Non-inductive multifunctional electrospinning micro-pyramid array film and preparation method thereof

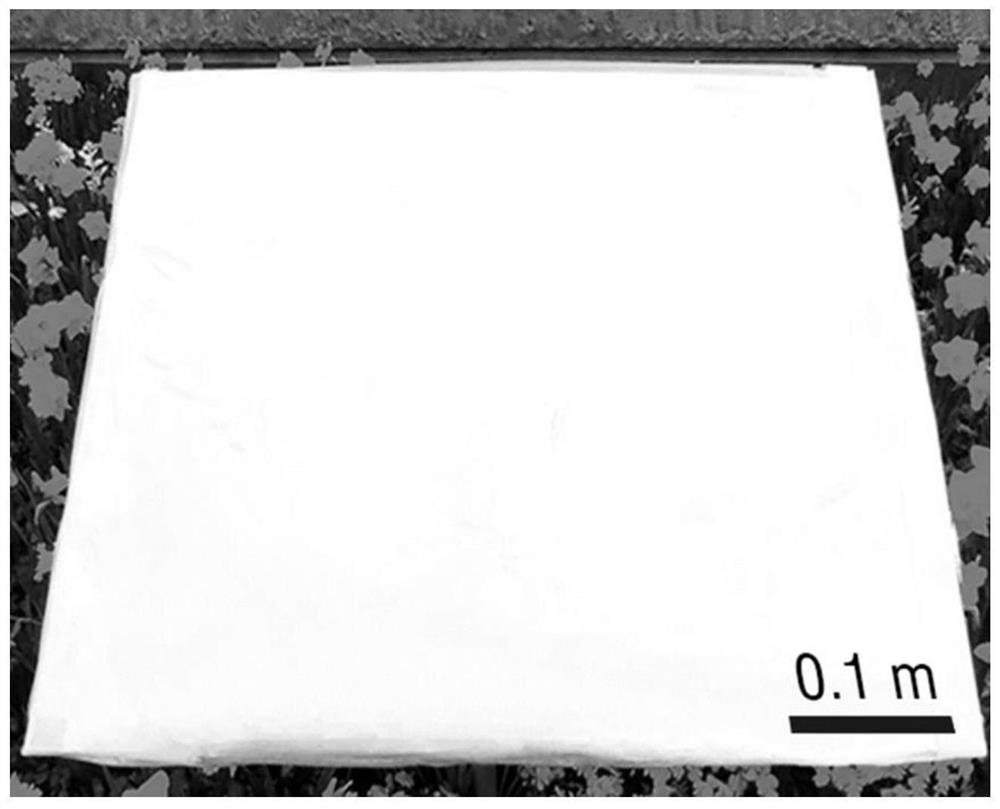

A pyramid, array membrane technology, applied in electrospinning, textile and papermaking, filament/thread forming, etc., can solve problems such as multidisciplinary performance and versatility of unfavorable related membrane devices, and achieve excellent performance and versatility , ultra-light weight, high efficiency and large-scale effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

