Treatment method for realizing high-mixing-amount and high-quality recycling of RAP

A treatment method and high-quality technology, applied in roads, construction, road repair, etc., can solve problems such as low enthusiasm, high requirements for the site area of the mixing station, and increased workload of the construction party, so as to improve efficiency and quality, and facilitate On-site construction, the effect of reducing management difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

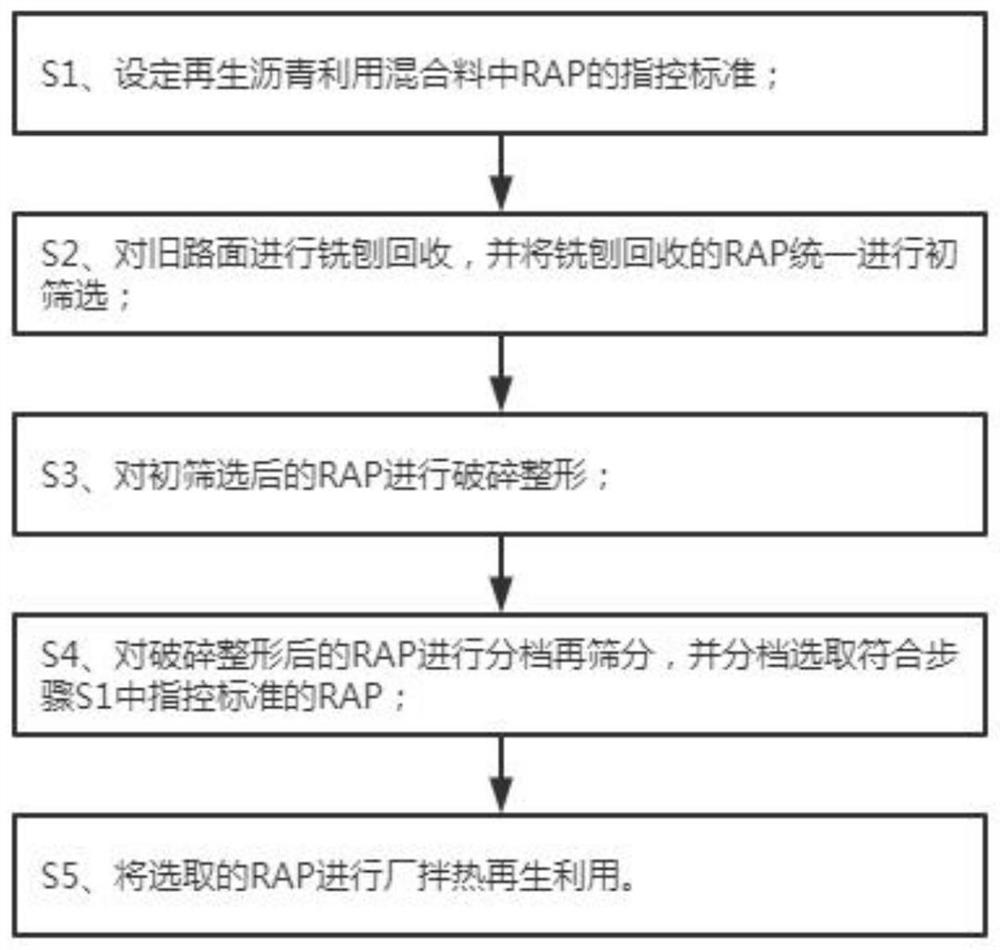

[0027] Please refer to figure 1 Shown, the present invention discloses a kind of processing method that realizes RAP large dosage high-quality recycling, comprises the following steps:

[0028] S1. Set the charging standard for RAP in the recycled asphalt utilization mixture;

[0029] S2. Carry out milling and planing recovery of the old road surface, and uniformly stack the RAP recovered by milling and planing, and use a 10mm vibrating screen for preliminary screening, and select RAP with a size of more than 10mm;

[0030] S3. Crushing and shaping the RAP after primary screening, reducing the agglomeration of RAP coarse aggregate, playing the role of factory disposal, and promoting the consistent performance of old road materials;

[0031] S4. Classifying and re-screening the RAPs after crushing and reshaping, and selecting RAPs that meet the accusation standard in step S1 by classifying;

