Aluminum borate whisker reinforced and toughened nonmetal-based composite material and preparation method thereof

A technology of aluminum borate whiskers and non-metallic materials, which is applied in the field of reinforcing and toughening non-metallic matrix composite materials, can solve the problems of poor fracture toughness, limit the industrial application of alumina ceramic materials, etc. Density, the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The invention also discloses a method for preparing aluminum borate whisker-reinforced and toughened non-metal matrix composite materials, comprising the following steps:

[0041] a. Mix aluminum borate whiskers with non-metallic materials and ball mill them;

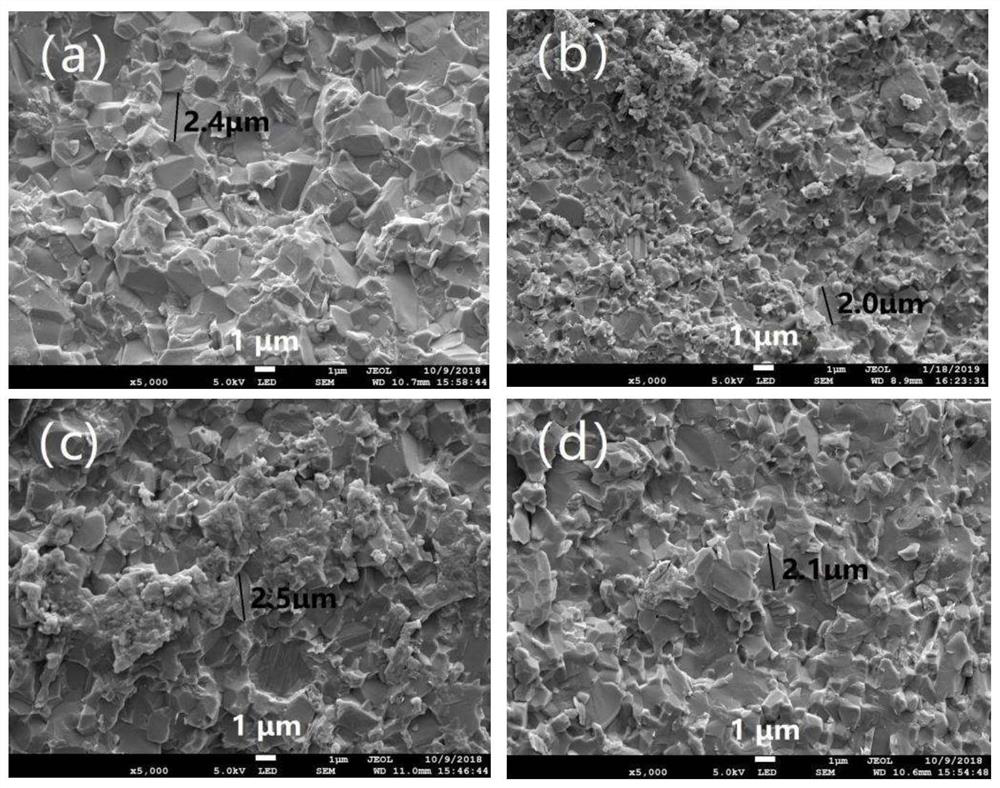

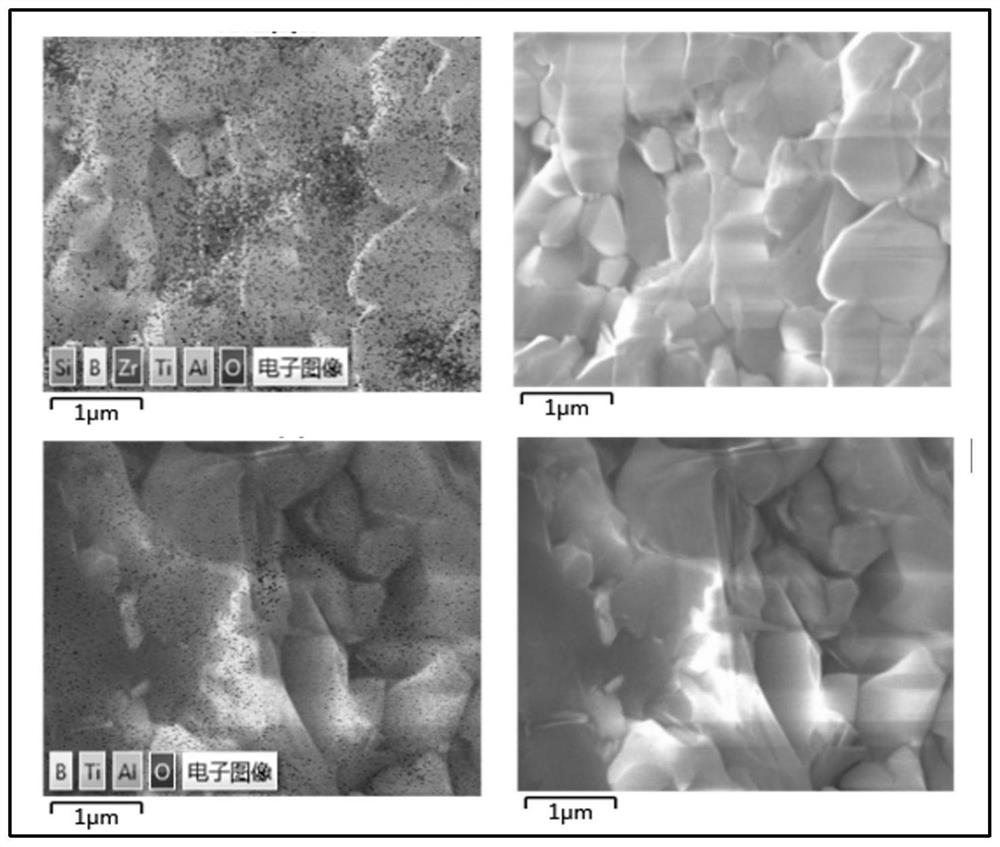

[0042] b. The mixture after ball milling is subjected to vacuum hot-pressing sintering treatment; the increase in fracture toughness of the composite material is mainly due to the toughening of the whiskers. Surface recrystallization forms needle-like whiskers, and bridges appear between some whiskers. Through the model of the increase in fracture toughness of composites caused by bridging whiskers, it can be seen that the fracture toughness of composites increases with the increase of whisker volume fraction. At the same time, crack deflection and bridging due to toughening whiskers will also improve the fracture toughness of the material. The wear performance of composite materials is mainly affected by the c...

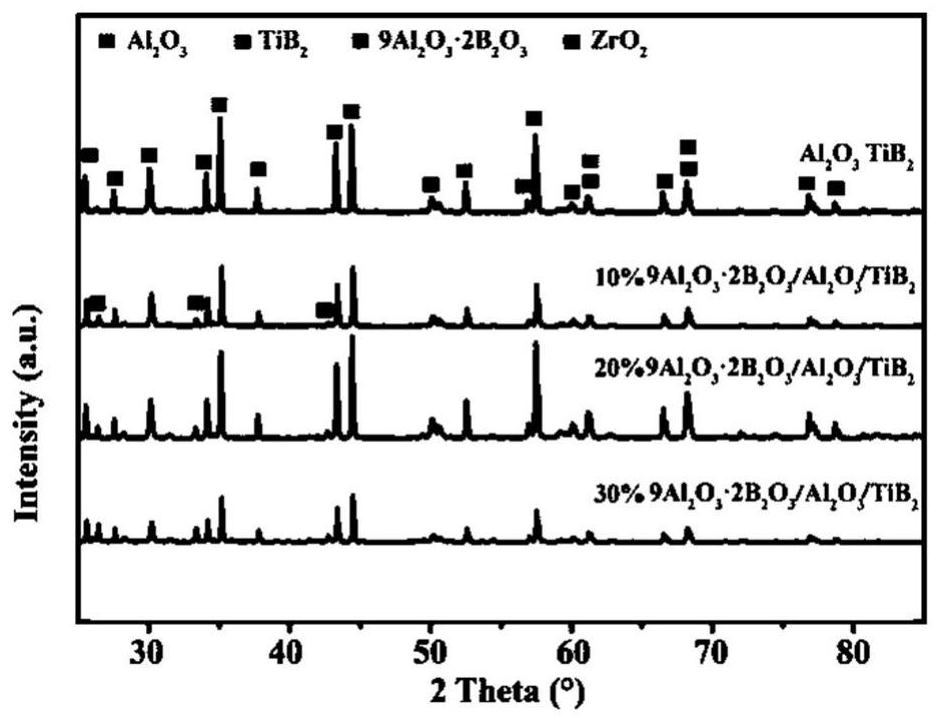

Embodiment 1