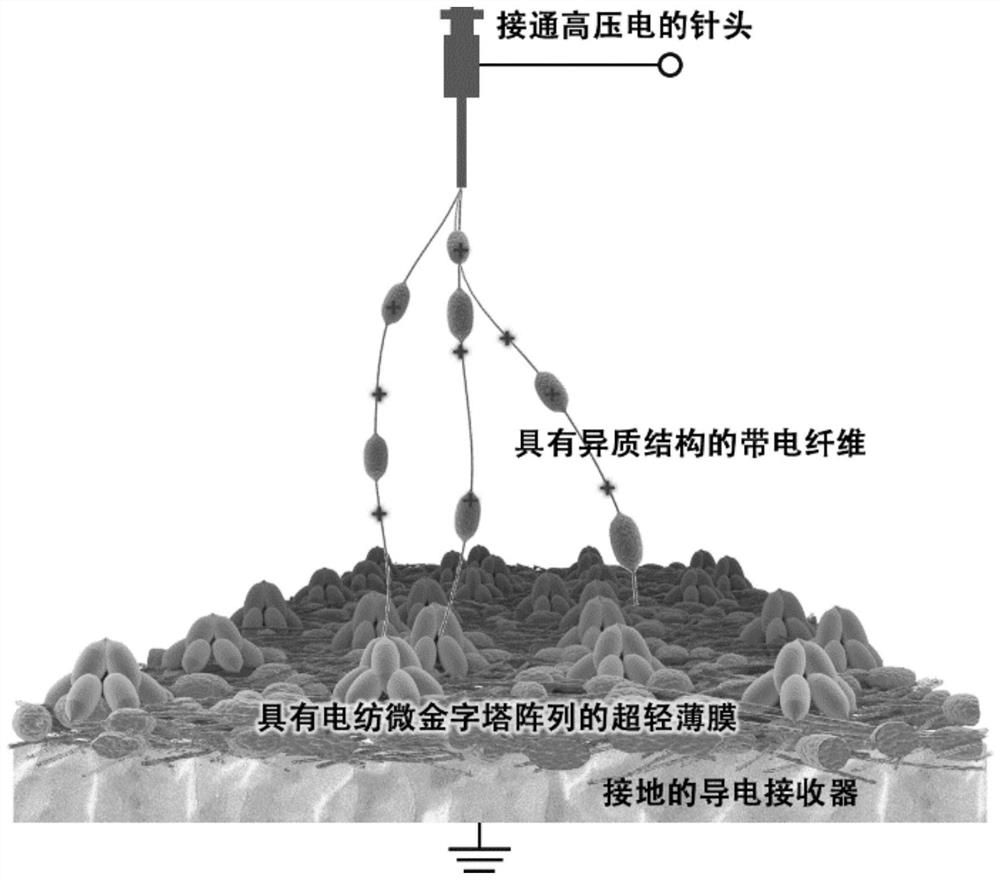

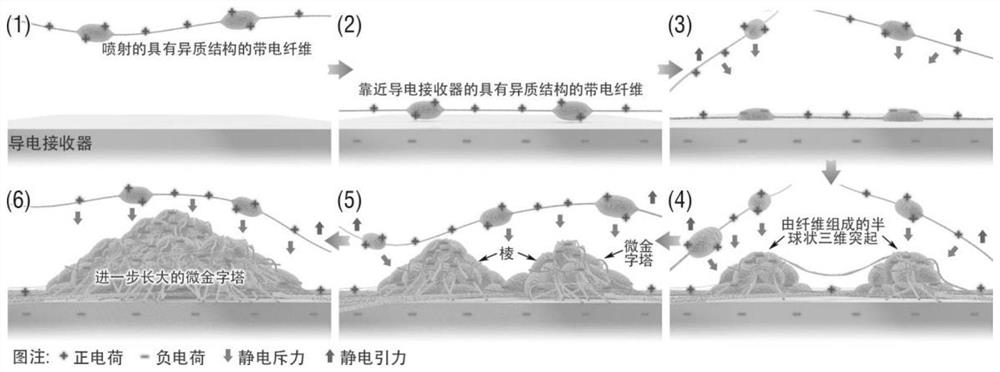

[0039] A method for preparing a non-inductive multifunctional electrospun micro-pyramid array film, comprising the steps of:

[0040] 1) adding the polymer into a high boiling point solvent, heating and stirring at a temperature lower than the boiling point of the solvent to fully dissolve the polymer, and then standing at 25°C to remove the bubbles generated during the stirring process to obtain a polymer precursor solution;

[0041] The polymer is any one of polyvinylidene fluoride, thermoplastic polyurethane elastomer rubber, polyvinyl alcohol, polyamide 66; the high boiling point solvent is suitable for dissolving polyvinylidene fluoride and thermoplastic polyurethane elastomer rubber The volume ratio of dimethyl sulfoxide and acetone mixed solution of 1:1 to 3:1, the water suitable for dissolving polyvinyl alcohol, and the corresponding solvent suitable for dissolving polyamide 66 in formic acid; the temperature of the heating and stirring 50°C to 55°C; the standing time ...

Embodiment 1

[0048] 1) Add polyvinylidene fluoride into a mixture of dimethyl sulfoxide and acetone with a volume ratio of 2:1, stir at 50°C to fully dissolve the polyvinylidene fluoride, and then let stand at 25°C for 15 minutes. Remove the bubbles generated during the stirring process to obtain a polyvinylidene fluoride solution with a mass concentration of 8.59%;

[0049] 2) Add the polyvinylidene fluoride solution obtained in step 1) into a No. 22 conductive needle, install a grounded conductive receiver at 8 cm in front of the needle, connect the 12.5 kV DC high voltage to the conductive needle, and set the temperature at 40% humidity And under the environment of 25 ℃, the polyvinylidene fluoride solution is formed under the action of a high-voltage electric field to form a fiber whose specific volume surface area is sprayed to the conductive receiver and which changes periodically along the length of the fiber;

[0050] 3) Use a mechanical pump to control the flow rate of the polyvin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com