A kind of preparation method of metal cluster-based crystalline porous material

A technology of metal clusters and porous materials, applied in chemical instruments and methods, improvement of process efficiency, and other chemical processes, can solve problems such as not being able to greatly improve the performance of COFs, and achieve improved framework stability, high stability, catalytic The effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (1) PzPhCHO-Cu 3 preparation of

[0049] Weigh 20 mg (0.1 mmol) of 4-(3,5-dimethyl-1H-pyrazol-4 base) benzaldehyde and 7.2 mg (0.05 mmol) of cuprous oxide into a 10 mL hard glass tube, add 4 mL of Water ethanol and 0.1mL pyridine, sealed tube with hydrogen-oxygen flame machine, put it into a constant temperature oven, raise the temperature from room temperature to 140°C within 10min, keep the temperature constant for 72h, and then drop it to room temperature at a cooling rate of -5°C / h. Get PzPhCHO-Cu 3 Colorless needle-like crystals. PzPhCHO-Cu 3 The yield was 72.3%.

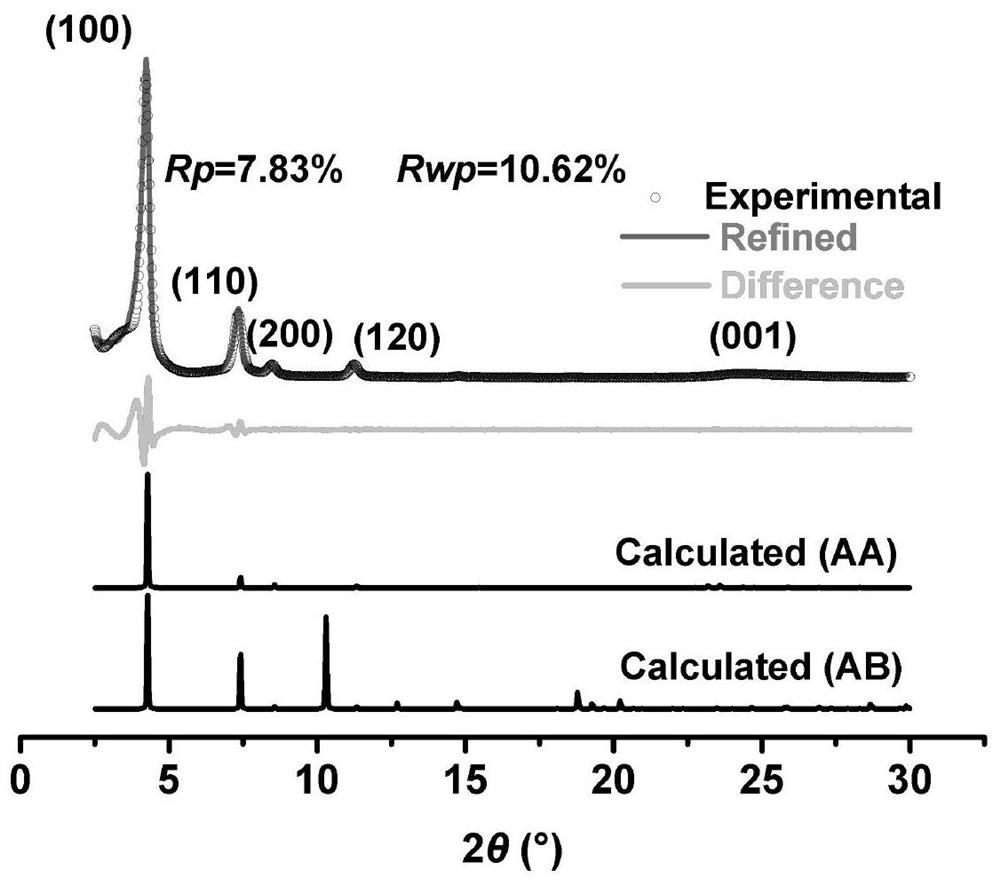

[0050] (2) Preparation of metal cluster-based crystalline porous materials

[0051] 38.45mg PzPhCHO-Cu 3 and 9.75mg of 2,2′,2″-(benzene-1,3,5-triyl)triacetonitrile were added to a Schlenk bottle filled with 2mL of o-dichlorobenzene and n-butanol (volume ratio 1:1) mixed solvent Then add 0.1mL 4M NaOH solution, freeze the solution in the Schlenk bottle with liquid nitrogen, vacuum the gas in the bo...

