Method for preparing polyamide membrane through gas-phase polymerization, polyamide membrane and application

A technology of gas-phase polymerization and polyamide membrane, which is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as environmental hazards and increase the production cost of polyamide membranes, and avoid the use of organic solvents, excellent Effects of separation performance and wide versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

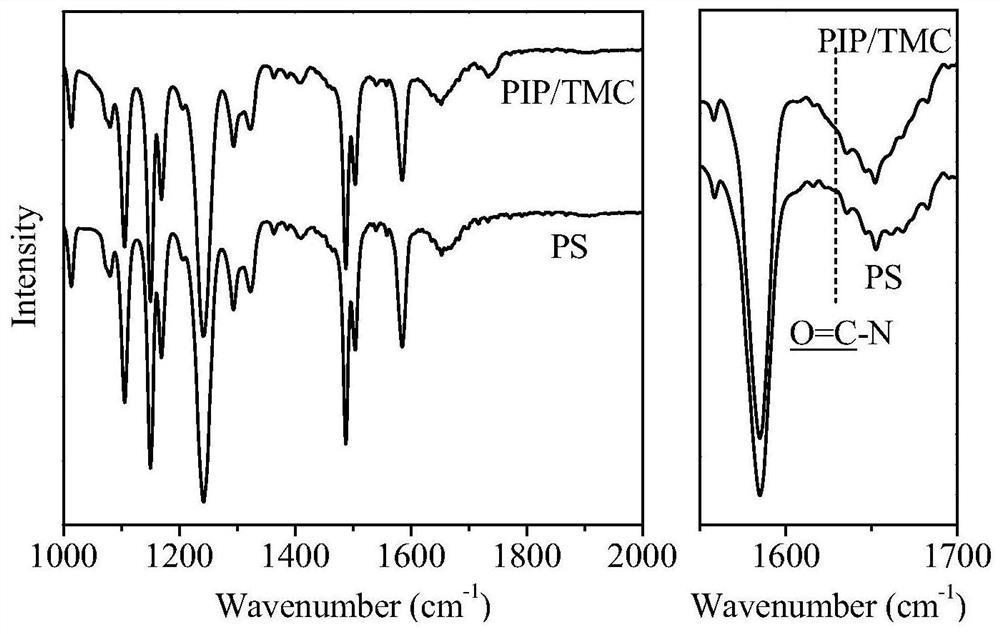

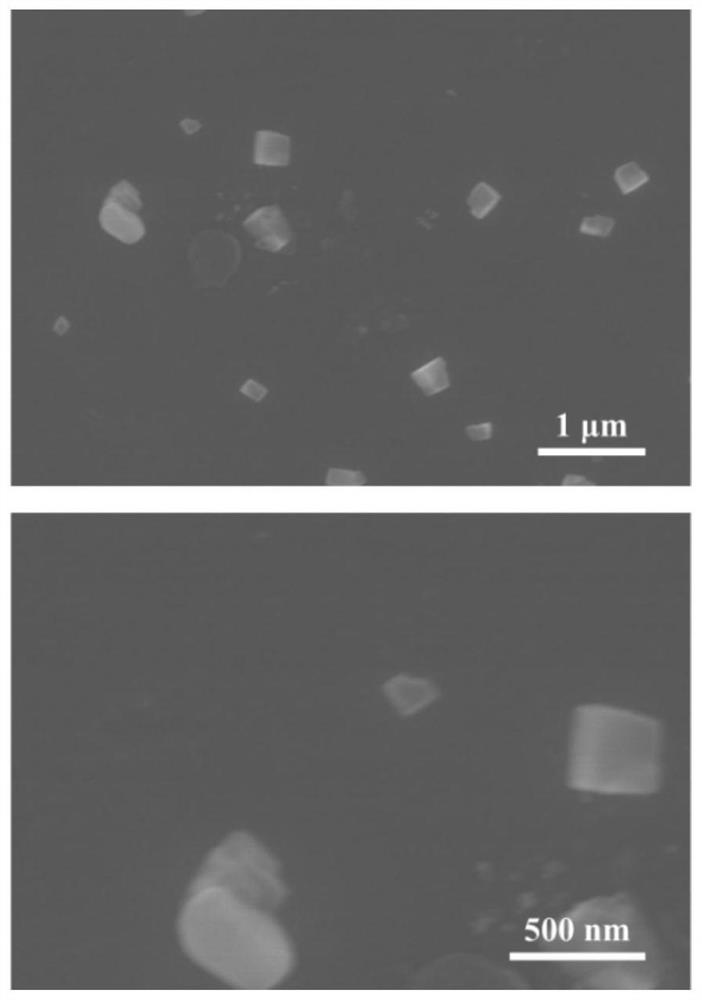

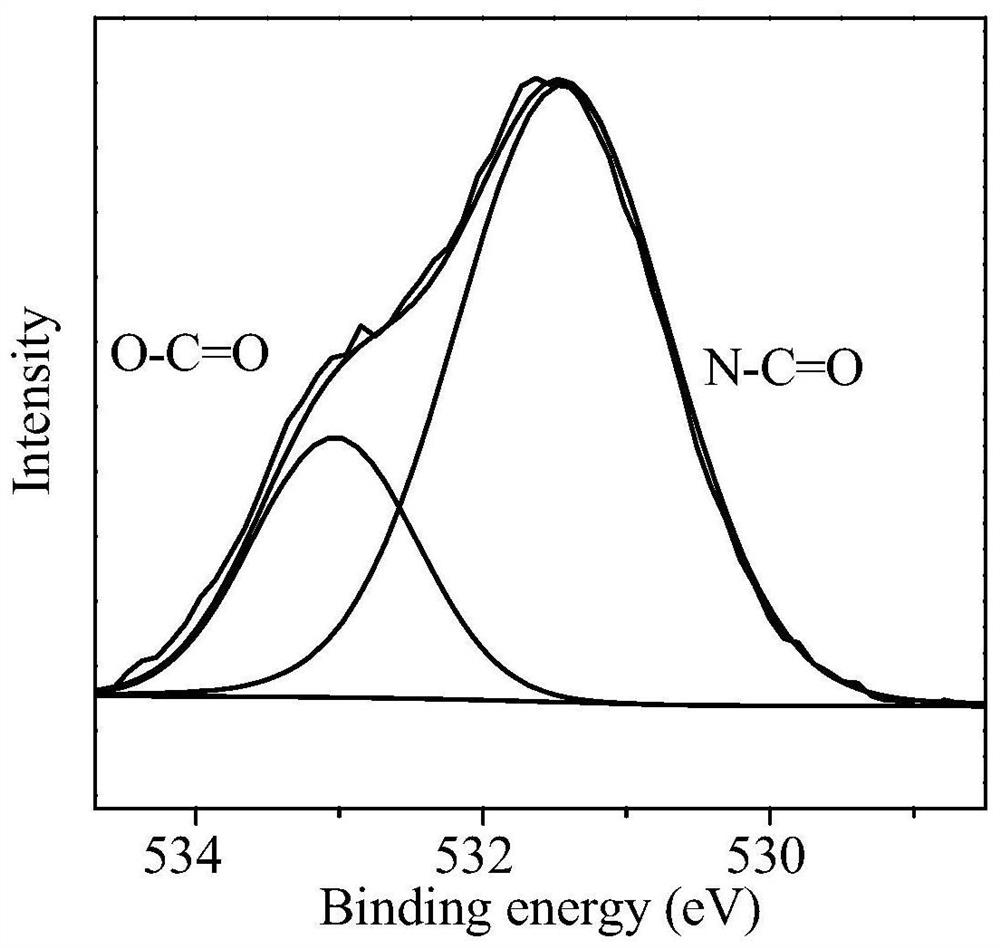

[0038] The substrate is polysulfone flat membrane (225cm 2 ), monomer A is piperazine (PIP), and monomer B is trimesoyl chloride (TMC).

[0039] Preparation:

[0040] (1) Preparation of substrates containing diamine monomers:

[0041] Add 20 mg of piperazine (PIP), a diamine monomer, into 20 mL of deionized water and stir to disperse. After fully dissolving, piperazine (PIP) solution is obtained. The piperazine (PIP) solution was evenly coated on the surface of the substrate, and dried at 80° C. to obtain the piperazine (PIP)-containing substrate.

[0042] (2) Preparation of polyamide membrane by gas phase polymerization:

[0043] Put 0.2g trimesoyl chloride (TMC) into the bottom of the container, put the substrate containing piperazine (PIP) prepared in step (1) into the container, piperazine (PIP) and trimesoyl chloride (TMC) do not direct contact occurs. Seal the reaction vessel and heat it at 50°C to vaporize trimesoyl chloride (TMC) for gas-phase polymerization for 2...

Embodiment 2

[0046] The substrate is polysulfone flat membrane (225cm 2 ), monomer A is m-phenylenediamine (MPD), and monomer B is trimesoyl chloride (TMC).

[0047] Preparation:

[0048] (1) Preparation of substrates containing diamine monomers:

