Method for preparing porous carbon fiber-based catalyst by desublimation compounding of metal oxide in carbonization process

A technology of porous carbon fiber and carbonization process, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical/physical process, etc. Oxide addition is limited, affecting carbon fiber support strength and other issues, to achieve the effect of reducing production cost, improving carbonization efficiency, and improving catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

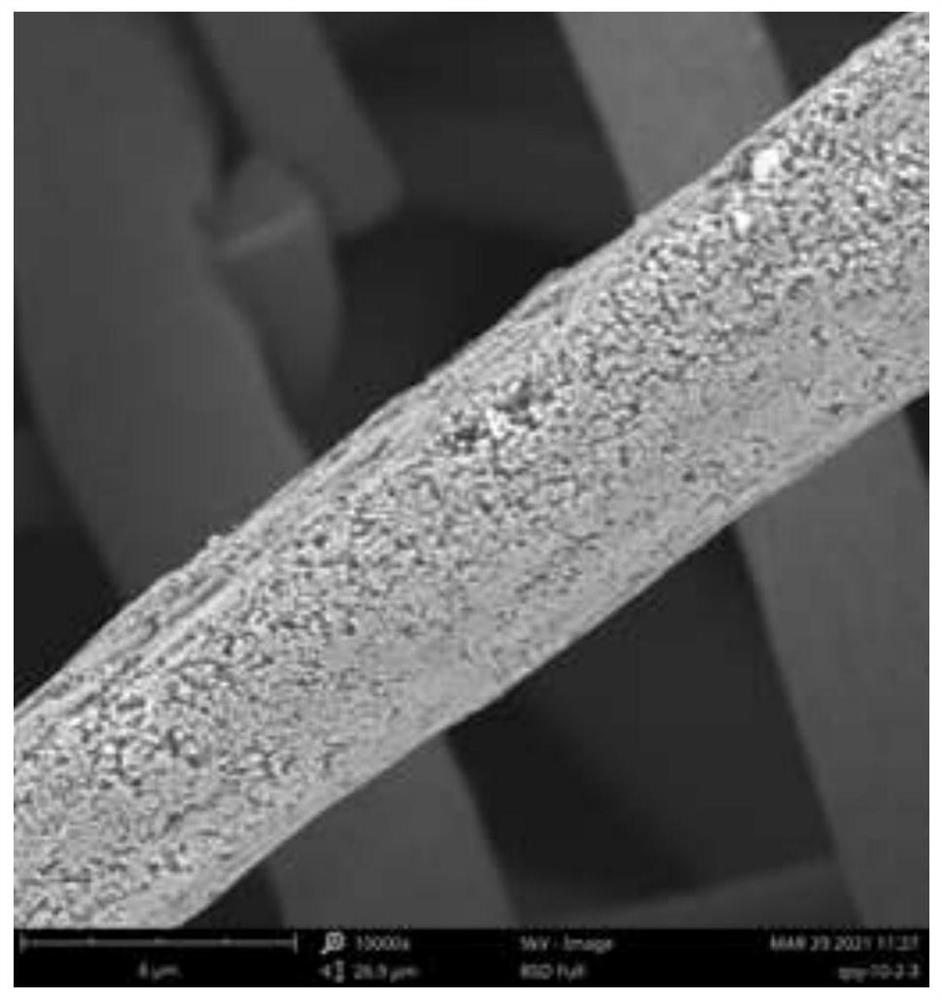

[0041]In step S1, the preparation method of the porous polymer fiber net includes: mixing a polymer spinning solution with a mass fraction of 10-17% and a porogen of 10-17% for centrifugal spinning, and collecting the net into a web , to obtain the porous polymer fiber web.

[0042] The rotational speed of the centrifugal spinning is 2000-8000r / min, the spinneret aperture is 0.1-1mm, the spinning temperature is 20-80°C, and the collection distance is 1-15cm.