Embodiment 2

[0053] (1) PzPhCHO-Ag 3 preparation of

[0054] Weigh 100 mg (0.5 mmol) of 4-(3,5-dimethyl-1H-pyrazol-4 base) benzaldehyde and 7.2 mg (0.5 mmol) of silver benzoate into a 50 mL hard glass bottle, add 5 mL of methanol , 12mLTHF and 0.5mL pyridine, stirred at room temperature in the dark for 6h to obtain PzPhCHO-Ag 3 White powder. PzPhCHO-Ag 3 The yield was 82.1%.

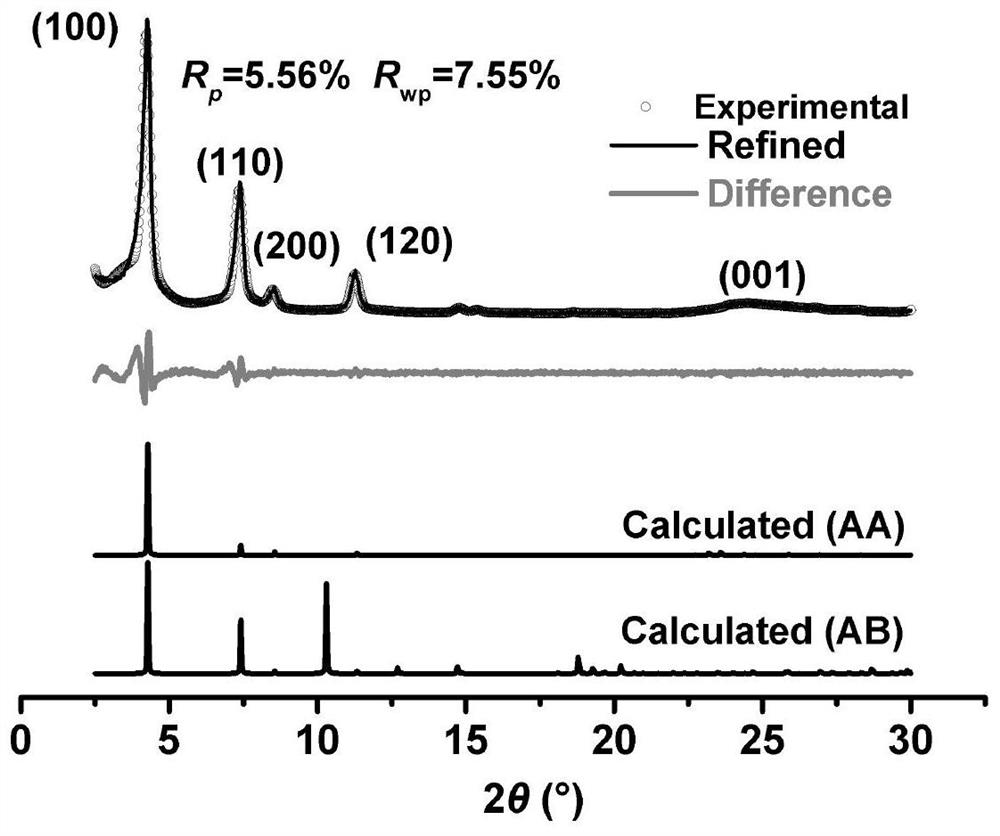

[0055] (2) Preparation of metal cluster-based crystalline porous materials

[0056] 46mg PzPhCHO-Ag 3 And 9.75mg 2,2′,2″-(benzene-1,3,5-triyl)triacetonitrile was added into a mixed solvent containing 2mL mesitylene and 1,4-dioxane (volume ratio 1:3) Then add 0.1mL 4M NaOH solution, freeze the solution in the Schlenk bottle with liquid nitrogen, vacuum the gas in the bottle, then seal the Schlenk bottle and thaw it in normal temperature water, repeat this three times , nitrogen protection, nitrogen protection, ultrasonic treatment for 30 minutes; then add a constant temperature oven, the temperature rose from r...