[0049] Add 50 mg of diamine monomer m-phenylenediamine (MPD) into 20 mL of methanol and stir to disperse, and fully dissolve to obtain m-phenylenediamine (MPD) solution. The m-phenylenediamine (MPD) solution was evenly coated on the surface of the substrate, and dried at 60° C. to obtain the m-phenylenediamine (MPD)-containing substrate.

[0050] (2) Preparation of polyamide membrane by gas phase polymerization:

[0051] Put 0.5g trimesoyl chloride (TMC) into the bottom of the container, put the substrate containing m-phenylenediamine (MPD) prepared in step (1) into the container, m-phenylenediamine (MPD) and trimesoyl chloride (TMC) No direct contact occurs. The reaction vessel was sealed and heated at 50° C. to vaporize trimesoyl chloride...

Embodiment 3

[0053] The substrate is polyethersulfone flat membrane (225cm 2 ), monomer A is p-phenylenediamine (PPD), and monomer B is isophthaloyl chloride (IPC).

[0054] Preparation:

[0055] (1) Preparation of substrates containing diamine monomers:

[0056] Add 100 mg of diamine monomer p-phenylenediamine (PPD) into 25 mL of ethanol, stir and disperse, and obtain a p-phenylenediamine (PPD) solution after fully dissolving. The p-phenylenediamine (PPD) solution is evenly coated on the surface of the substrate, and dried at 100° C. to obtain a substrate containing p-phenylenediamine (PPD).

[0057] (2) Preparation of polyamide membrane by gas phase polymerization:

[0058] 0.6g isophthaloyl chloride (IPC) is put into the bottom of the container, and the substrate containing p-phenylenediamine (PPD) prepared in step (1) is put into the container, and p-phenylenediamine (PPD) and m-phenylenediamine Formyl chloride (IPC) does not come into direct contact. The reaction vessel was sealed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com