Rail side semi-flexible transition structure of urban tramcar and construction method thereof

A technology for trams and transitional structures, applied in the direction of track superstructure, tracks, roads, etc., can solve problems such as cracking, insufficient density of asphalt concrete, damage, etc., and achieve no increase in construction period, excellent fatigue resistance and chemical stability The effect of sex and color difference is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

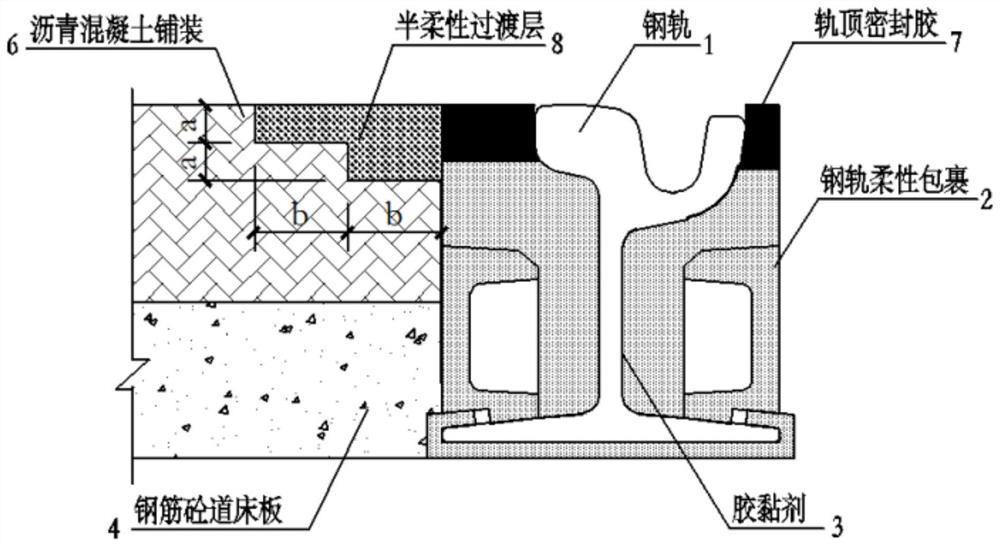

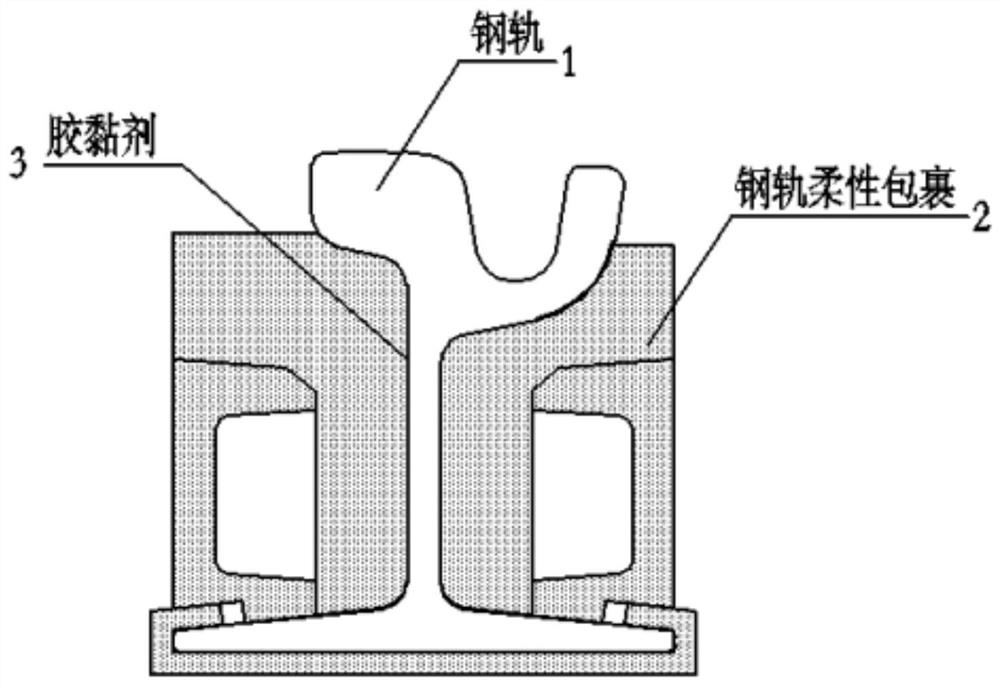

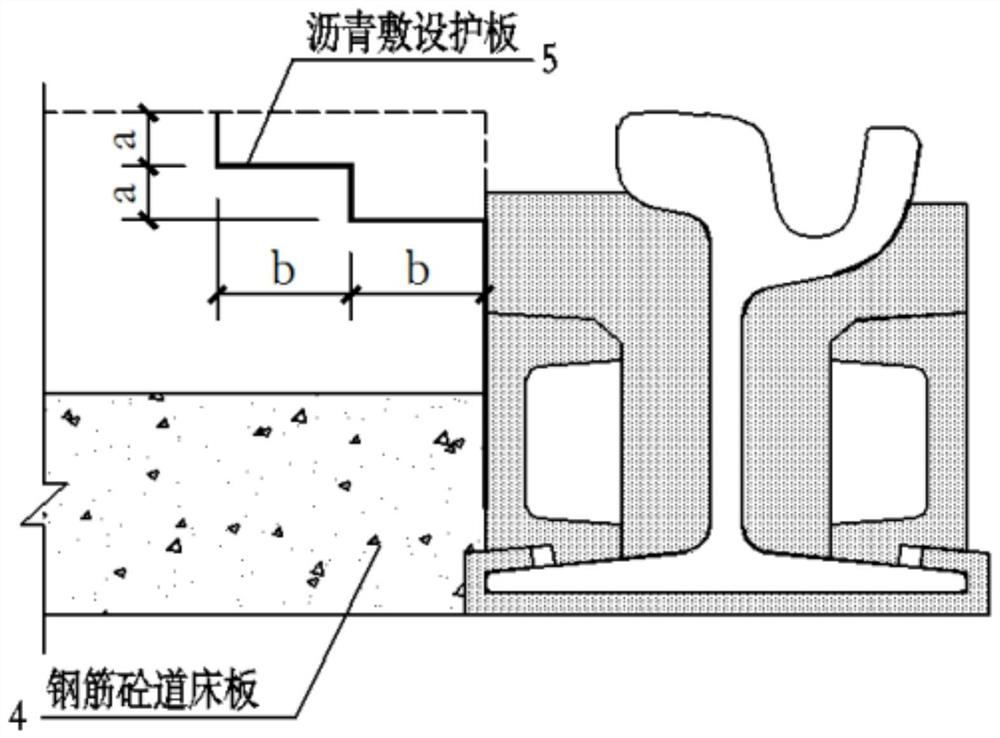

[0043] Such as figure 1 As shown, the rail side semi-flexible transition structure of an urban tram includes a rail 1; the middle and lower parts of the rail 1 are provided with a flexible rail wrap 2 through an adhesive 3; both sides of the rail 1 are close to the upper position, and the flexible wrap 2 of the rail is A rail top sealant 7 is provided above; the outer side of the rail 1 is provided with reinforced concrete track bed slabs 4 and asphalt concrete pavement 6 sequentially from bottom to top.

[0044] Among them, the asphalt concrete pavement 6 and the rail top sealant 7 are provided with a semi-flexible transition layer 8;

[0045] The semi-flexible transition layer 8 is a polymer composite material, and after hardening, its stiffness is between that of the asphalt concrete pavement 6 and the rail top sealant 7;

[0046] A groove for filling the semi-flexible transition layer 8 is provided on the upper surface of the asphalt concrete pavement 6 near the rail top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com