Super-leveling powder coating and preparation method thereof

A powder coating and leveling technology, which is applied in powder coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of general leveling and lower coating film quality, reduce production costs, improve mechanical properties, and improve The effect of surface hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of described modified polyester resin comprises the following steps:

[0044] (1) Add ethylene glycol, diethylene glycol, pentylene glycol, and monobutyltin oxide to the reaction kettle in sequence, then adjust the temperature to 118°C, and keep stirring for 30 minutes;

[0045] (2) Add terephthalic acid and maleic acid to the reaction kettle in step (1) and add them to the reaction kettle in turn, then adjust the temperature value to 235° C., and keep stirring for 40 minutes;

[0046] (3) Add antioxidant TPPi to the reactor in step (3), stir for 10min;

[0047] (4) Sampling the reaction kettle in step (4) when the acid value reaches 16mgKOH / g, lower the temperature to 180°C, then add polybasic acid, continue heating to 235°C, keep warm for 5 hours, and carry out after the resin is clarified Sampling Jiangce acid value reaches 60mgKOH / g, carry out vacuum polycondensation, the acid value reaches 52mgKOH, and then discharge at 200 ° C to obtain.

...

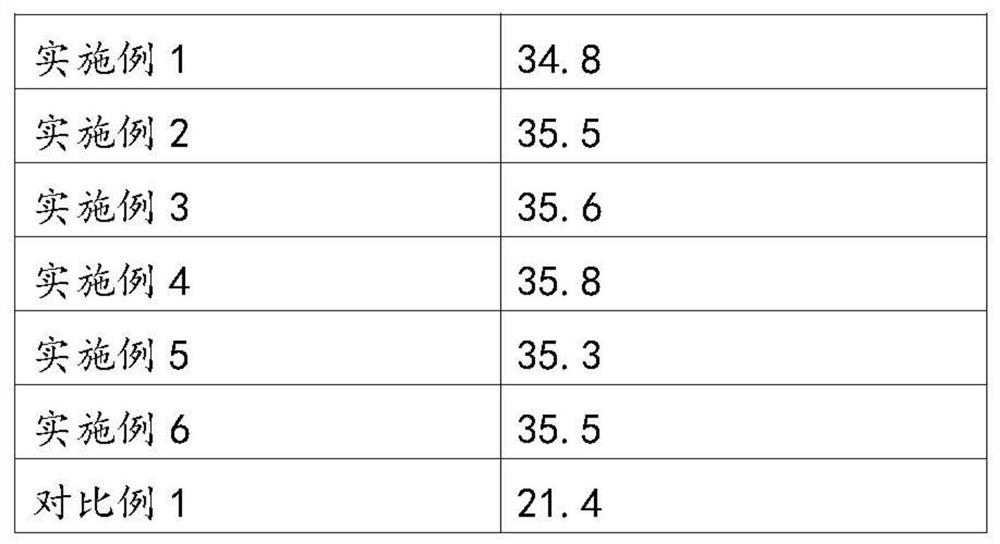

Embodiment 1

[0070] A super-leveling powder coating, made of the following components in parts by weight: modified polyester resin 120, titanium dioxide 10, acrylic resin 18, nano-silica 12, epoxy resin 11, composite leveling agent 3, Curing agent 6, ceramic micropowder 1, polytetrafluoroethylene micropowder wax 6, auxiliary agent 12. The 150°C melt viscosity of the epoxy resin is 4500 cps. The preparation method of described modified polyester resin comprises the following steps:

[0071] (1) Add ethylene glycol, diethylene glycol, pentylene glycol, and monobutyltin oxide to the reaction kettle in sequence, then adjust the temperature to 118°C, and keep stirring for 30 minutes;

[0072] (2) Add terephthalic acid and maleic acid to the reaction kettle in step (1) and add them to the reaction kettle in turn, then adjust the temperature value to 235° C., and keep stirring for 40 minutes;

[0073] (3) Add antioxidant TPPi to the reactor in step (3), stir for 10min;

[0074] (4) Sampling in...

Embodiment 2

[0081] A super-leveling powder coating, made of the following components in parts by weight: modified polyester resin 120, titanium dioxide 10, acrylic resin 18, nano-silica 12, epoxy resin 11, composite leveling agent 3.2, Curing agent 6, ceramic micropowder 1, polytetrafluoroethylene micropowder wax 6, auxiliary agent 120. The 150°C melt viscosity of the epoxy resin is 4500 cps. The preparation method of described modified polyester resin comprises the following steps:

[0082] (1) Add ethylene glycol, diethylene glycol, pentylene glycol, and monobutyltin oxide to the reaction kettle in sequence, then adjust the temperature to 118°C, and keep stirring for 30 minutes;

[0083] (2) Add terephthalic acid and maleic acid to the reaction kettle in step (1) and add them to the reaction kettle in turn, then adjust the temperature value to 235° C., and keep stirring for 40 minutes;

[0084] (3) Add antioxidant TPPi to the reactor in step (3), stir for 10min;

[0085] (4) Sampling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt viscosity | aaaaa | aaaaa |

| Melt viscosity | aaaaa | aaaaa |

| Melt viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com