Thermosensitive resistor, chip material and preparation method thereof

A technology for thermistors and chip materials, applied in thermistors, manufacturing resistor chips, resistors, etc., to achieve high precision and improve compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

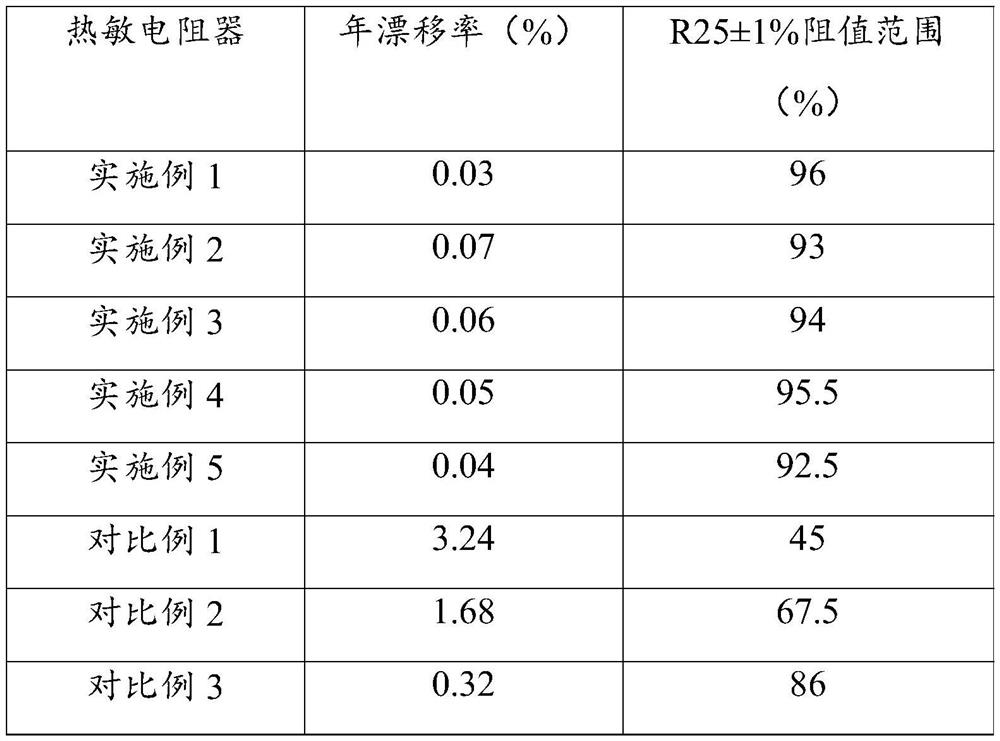

Examples

preparation example Construction

[0021] This specific embodiment also proposes the preparation method of above-mentioned chip material, comprises the following steps:

[0022] S1. Mix the components according to the ratio and ball mill at a speed of 240-250 cycles / min for 8-9 hours to obtain the first mixture; ball mill to mix the various raw materials evenly;

[0023] S2. Dry the first mixture at 100-120°C, then heat up to 500-600°C for the first calcination for 2-3 hours, then continue to heat up to 900-1000°C for the second calcination for 1-1.5 hours, then lower the temperature to 500-600°C for 2-3 hours, then cut off the power and cool down to obtain the second mixture;

[0024] S3. The second mixture is made into an intermediate by a wet casting process; specifically, the wet casting process includes: adding PVA glue to the second mixture, forming a slurry after stirring, and using a casting machine Casting 2-3 times to obtain the rubber block, cutting the prepared rubber block into 15cm×15cm squares, ...

Embodiment 1

[0029] This embodiment proposes a chip material, which includes: 40% of manganese tetraoxide; 37% of tricobalt tetroxide; 15% of aluminum oxide; 8% of chromium oxide, 100% in total.

[0030] This embodiment also proposes the preparation method of the chip material, comprising the following steps:

[0031] S1. Mix the components according to the ratio and ball mill at a speed of 240 cycles / min for 9 hours to obtain the first mixture;

[0032] S2. Dry the first mixture at 100°C, then raise the temperature to 500°C for the first calcination for 2 hours, then continue to raise the temperature to 900°C for the second calcination for 1 hour, then lower the temperature to 500°C and keep it for 2 hours , then turn off the power and cool down to obtain the second mixture; in this step, the heating rate is 10°C / min, and the cooling rate is 5°C / min;

[0033] S3. The second mixture is made into an intermediate by a wet casting process; specifically, the wet casting process includes: addi...

Embodiment 2

[0036] This embodiment proposes a chip material, which includes: 50% manganese tetraoxide; 30% cobalt tetroxide; 18% aluminum oxide; 2% chromium oxide, 100% in total.

[0037] This embodiment also proposes the preparation method of the chip material, comprising the following steps:

[0038] S1. Mix the components according to the ratio and ball mill at a speed of 250 cycles / min for 8.5 hours to obtain the first mixture;

[0039] S2. Dry the first mixture at 110°C, then raise the temperature to 600°C for the first calcination for 3 hours, then continue to raise the temperature to 950°C for the second calcination for 1.5 hours, then lower the temperature to 600°C and keep it for 3 hours , then turn off the power and cool down to obtain the second mixture; in this step, the heating rate is 5°C / min, and the cooling rate is 8°C / min;

[0040] S3. The second mixture is made into an intermediate by a wet casting process; specifically, the wet casting process includes: adding PVA glue...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com