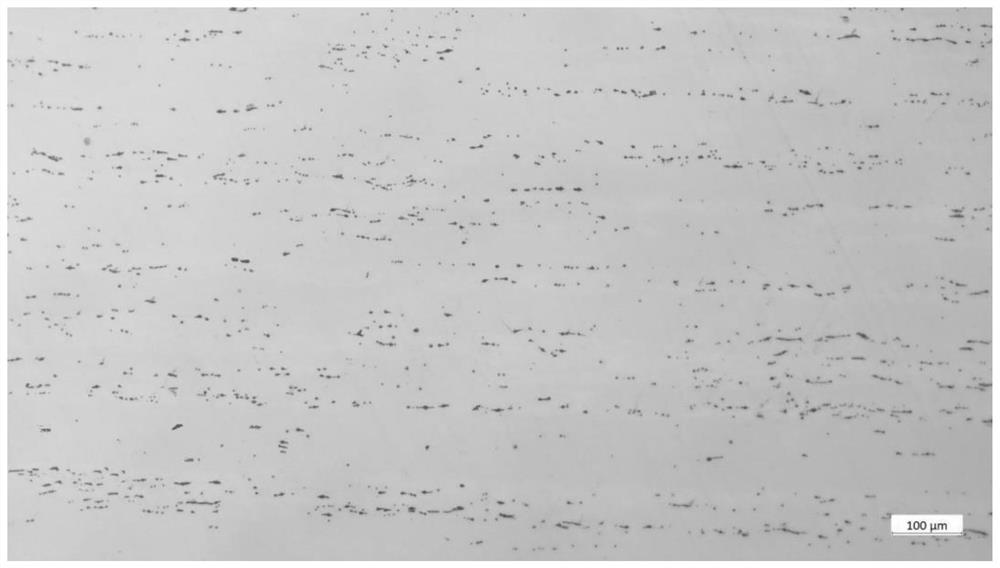

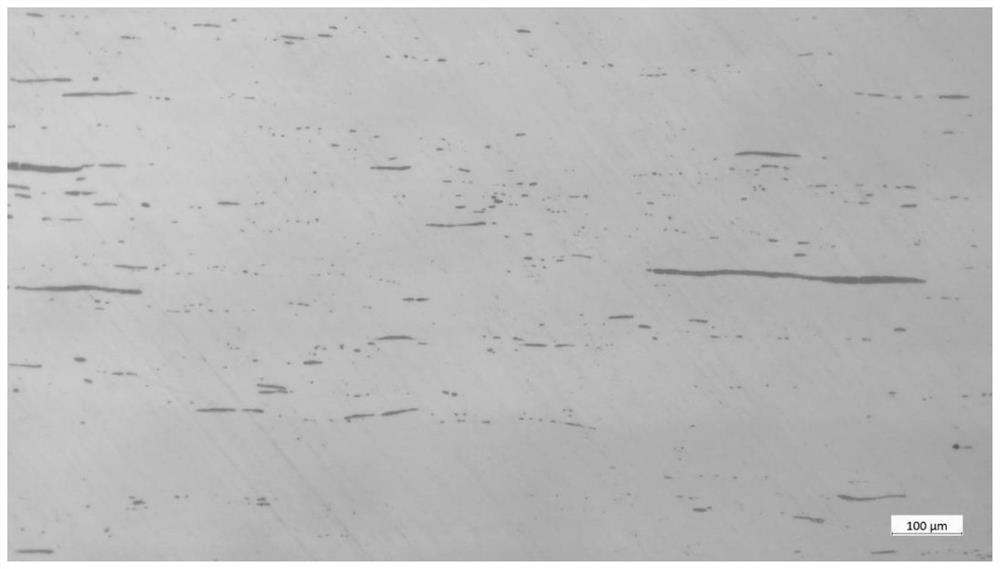

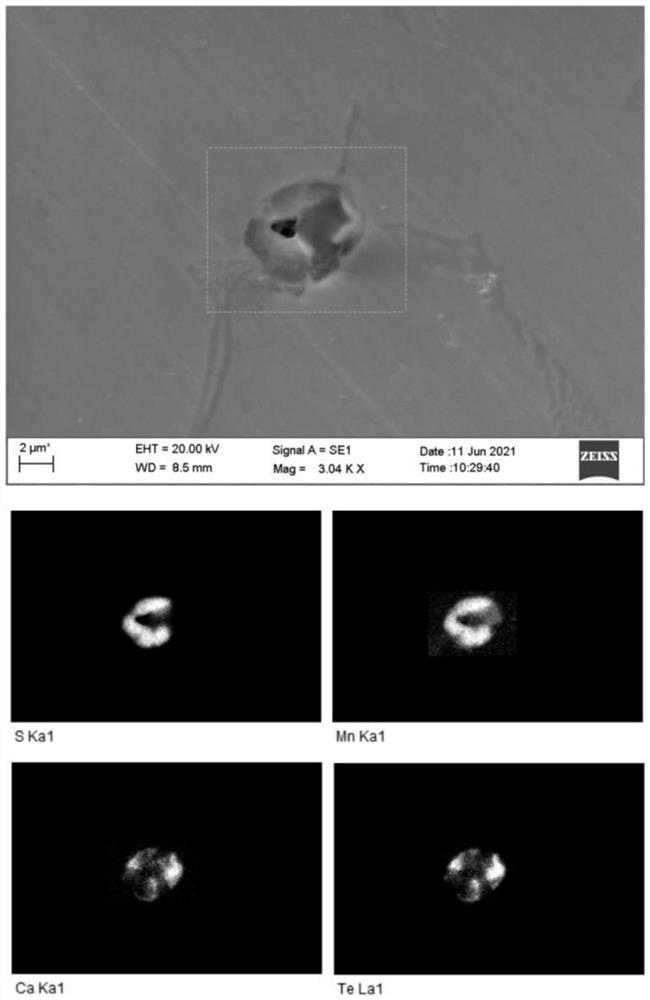

Ultra-free-cutting stainless steel subjected to calcium-tellurium-rare earth composite treatment and preparation method thereof

A technology of rare earth compounding and stainless steel, which is applied in the field of steel manufacturing, can solve the problems of reducing the mechanical properties of sulfides affecting machinability, affecting the yield and mechanical properties of stainless steel, and the impact of stainless steel yield and mechanical properties, etc., to achieve optimal smelting process, good mechanical properties, and the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: preparation method disclosed in calcium-treated ultrapure tellurium rare earth complex cutting stainless steel of the present invention, comprises the steps of,

[0035] EAF S1, the pre-pad on the bottom 30t 1000kg lime electric arc furnace, and then low P, low five harmful elements (Pb, Sn, As, Sb, Bi) of stainless steel scrap into electric arc furnace melting, melt blowing process oxygen flux, blown oxygen to 395m 3 , After the end of 310kg molten ferrosilicon by reduction into an arc furnace, after the end of the reduction Pa 3 / 4 steel slag, tapping the control P≤0.030%, to give crude water;

[0036] S2AOD refining, sequentially 1000-2000kg lime, iron-chromium, nickel-chromium alloy cold material, Sl obtained crude water into the AOD furnace, gas blowing, and then controls the AOD furnace and heated oxygen blowing decarburization refining, until the crude 0.001 to 0.015% C content of the water reaches, again charged with 800kg AOD furnace reduction of ferrosil...

Embodiment 2

[0042] Example 2: Preparation of Ultra-cutting stainless steel discloses a rare earth complex of the present invention, tellurium calcium treated as in Example 1 except that the parameter conditions of each step are shown in Table 2, to obtain stainless steel.

[0043] Solution per 100 parts of the raw material per 100 parts of stainless steel and pickling of parts by weight of the components shown in Table 1.

Embodiment 3

[0044] Example 3: Preparation of Ultra-cutting stainless steel discloses a calcium tellurium rare earth complex process of the present invention, as in Example 1 except that the parameter conditions of each step are shown in Table 2, to obtain stainless steel.

[0045] Solution per 100 parts of the raw material per 100 parts of stainless steel and pickling of parts by weight of the components shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com