A surface pretreatment process of diamond-like coating workpiece

A workpiece surface, diamond technology, applied in metal material coating process, sputtering plating, ion implantation plating, etc., can solve the problems of affecting the coating performance parameters, polluting the tank, scrapping the workpiece, etc., to improve the combination of coating and coating The effect of improving the cleaning effect and reducing the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

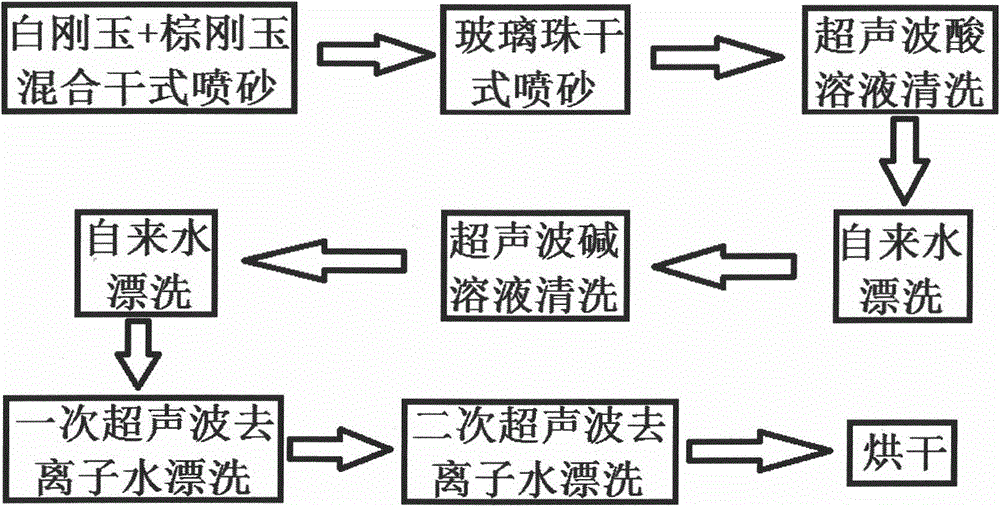

[0043] A diamond-like coating workpiece surface pretreatment process, the block diagram of the process flow is as follows figure 1 As shown, the specific steps of the process are as follows:

[0044] (1) white corundum + brown corundum mixed dry sandblasting

[0045] In white corundum + brown corundum mixed dry sandblasting, the particle size of white corundum and brown corundum are both 120 mesh, the mass ratio of white corundum to brown corundum is 7:3, the distance between the spray gun nozzle and the workpiece surface: 5-10cm; sandblasting pressure: 0.6MPa; sandblasting angle: 60-90° to the working surface; sandblasting times: 2 times on the front and back sides; in order to improve the sandblasting effect and efficiency, the spray gun is required to swing slightly during work; nitrogen is used at the end of sandblasting Clean the sand on the surface of the workpiece.

[0046] (2) Dry sandblasting with glass beads

[0047] The particle size of glass beads used in dry sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com