Antibacterial breathable film capable of being composted and degraded as well as a preparation method and application of antibacterial breathable film

A technology of compostable degradable and breathable membrane, which is applied in the field of antibacterial and compostable degradable breathable membrane and its preparation, which can solve the problems of difficulty in ensuring the quality consistency of the breathable membrane, slow heating without effect, and small skin air permeability, etc., to reduce The number of times of mold cleaning, the improvement of surface appearance, and the effect of ensuring shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

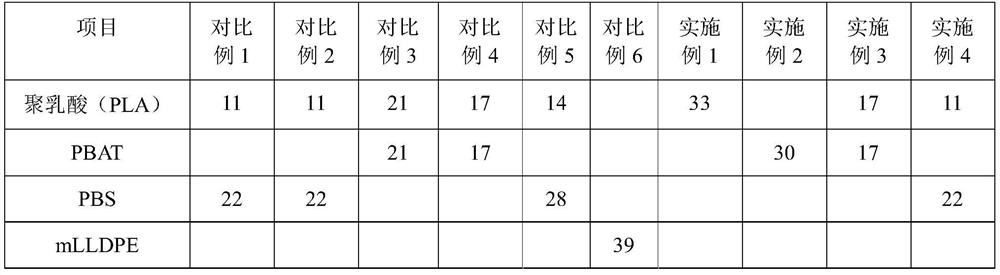

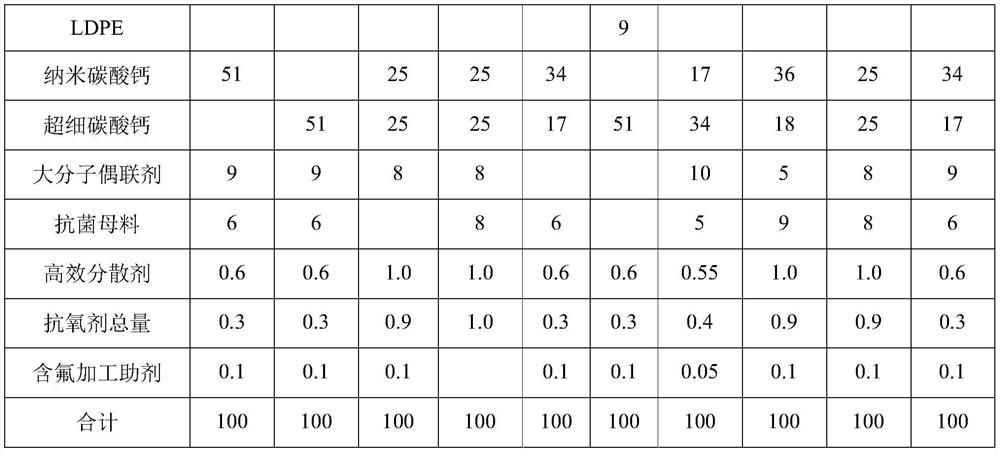

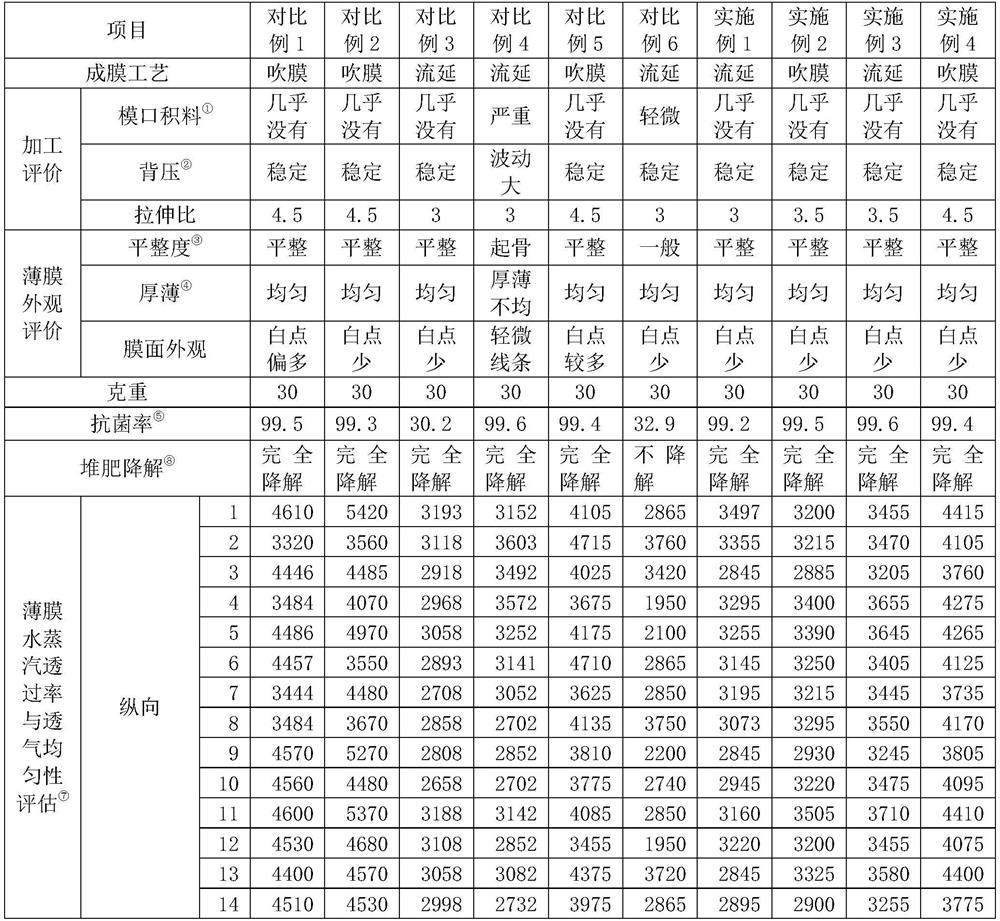

Method used

Image

Examples

Embodiment 1

[0057] Example 1 Preparation of antibacterial and degradable breathable film

[0058] (1) carry out surface coating treatment to nano calcium carbonate (commercially available, average particle size is 50 nanometers) in high-speed mixer with surface modifier to obtain coated calcium carbonate, and the consumption of surface modifier is the total amount of nano calcium carbonate 2.0% (mass percentage) of the amount, the surface modifiers are isopropyl dioleic acid acyloxy (dioctyl phosphoric acid acyloxy) titanate and isopropoxy two (octadecyloxy) aluminum ( The ratio of the two is a mass ratio of 1:1, wherein the isopropoxybis(octadecyloxy)aluminum is prepared according to Example 1 of the patent application document "CN85102942-New Type Aluminum System Coupling Agent"). The processing conditions were as follows: the rotational speed was 5000 r / min, the processing temperature was 100° C., and the processing time was 40 min.

[0059] (2) superfine calcium carbonate (commercial...

Embodiment 2