[0032] In the classification and re-screening, according to the type of RAP and the ...

example 1

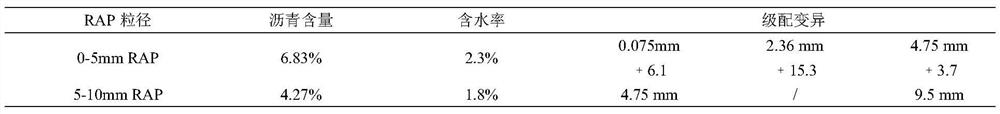

[0040] By sampling the typical AC-20 asphalt mixture milling material in the middle surface layer of the old highway road, the asphalt content, moisture content and gradation change detection are carried out. The average value of each index data is obtained from 5 groups of detection data, as shown in the following table:

[0041]

[0042]

[0043] "﹢" in the above table indicates that the sieve pass rate of the actual gradation of extraction is greater than the corresponding sieve pass rate of RAP.

[0044] The RAP test data of the road section in the table above shows that:

[0045] The RAP coarse aggregate (grain size greater than 5mm) after sieving is mainly the large-grained mineral material in various asphalt mixtures on the original pavement and the "agglomerate" structure of asphalt mortar, and a small proportion is full fine aggregate. RAP coarse aggregate generally has the characteristics of a large total proportion, mainly stone, low content of old asphalt, an...

example 2

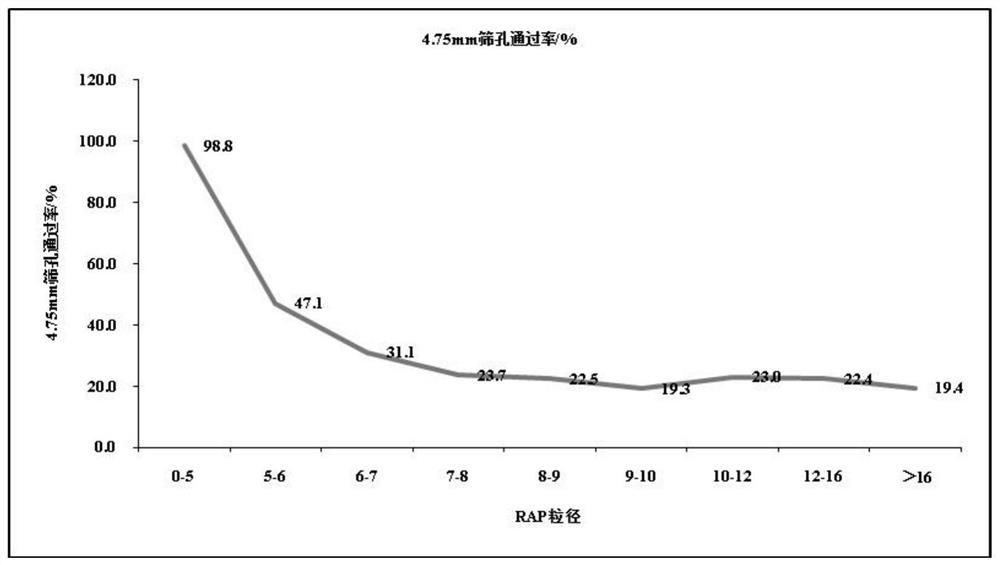

[0048]Select the RAP material for milling and planing in a certain base, and use a non-standard sieve to divide the RAP into 0-5mm, 5-6mm, 6-7mm, 7-8mm, 8-9mm, 9-10mm, 10-12mm, 12-16mm and > 16mm and other particle size specifications, and then the bitumen content of RAP with different particle size specifications was tested by combustion method, and the mineral material after RAP combustion was screened. The test results are shown in Table 3. It can be seen from Table 3 that the content of old asphalt in RAP coarse aggregate over 5 mm is significantly lower than that of 0-5 mm RAP asphalt, estimated at 50% dosage, the proportion of old asphalt in the total asphalt in the recycled asphalt mixture prepared with RAP over 5 mm is not more than 30%, which greatly reduces the difficulty of regeneration of old asphalt. The binder in the recycled asphalt mixture is mainly the new asphalt added. The performance of the recycled asphalt mixture is dominated by the addition of new asphalt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com