Concrete admixture as well as preparation method and application thereof

A concrete admixture and unsaturated technology, which is applied in the field of concrete admixtures, can solve the problems of large fluctuations in particle gradation and other parameters, achieve excellent adaptability, strong adaptability, and reduce construction difficulty and workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

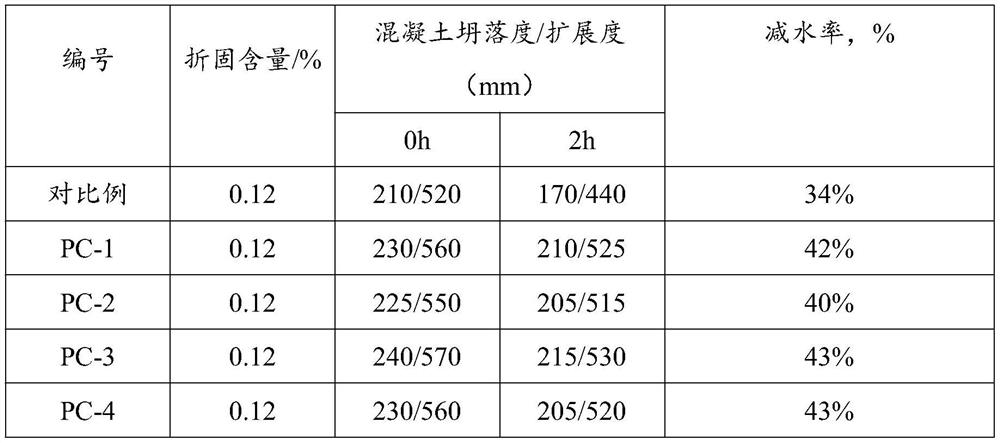

Examples

preparation example Construction

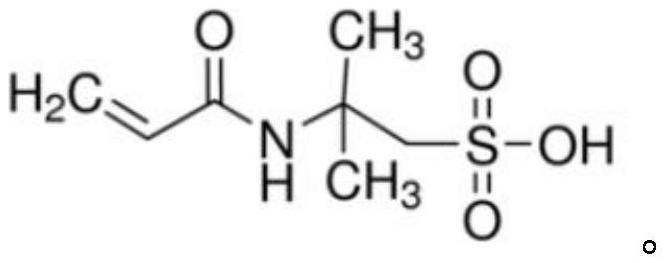

[0032] n=15~20, because it contains mercapto group, it can play the role of chain transfer, no additional chain transfer agent is added, the process is safe and simple, green and environmentally friendly, low energy consumption, low cost, suitable for industrial scale production; Oxypolyethylene glycol thioglycolate is prepared by the following method: methoxypolyethylene glycol (structural formula CH 3 O(CH 2 CH 2 O) n H, n=15~20) and mineral trioxide agglomerate (MTA) are mixed evenly, and concentrated sulfuric acid is added dropwise when heated to 35~45°C, and continuously stirred, until the temperature of the reaction solution rises to 115~130°C, add dropwise After completion, the dropping time is 3 hours. After the dropping, the temperature is lowered to 80-95°C and kept warm for 6 hours to obtain the branched chain functional monomer methoxypolyethylene glycol thioglycolate; wherein concentrated sulfuric acid accounts for methoxypolyethylene glycol 0.4wt%-0.8wt% of ...

Embodiment 1

[0038] The concrete admixture provided in this example is made of raw materials: methallyl polyoxyethylene ether, acrylic acid, and methoxy polyethylene glycol with a molar ratio of 1:0.015:0.2:0.003:0.15:0.1:0.002:0.01 Thioglycollate, 2-acrylamide-2-methylpropanesulfonic acid, polymerizable methacryloyloxypropyl phosphate, unsaturated mud inhibitor, hydrogen peroxide, L-ascorbic acid.

[0039] The method for preparing concrete admixture provided by the present embodiment comprises the following steps:

[0040] (1) Add methallyl polyoxyethylene ether and water to the container to prepare a bottom liquid with a concentration of 25wt%;

[0041] (2) Weigh acrylic acid, methoxypolyethylene glycol thioglycolate, 2-acrylamide-2-methylpropanesulfonic acid, polymerizable methacryloxypropyl phosphate, unsaturated Add mud inhibitor and hydrogen peroxide, mix well and add water to prepare a solution A with a concentration of 3.5wt%; mix the reducing agent with water to prepare a solutio...

Embodiment 2

[0044] The concrete admixture provided in this example is made of raw materials: methallyl polyoxyethylene ether, acrylic acid, and methoxy polyethylene glycol with a molar ratio of 1:0.02:0.025:0.4:0.18:0.15:0.03:0.015 Thioglycollate, 2-acrylamide-2-methylpropanesulfonic acid, polymerizable methacryloyloxypropyl phosphate, unsaturated mud inhibitor, hydrogen peroxide, L-ascorbic acid.

[0045] The method for preparing concrete admixture provided by the present embodiment comprises the following steps:

[0046] (1) Add methallyl polyoxyethylene ether and water to the container to prepare a bottom liquid with a concentration of 28wt%;

[0047] (2) Weigh acrylic acid, methoxypolyethylene glycol thioglycolate, 2-acrylamide-2-methylpropanesulfonic acid, polymerizable methacryloxypropyl phosphate, unsaturated Add mud inhibitor and hydrogen peroxide, mix well and add water to prepare a solution A with a concentration of 3.7wt%; mix the reducing agent with water to prepare a solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com