[0051] The aluminum borate whisker reinforced toughening alumina-based composite ceramics of this embodiment adopts 9Al 2 o 3 2B 2 o 3 Aluminum borate whiskers reinforced toughened alumina ceramic material (Al with a volume ratio of 4:1 2 o 3 / TiB 2 ); the length of the aluminum borate whisker is 5 μm, and the diameter is 0.4 μm; the addition of the aluminum borate whisker is 20% (composite material total amount), and its preparation method is:

[0052] a. Add aluminum borate whiskers, alumina ceramic materials and zirconia grinding balls into a ball milling pot and mill until the particle size of the powder is less than 1.0 μm;

[0053] b. The mixture after ball milling is subjected to vacuum hot pressing sintering treatment; the sintering temperature is 1500°C, the sintering pressure is 36MPa, and the holding time is 60min.

Embodiment 2

[0055] The aluminum borate whisker reinforced toughening alumina-based composite ceramics of this embodiment adopts 9Al 2 o 3 2B 2 o 3 Aluminum borate whisker reinforced toughened alumina ceramic material (volume percentage is 56% Al 2 o 3 , 14%TiB 2 ); the length of the aluminum borate whisker is 15 μm, and the diameter is 1.0 μm; the addition of the aluminum borate whisker is 30% (composite material total amount), and its preparation method is:

[0056] a. Add aluminum borate whiskers, alumina, titanium diboride powder and zirconia grinding balls into a ball milling pot and mill until the particle size of the powder is less than 1.0 μm;

[0057] b. Vacuum hot pressing sintering treatment is carried out on the mixture after ball milling; the sintering temperature is 1380° C., the sintering pressure is 5 MPa, and the holding time is 30 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com