Embodiment 3

[0058] (1) PzPhCHO-Cu 3 preparation of

[0059] Weigh 20 mg (0.1 mmol) of 4-(3,5-dimethyl-1H-pyrazol-4 base) benzaldehyde and 7.2 mg (0.05 mmol) of cuprous oxide into a 10 mL hard glass tube, add 4 mL of Water ethanol and 0.1mL pyridine, sealed tube with hydrogen-oxygen flame machine, put it into a constant temperature oven, raise the temperature from room temperature to 140°C within 10min, keep the temperature constant for 72h, and then drop it to room temperature at a cooling rate of -5°C / h. Get PzPhCHO-Cu 3 Colorless needle-like crystals. PzPhCHO-Cu 3 The yield was 72.3%.

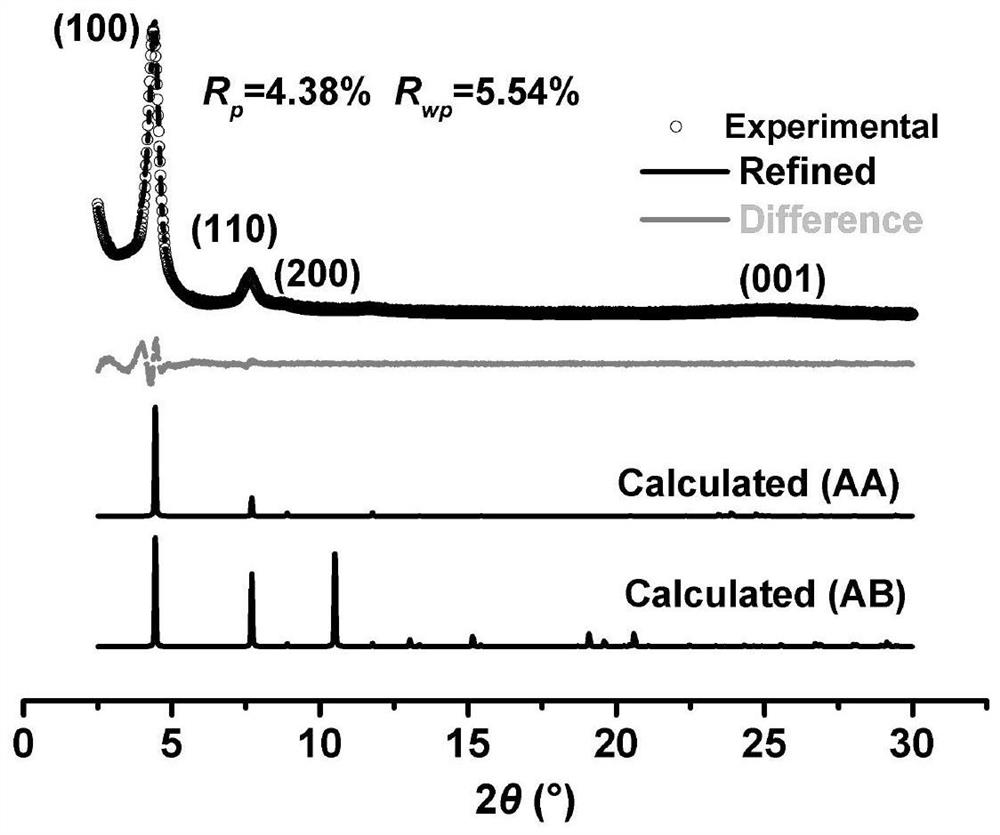

[0060] (2) Preparation of metal cluster-based crystalline porous materials

[0061] 38.45mg PzPhCHO-Cu 3 and 6.15mg of 2,4,6-trimethyl-1,3,5-triazine were added into the Schlenk bottle containing 2mL o-dichlorobenzene and n-butanol (volume ratio 1:1) mixed solvent, and then added 0.1mL 4M NaOH solution, freeze the solution in the Schlenk bottle with liquid nitrogen, vacuum the gas in the bottle, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com