Low-smoke halogen-free flame-retardant cable material and preparation method thereof

A flame-retardant cable material and raw material technology, which is applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problems of poor compatibility of inorganic flame retardants, affecting the processing performance and physical and mechanical properties of cable materials, etc. To achieve the effect of improving thermal stability, temperature resistance and compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

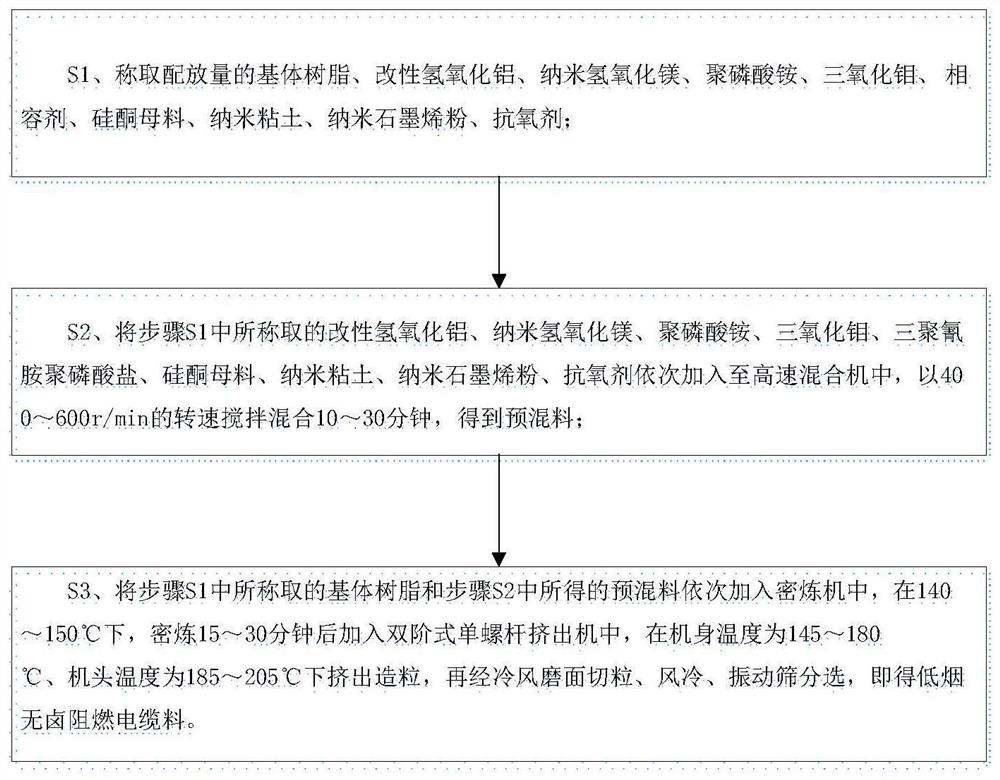

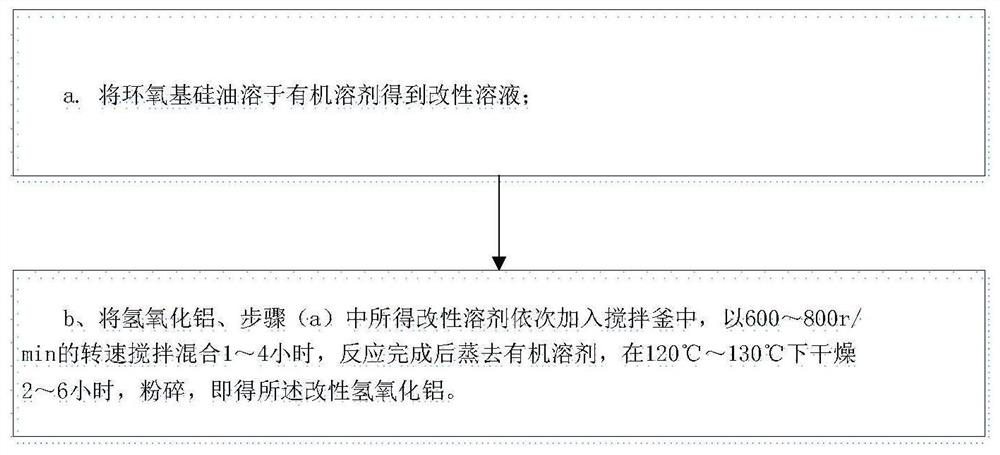

[0034] refer to figure 2 As shown, the present embodiment provides a preparation method of modified aluminum hydroxide, comprising the following steps:

[0035] a. dissolving epoxy-based silicone oil in an organic solvent to obtain a modified solution;

[0036] b. Add aluminum hydroxide and the modified solution obtained in step (a) into the stirring tank in turn, stir and mix at a speed of 800r / min for 3 hours, evaporate the organic solvent after the reaction is completed, dry at 125°C for 4.8 hours, and pulverize , that is, modified aluminum hydroxide.

