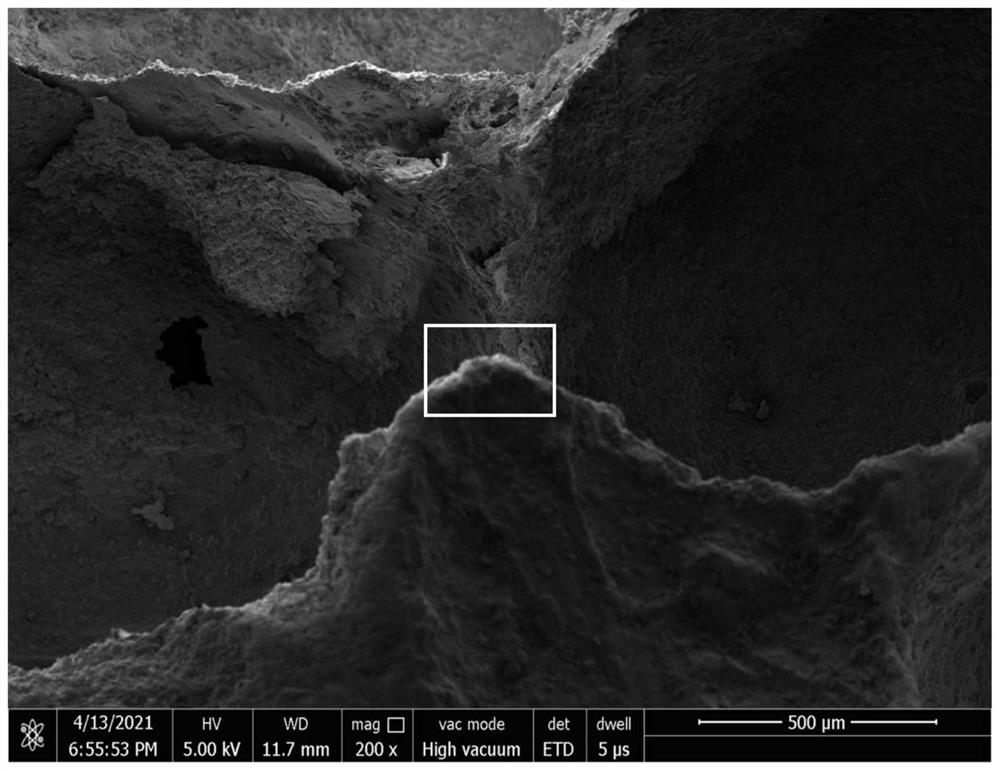

Image

Examples

Embodiment 1

[0060] A preparation process for a polymer-based high thermal conductivity material, comprising the steps of:

[0061] (1) In terms of parts by volume, take 10 parts of thermally conductive filler (boron nitride, BN) and 90 parts of pore-forming agent (select urea), mix the thermally conductive filler and pore-forming agent evenly to obtain a mixture, and then place In the mold, compression molding (pressure 200MPa, time 5 minutes), heating up for heat treatment (temperature 140°C, time 2 hours) to obtain a thermally conductive skeleton;

[0062] (2) According to the number of parts by mass, take 75 parts of resin (select epoxy resin 5015) and 25 parts of curing agent (select epoxy resin curing agent 5015), mix the resin and curing agent evenly (stir and mix evenly, and the stirring time is 5 minutes), obtain mixed solution (epoxy resin prepolymer);

[0063] (3) Soak the heat-conducting skeleton described in step (1) in the mixed liquid described in step (2) in the container,...

Embodiment 2

[0065] A preparation process for a polymer-based high thermal conductivity material, comprising the steps of:

[0066] (1) In terms of parts by volume, take 20 parts of thermally conductive filler (boron nitride, BN) and 80 parts of pore-forming agent (select urea), mix the thermally conductive filler and pore-forming agent evenly to obtain a mixture, and then place In the mold, compression molding (pressure 200MPa, time 5 minutes), heating up for heat treatment (temperature 140°C, time 2 hours) to obtain a thermally conductive skeleton;

[0067] (2) According to the number of parts by mass, take 75 parts of resin (select epoxy resin 5015) and 25 parts of curing agent (select epoxy resin curing agent 5015), stir and mix the resin and curing agent evenly, and the stirring time is 5 minutes. Obtain mixed solution (epoxy resin prepolymer);

[0068] (3) Soak the heat-conducting skeleton described in step (1) in the mixed liquid described in step (2) in the container, the volume r...

Embodiment 3

[0070] A preparation process for a polymer-based high thermal conductivity material, comprising the steps of:

[0071] (1) In terms of parts by volume, take 30 parts of thermally conductive filler (boron nitride, BN) and 70 parts of pore-forming agent (select urea), mix the thermally conductive filler and pore-forming agent evenly to obtain a mixture, and then place In the mold, compression molding (pressure 200MPa, time 5 minutes), heating up for heat treatment (temperature 140°C, time 2 hours) to obtain a thermally conductive skeleton;

[0072] (2) According to the number of parts by mass, take 75 parts of resin (select epoxy resin 5015) and 25 parts of curing agent (select epoxy resin curing agent 5015), stir and mix the resin and curing agent evenly, and the stirring time is 5 minutes. Obtain mixed solution (epoxy resin prepolymer);

[0073] (3) Soak the heat-conducting skeleton described in step (1) in the mixed liquid described in step (2) in the container, the volume r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductance | aaaaa | aaaaa |

| thermal conductance | aaaaa | aaaaa |

| thermal conductance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com