High-integration high-reliability IGBT power module and manufacturing method thereof

A technology of power modules and manufacturing methods, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of poor high-voltage resistance performance of IGBT modules, complex heat dissipation measures, and low assembly density, and achieve quality consistency Good, meet the technical development and market demand, the effect of high assembly density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

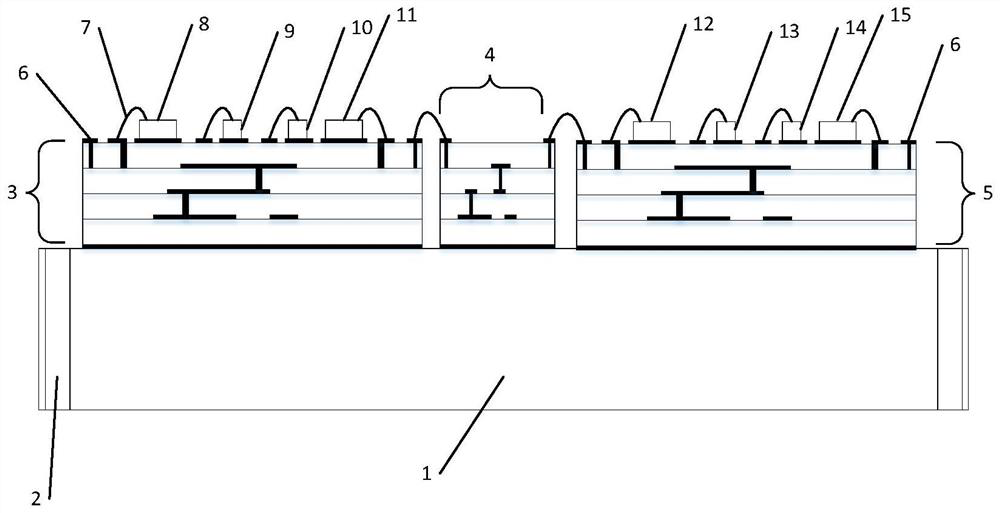

[0031] Such as figure 2 As shown, the specific implementation is as follows:

[0032] The bonding wire is a silicon-alumina wire with a diameter of 500 microns.

[0033] The number of bonding wires is 1 grid, and 4-10 collectors and emitters.

[0034] The metal bottom plate is rectangular, the four corners of the metal bottom plate are provided with metal bottom plate fixing holes, and the metal bottom plate and the module shell are fixed together by rivets.

[0035] The module shell is made of PBT engineering plastic, which has high temperature resistance and low mass.

[0036] The wire mesh is a wire mesh.

[0037] The substrate welding or chip welding is reflow welding or alloy welding.

[0038] The specific production process is:

[0039] (1) screen printing, the solder paste is printed on the surface of the multilayer ceramic substrate according to the set pattern, and the preliminary preparation is done for the patch, and the screen is a barbed wire;

[0040] (2) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com