Polyimide/polyetherimide composite membrane and preparation method thereof

A technology of polyetherimide and polyetherimide layer, which is applied in the field of polyimide/polyetherimide composite membrane and its preparation, and can solve problems such as high cost, large pore size of fiber membrane, and complicated process , to achieve enhanced mechanical properties, good flame retardancy, and stable pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

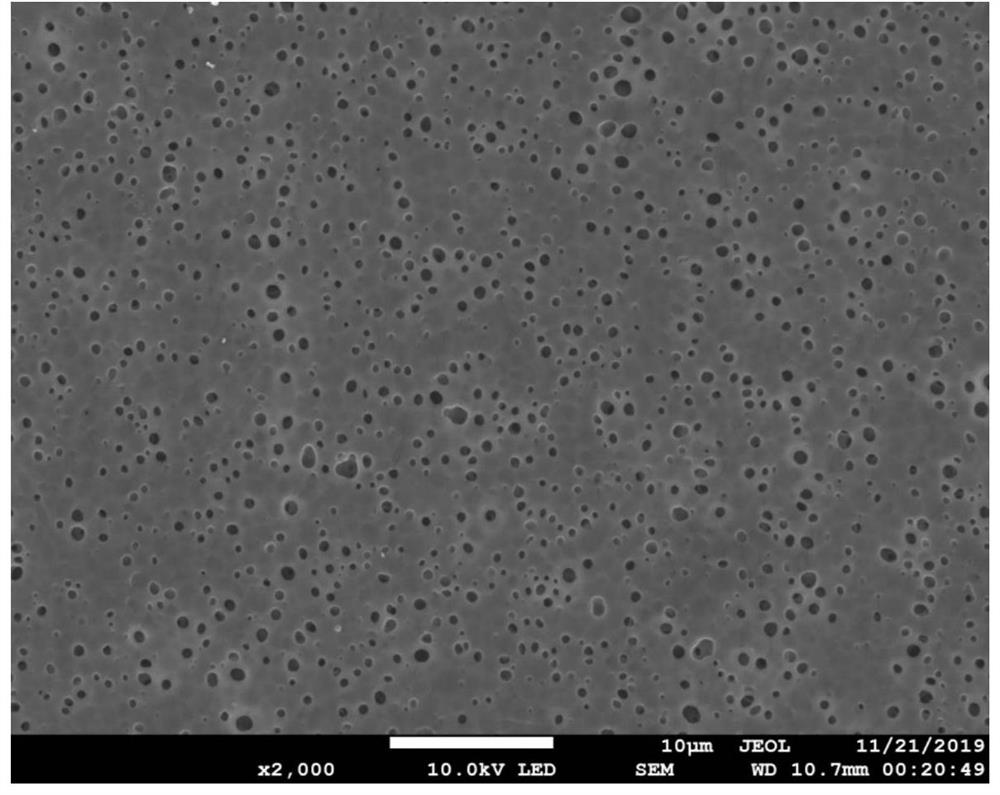

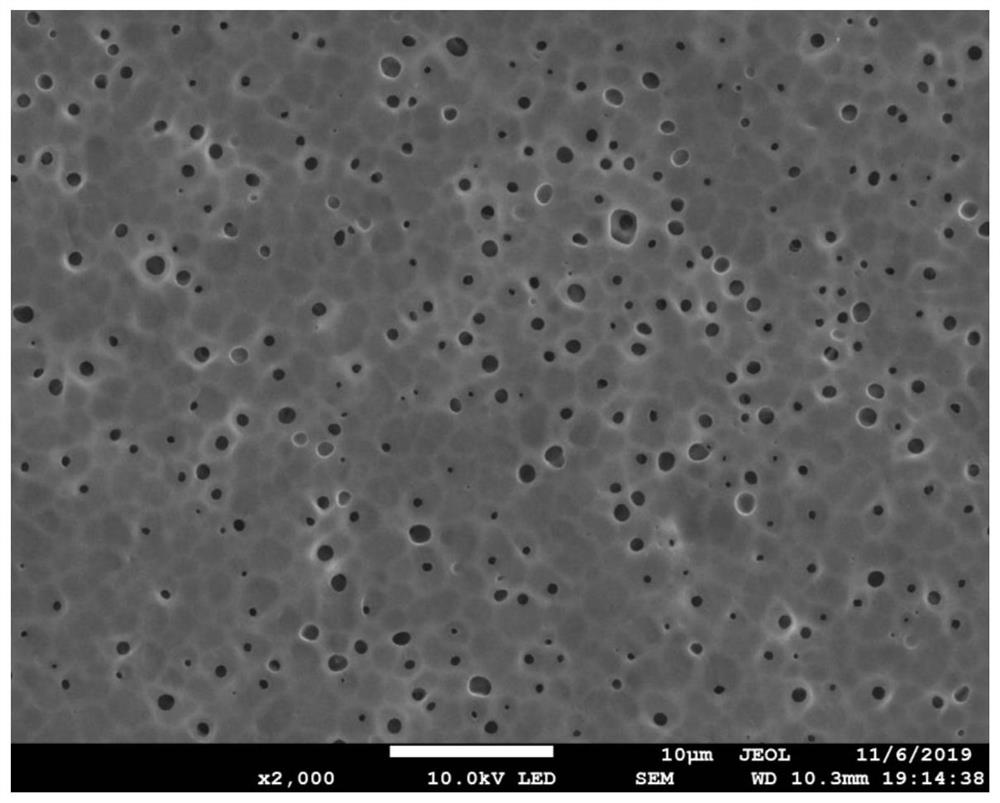

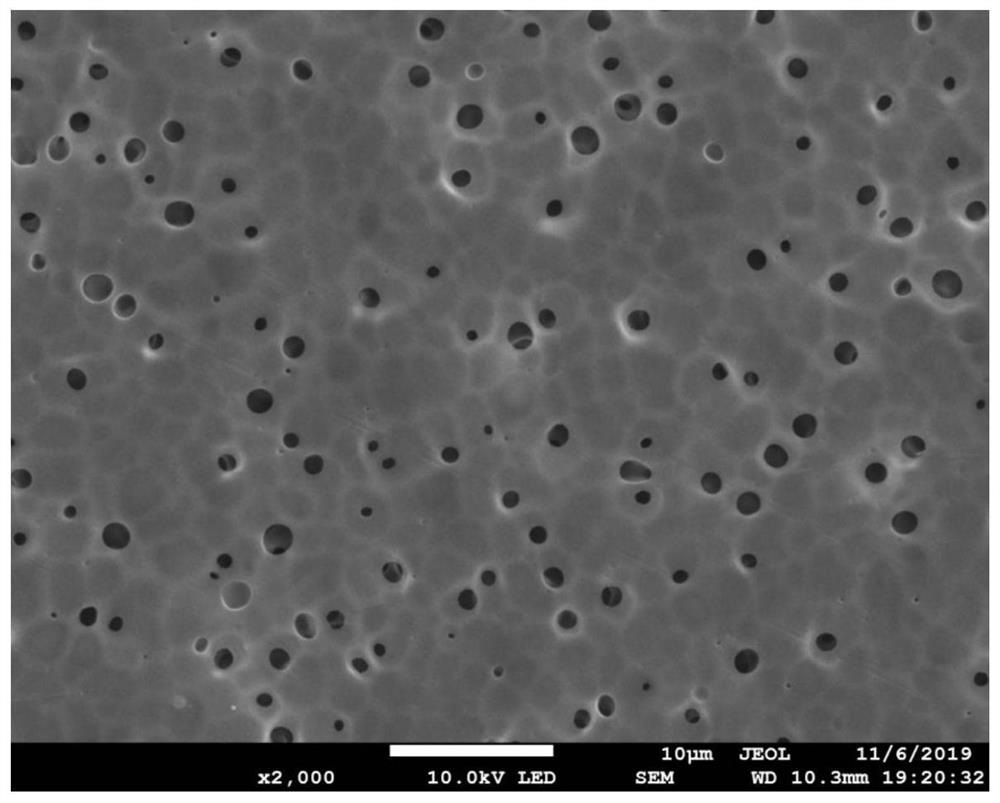

Image

Examples

Embodiment 1

[0035] First, a PMDA / ODA system polyamic acid solution with a solid content of 12% was prepared, a polyamic acid nanofiber membrane was prepared by electrospinning, and a polyimide nanofiber membrane was obtained by thermal imidization.

[0036](1) Weigh 2.03g of pyromellitic dianhydride (PMDA) and 1.84g of 4,4'-diaminodiphenyl ether (ODA) at a molar ratio of 1:1, and dissolve all ODA in 30ml of N,N- After being completely dissolved in dimethylformamide (DMF) solvent, PMDA was added in batches to prepare a polyamic acid solution with a solid content of 12%. The polyamic acid solution is prepared by electrospinning technology to prepare polyamic acid nanofiber membrane. The specific parameters of the electrospinning machine are: spinning voltage: 20kV; spinning temperature: 25°C; spinning humidity: 40%; syringe needle diameter: 12 No.; receiving roller speed: 500r / min; receiving distance: 20cm. The prepared PAA nanofiber membrane was subjected to thermal imidization treatment,...

Embodiment 2

[0041] First, a PMDA / ODA system polyamic acid solution with a solid content of 12% was prepared, a polyamic acid nanofiber membrane was prepared by electrospinning, and a polyimide nanofiber membrane was obtained by thermal imidization.