[0037] Wherein, the mass fraction of epoxy-based silicone oil in the modified solution obtained in step (a) is 18%; the mass ratio of aluminum hydroxide to modified solution in step (b) is 1:0.022.

[0038] Wherein, the organic solvent in this embodiment is absolute ethanol.

Embodiment 2

[0040] refer to figure 1 As shown, this embodiment provides a low-smoke halogen-free flame-retardant cable material, which is made of the following raw materials: 100g of matrix resin, 50g of modified aluminum hydroxide, 51g of nano-magnesium hydroxide, 12g of ammonium polyphosphate, trioxide Molybdenum 1g, compatibilizer 15g, silicone masterbatch 0.4g, nanoclay 1g, nanographene powder 5g, antioxidant 0.5g;

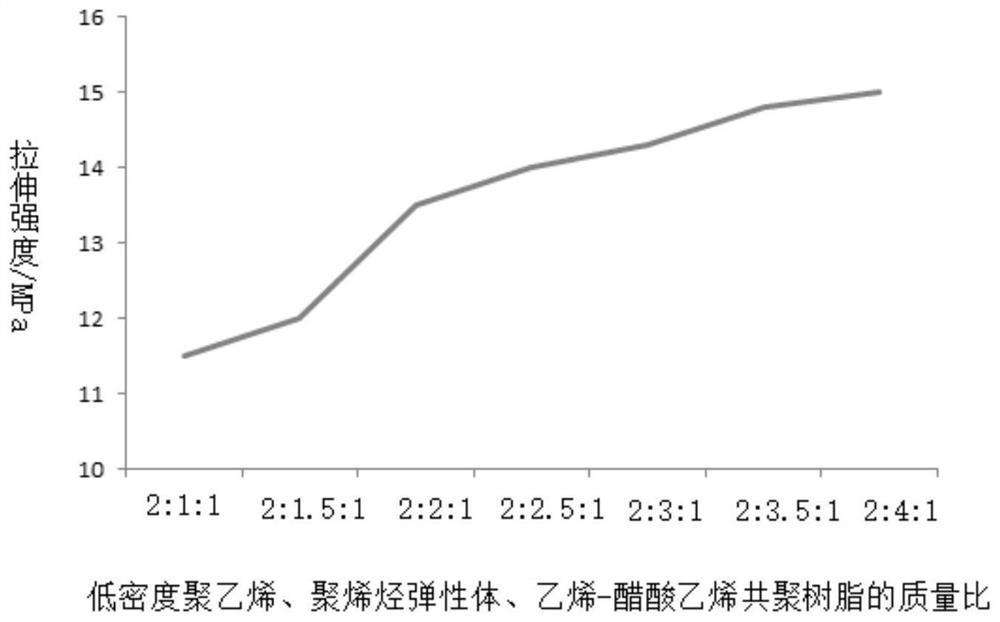

[0041] Among them, the matrix resin is composed of low-density polyethylene, polyolefin elastomer and ethylene-vinyl acetate copolymer resin, and the mass ratio of low-density polyethylene, polyolefin elastomer and ethylene-vinyl acetate copolymer resin is 2:2:1.

[0042] Wherein, the modified aluminum hydroxide in this example is the modified aluminum hydroxide prepared in Example 1.

[0043] Wherein, the antioxidant in this embodiment is composed of 1,1,3-tris(2-methyl-4-hydroxyl-5-tert-butylphenyl)butane and dilauryl thiodipropionate mixture. Wherein, the mass ratio o...

Embodiment 3

[0051] refer to figure 1 As shown, this embodiment provides a low-smoke halogen-free flame-retardant cable material, which is made of the following raw materials: 100g of matrix resin, 82g of modified aluminum hydroxide, 80g of nano-magnesium hydroxide, 35g of ammonium polyphosphate, trioxide Molybdenum 3g, compatibilizer 20g, silicone masterbatch 1.8g, nanoclay 10g, nanographene powder 7g, antioxidant 2.8g;

[0052] Among them, the matrix resin is composed of low-density polyethylene, polyolefin elastomer and ethylene-vinyl acetate copolymer resin, and the mass ratio of low-density polyethylene, polyolefin elastomer and ethylene-vinyl acetate copolymer resin is 2:2:1.

[0053] Wherein, the modified aluminum hydroxide in this example is the modified aluminum hydroxide prepared in Example 1.

[0054] Wherein, the antioxidant in this embodiment is composed of 1,1,3-tris(2-methyl-4-hydroxyl-5-tert-butylphenyl)butane and dilauryl thiodipropionate mixture. Wherein, the mass rati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com