[0065] (1) carry out surface coating treatment to nano calcium carbonate (commercially available, average particle size is 150 nanometers) in a high-speed mixer with a surface modifier to obtain coated calcium carbonate, and the consumption of the surface modifier is the total amount of calcium carbonate 0.5% (mass percent), the surface modifier is bis(dioctyloxypyrophosphate) ethylene titanate and isopropoxybis(dodecyltoluenesulfonyloxy)aluminum (isopropyl) The oxybis(dodecyltoluenesulfonyloxy)aluminum was prepared according to Example 5 of the patent application document "CN85102942-New Type Aluminum System Coupling Agent"), and the ratio of the two was 2:1. The processing conditions were as follows: the rotational speed was 3000 r / min, the processing temperature was 120° C., and the processing time was 20 min.

[0066] (2) superfine calcium carbonate (commercially available, with an average particle size of 1.0 μm) is subjected to surface coating treatment in a high-speed m...

Embodiment 3

[0072] (1) carry out surface coating treatment to nano calcium carbonate (commercially available, average particle size is 100 nanometers) in a high-speed mixer with a surface modifier to obtain coated calcium carbonate, and the consumption of the surface modifier is the total amount of calcium carbonate 1.5% (mass percent), the surface modifier is bis(dioctyloxypyrophosphate) ethylene titanate and isopropoxybis(octadecyloxy)aluminum, and the ratio of the two is 2: 1. The processing conditions were as follows: the rotational speed was 4000 r / min, the processing temperature was 100 °C, and the processing time was 30 min.

[0073] (2) Surface coating treatment of ultrafine calcium carbonate (particle size of 5.0 μm) with surface modifier lauric acid and myristic acid (mass ratio of 1:1) in a high-speed mixer to obtain coated carbonic acid Calcium, the amount of surface modifier is 1.0% (mass percent) of the total calcium carbonate. The processing conditions were as follows: th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com