[0042] (1) Weigh 2.03g of pyromellitic dianhydride (PMDA) and 1.84g of 4,4'-diaminodiphenyl ether (ODA) at a molar ratio of 1:1, and dissolve all ODA in 30ml of N,N- After being completely dissolved in dimethylformamide (DMF) solvent, PMDA was added in batches to prepare a polyamic acid solution with a solid content of 12%. The polyamic acid solution is prepared by electrospinning technology to prepare polyamic acid nanofiber membrane. The specific parameters of the electrospinning machine are: spinning voltage: 20kV; spinning temperature: 25°C; spinning humidity: 40%; syringe needle diameter: 12 No.; receiving roller speed: 500r / min; receiving distance: 20cm. The prepared PAA nanofiber membrane was subjected to thermal imidization treatment...

Embodiment 3

[0047] First, a PMDA / ODA system polyamic acid solution with a solid content of 12% was prepared, a polyamic acid nanofiber membrane was prepared by electrospinning, and a polyimide nanofiber membrane was obtained by thermal imidization.

[0048] (1) Weigh 2.03g of pyromellitic dianhydride (PMDA) and 1.84g of 4,4'-diaminodiphenyl ether (ODA) at a molar ratio of 1:1, and dissolve all ODA in 30ml of N,N- After being completely dissolved in dimethylformamide (DMF) solvent, PMDA was added in batches to prepare a polyamic acid solution with a solid content of 12%. The polyamic acid solution is prepared by electrospinning technology to prepare polyamic acid nanofiber membrane. The specific parameters of the electrospinning machine are: spinning voltage: 20kV; spinning temperature: 25°C; spinning humidity: 40%; syringe needle diameter: 12 No.; receiving roller speed: 500r / min; receiving distance: 20cm. The prepared PAA nanofiber membrane was subjected to thermal imidization treatment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com