[0043] The porous polymer fiber web is polyacrylonitrile-based fiber web, lignin-based fiber web, polyimide-based fiber web or pitch-based fiber web; preferably polyacrylonitrile fiber web. The porogen is polyethylene glycol, polyvinylpyrrolidone, polyvinyl butyral or polyvinyl alcohol. By adding a porogen, it decomposes under high temperature conditions, thereby forming a porous structure.

[0044] In step S3, the carbonization of the pre-oxidized filaments of the porous polymer fiber web is staged heating carbonizati...

Embodiment 1

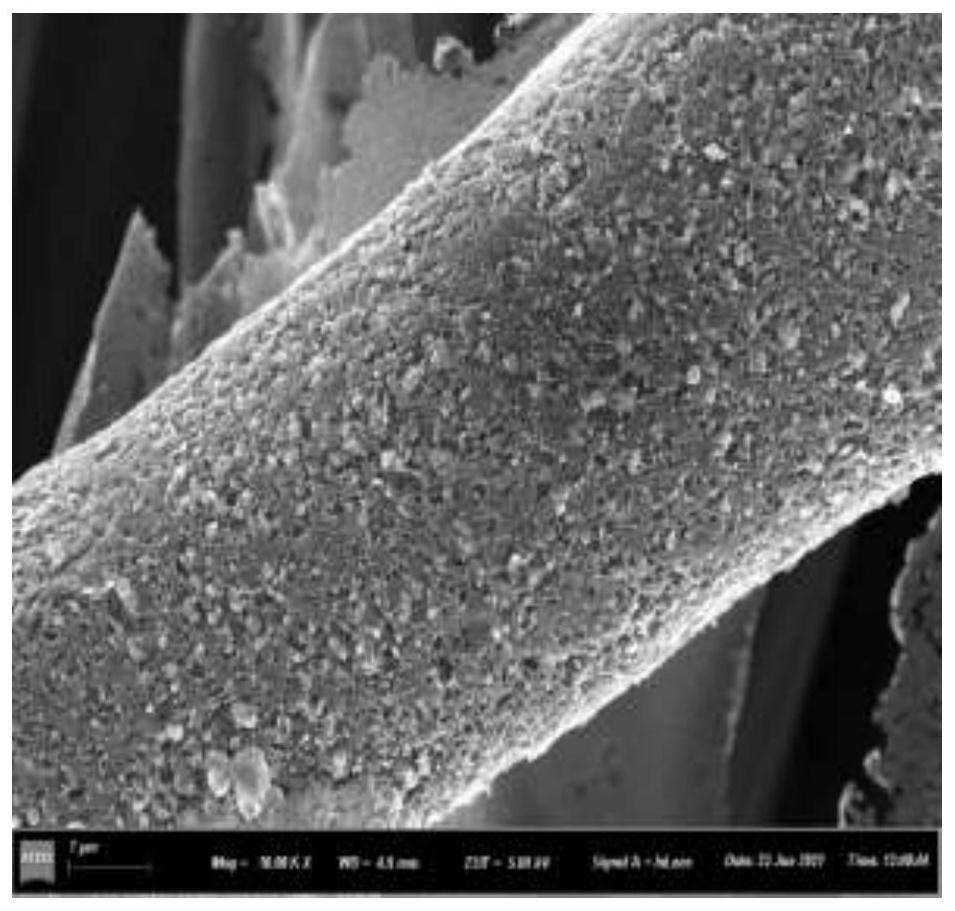

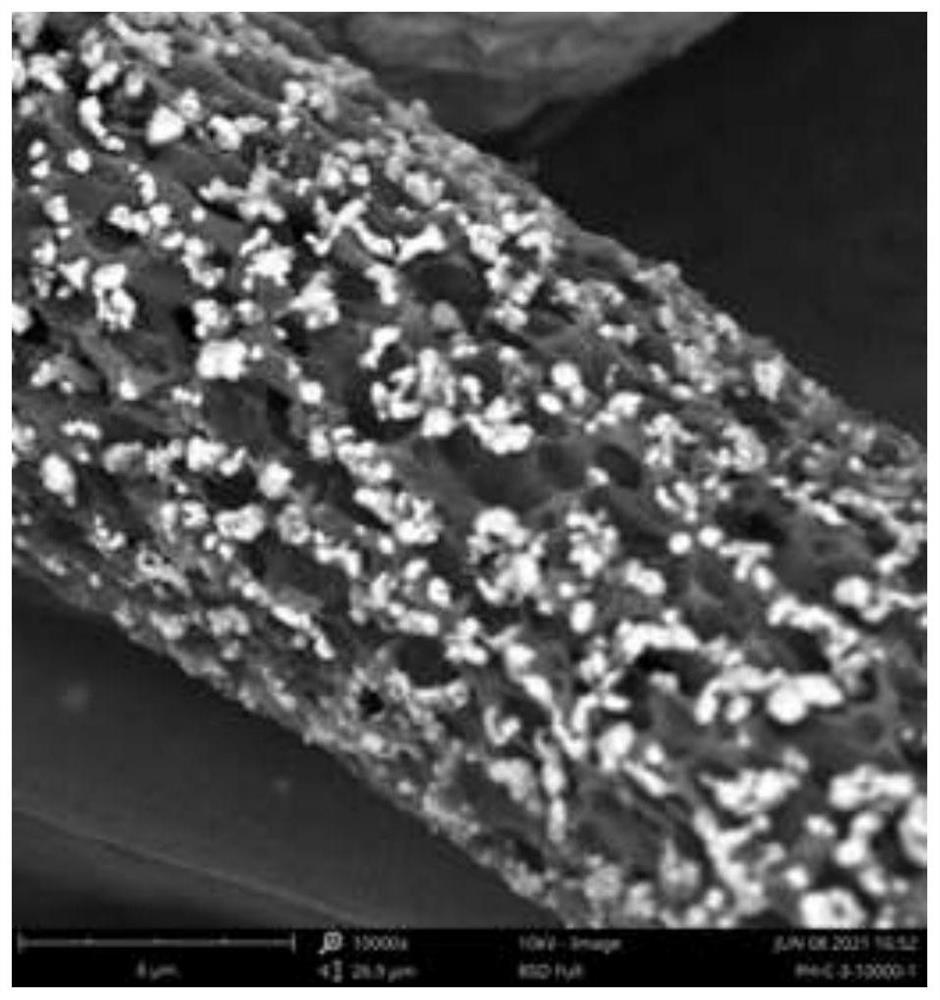

[0057] A method for preparing a porous carbon fiber-based catalyst through the desublimation of metal oxides in a carbonization process, comprising the steps of:

[0058] S1. Preparation of carbon fiber mesh: first dissolve polyacrylonitrile powder and polyethylene glycol in a mixed solution of N,N-dimethylformamide (DMF) and acetone, and stir to form a mass fraction of polyacrylonitrile of 17%. , polyethylene glycol mass fraction is 10% spinning solution (stirring speed is 200-800r / min, stirring time is 1-5h); Then the spinning solution is injected in the centrifugal spinning device and carries out centrifugal spinning (centrifugal spinning The rotation speed of the filaments is 5000r / min, the spinneret aperture is 0.2mm, the spinning temperature is 60°C, and the collection distance is 10cm) and collected to obtain a polyacrylonitrile fiber web.

[0059] S2. Pre-oxidation of polyacrylonitrile fiber web: put the hot-pressed polyacrylonitrile fiber web layer into a muffle furna...

Embodiment 2

[0062] A kind of method that metal oxide desublimates compositely to prepare porous carbon fiber-based catalyst in the carbonization process, compared with embodiment 1, the difference is that the content of polyethylene glycol and zinc oxide particle size and the highest carbonization temperature are as shown in Table 1 shown. Others are substantially the same as in Embodiment 1, and will not be repeated here.

[0063] The composite material of zinc oxide / porous carbon fiber mesh prepared above is used for the treatment of printing and dyeing wastewater. Take 20ml of organic wastewater containing methyl orange, put 0.04g of zinc oxide / porous carbon fiber mesh into it, and irradiate it with a high-pressure mercury lamp for 30 minutes. Test the removal rate of methyl orange in the dye.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com